Bundled half-grouting constraint pulp anchor connecting method

A connection method and clustering technology, applied in the direction of building and building structure, can solve the problems of difficult installation and construction, large number of reserved reinforcement holes, and difficult assembly, so as to reduce the difficulty of construction and installation, improve efficiency, Assemble simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

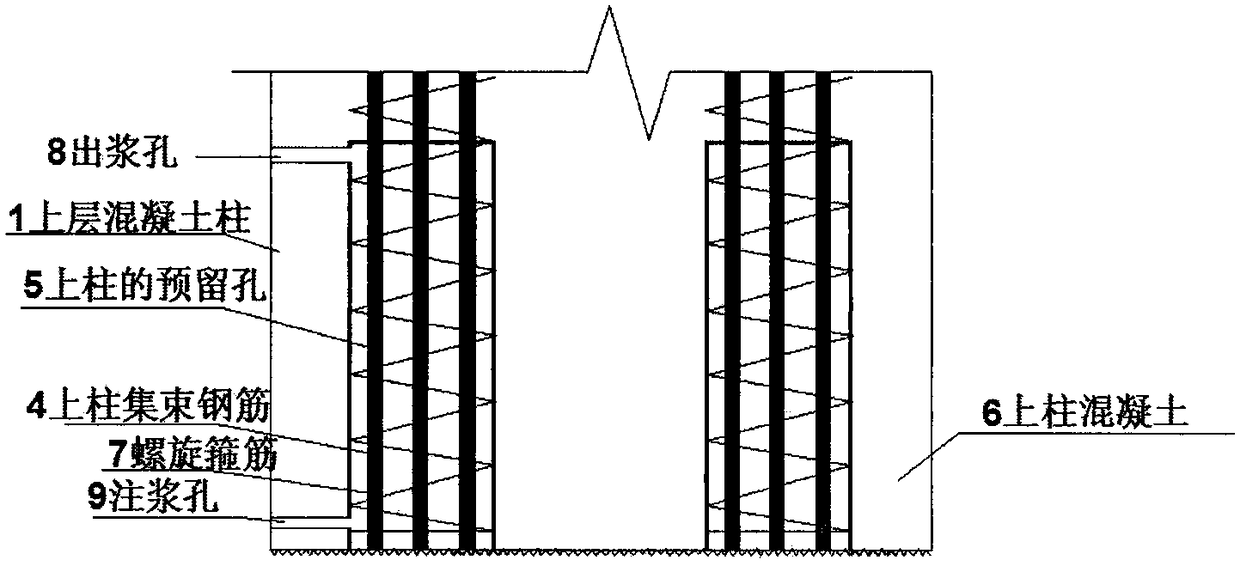

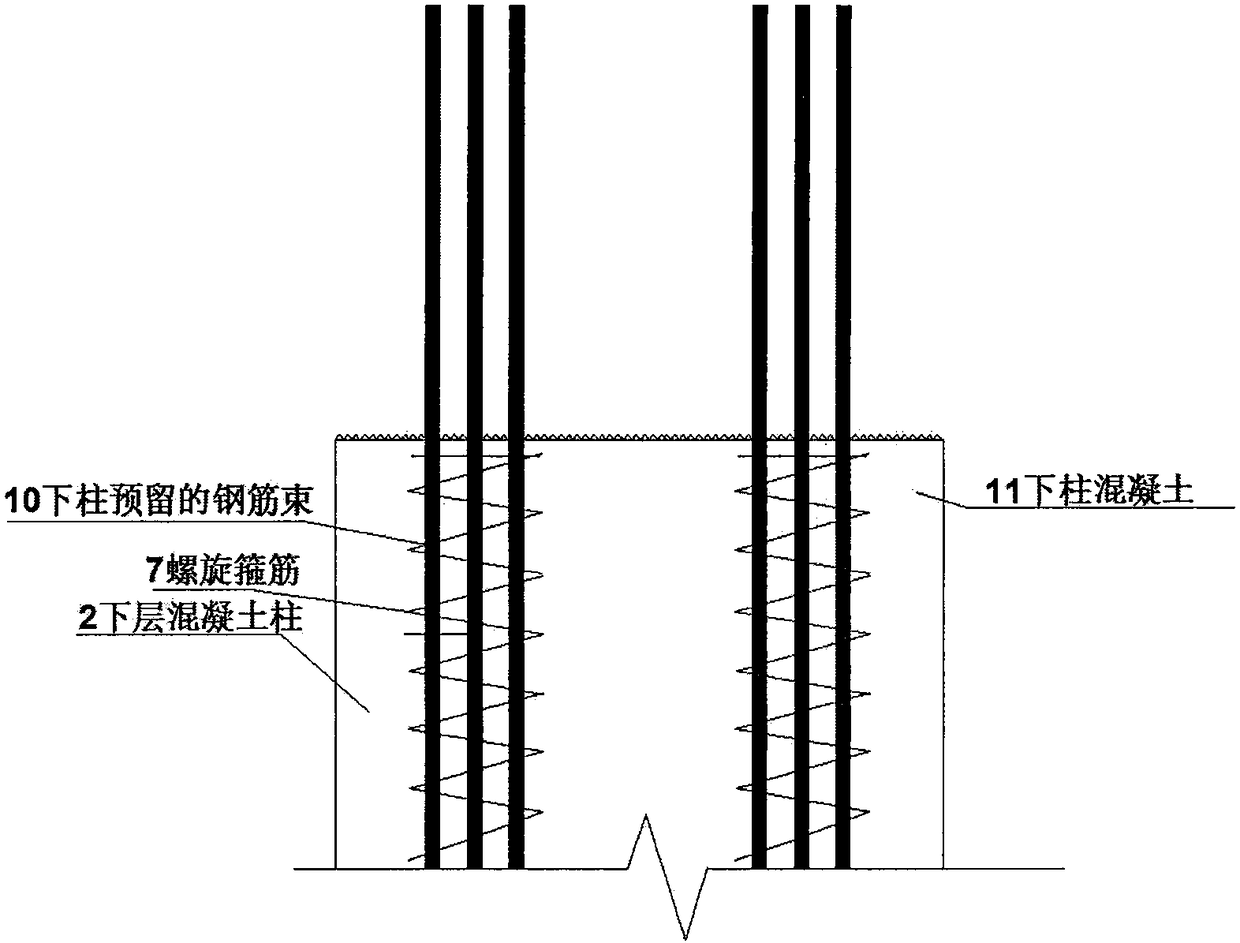

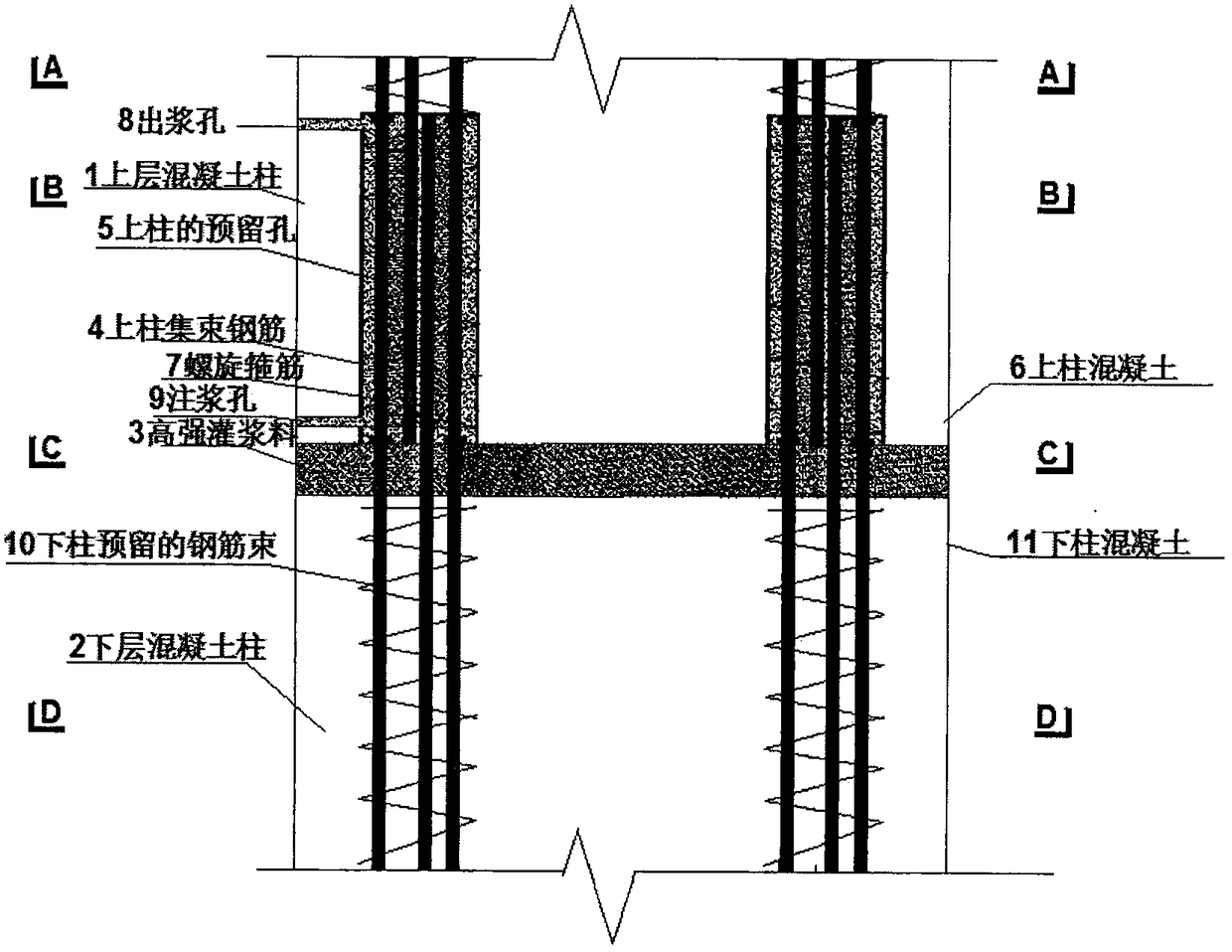

[0019] What the present invention adopts is the grout-anchor connection method of cluster semi-grouting restraint, which is composed of the upper concrete column, the lower concrete column, and the grouting between the upper and lower prefabricated concrete columns; Retained holes, upper column concrete, spiral stirrups, grout outlet at the upper end of the upper column reserved hole, and grouting port at the lower end of the upper column reserved hole; the lower concrete column includes the reserved cluster steel bars for the lower column, lower column concrete, spiral Stirrups. The installation method is as follows: align the reserved holes of the upper concrete column directly with the reserved steel beams of the lower column and drop it, use a special adjustment device to adjust the position and verticality of the column, fix it after alignment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com