Fabricated concrete structure beam-column dry-wet combination connection structure and implementation method

A concrete structure and combined connection technology, which is applied in the direction of building structure and construction, can solve the problems of lifting, inconvenient installation, difficulty in lifting in place, and large number of steel bars, and achieve the effect of saving process links and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

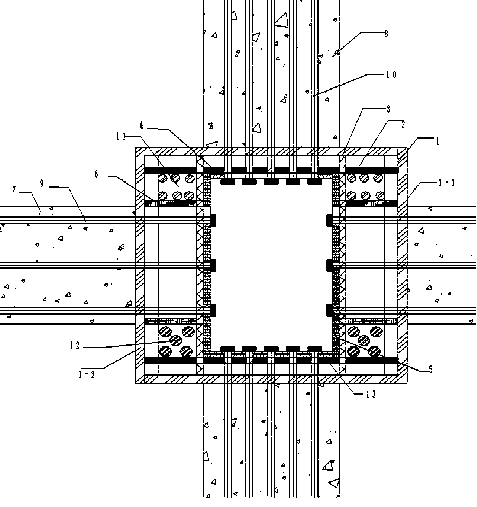

[0043] Taking the prefabricated concrete frame structure as an example, the beam adopts a prefabricated composite beam, and the maximum size of the beam section is 300×900. -28, the beam-column joint adopts a dry-wet combination connection structure of a prefabricated concrete structure beam-column of the present invention.

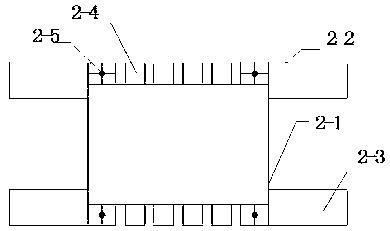

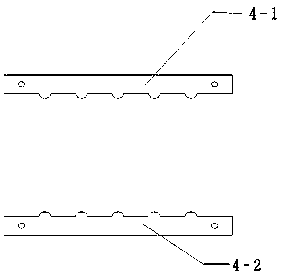

[0044] Such as Figure 1-Figure 3 As shown, a prefabricated concrete structure beam-column dry-wet combined connection structure, the intersection of the transverse beam 7 and the longitudinal beam 8 is the node core area, and the node core area includes a cylinder cavity structure. The cavity structure includes an outer cylinder 1 and an inner cylinder. The outer cylinder 1 and the inner cylinder form a square ring cavity. The four corners of the square ring cavity are equipped with longitudinal steel bars I11 at the corners of the columns, longitudinal steel bars II12 at the corners of the columns, and transverse beams. 7. The transverse beam longitudi...

Embodiment 2

[0058] Taking the prefabricated concrete frame structure as an example, the beam adopts the prefabricated beam, the maximum size of the beam section is 300×1200, the column adopts the prefabricated column, the column section size is 700-1000mm, the longitudinal force reinforcement of the beam column adopts HRB500, and the diameter is 22-28mm , The beam-column joint adopts a dry-wet combination connection structure of a prefabricated concrete structure beam-column of the present invention.

[0059] An implementation method of a prefabricated concrete structure beam-column dry-wet combined connection structure, using a prefabricated concrete structure beam-column dry-wet combined connection structure in Embodiment 1;

[0060] Step 1: splitting of concrete frame structure prefabricated components;

[0061] According to the design drawings, use the BIM information model of REVIT or PLANBAR to split the concrete frame structure into horizontal beam body, longitudinal beam body, upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com