Steel bar connection grouting-free sleeve device of fabricated concrete structure

A technology for concrete structures and grouting sleeves, which is applied to structural elements, building components, building structures, etc., can solve the problems of waste of grouting materials, insufficient anchoring force of steel bars, and difficult on-site control, so as to increase the contact surface area and reduce the Anchoring length, good effect of fixing steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

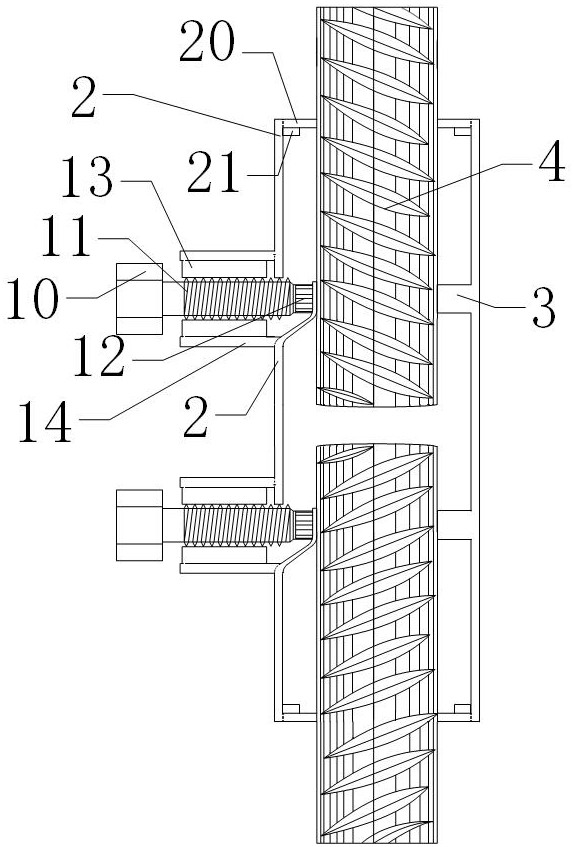

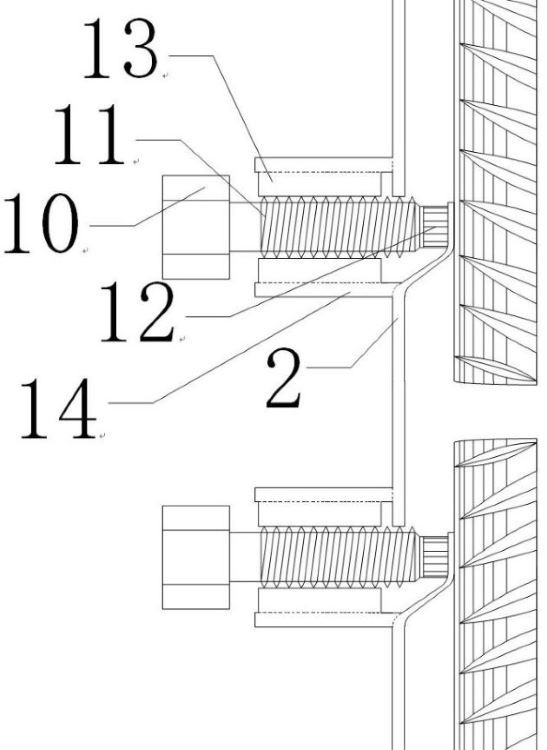

[0026] The content of the present invention is an assembly-type grout-free sleeve connection steel bar device, which is characterized in that it includes high-strength bolts 1, sleeves 2, and bosses 3, such as figure 1 The shown sleeve 2 includes a sealing ring 20 and a card groove 21, such as figure 2 The shown high-strength bolt 1 includes a nut 10, a screw rod 11, a torx head 12, a threaded arm 13, and a high-strength steel pipe 14, and the high-strength bolt is made of high-strength steel.

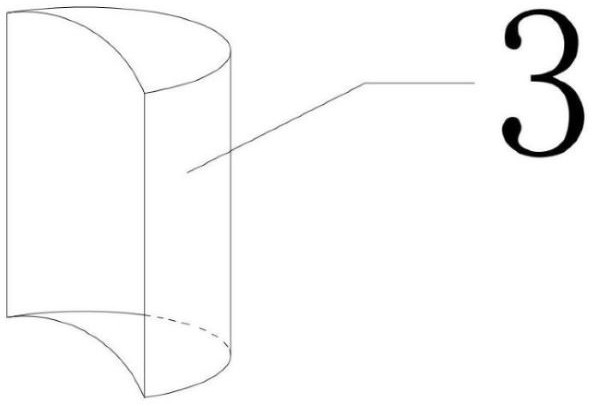

[0027] Such as image 3 The shown boss 3 is fixed on the inner wall on the right side of the sleeve 2, connected with the sleeve 2, and is crescent-shaped, and its radian corresponds to the radian of the steel bar. The boss 3 is made of steel with a low yield point.

[0028] The device of the present invention has a certain construction effect i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com