A pipe pier and bearing platform connecting structure and a construction method

A technology for connecting structures and pipe piers, which is applied to bridge parts, bridges, buildings, etc., can solve the problem of pipe piers increasing, and achieve the effect of reducing the overall thickness and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

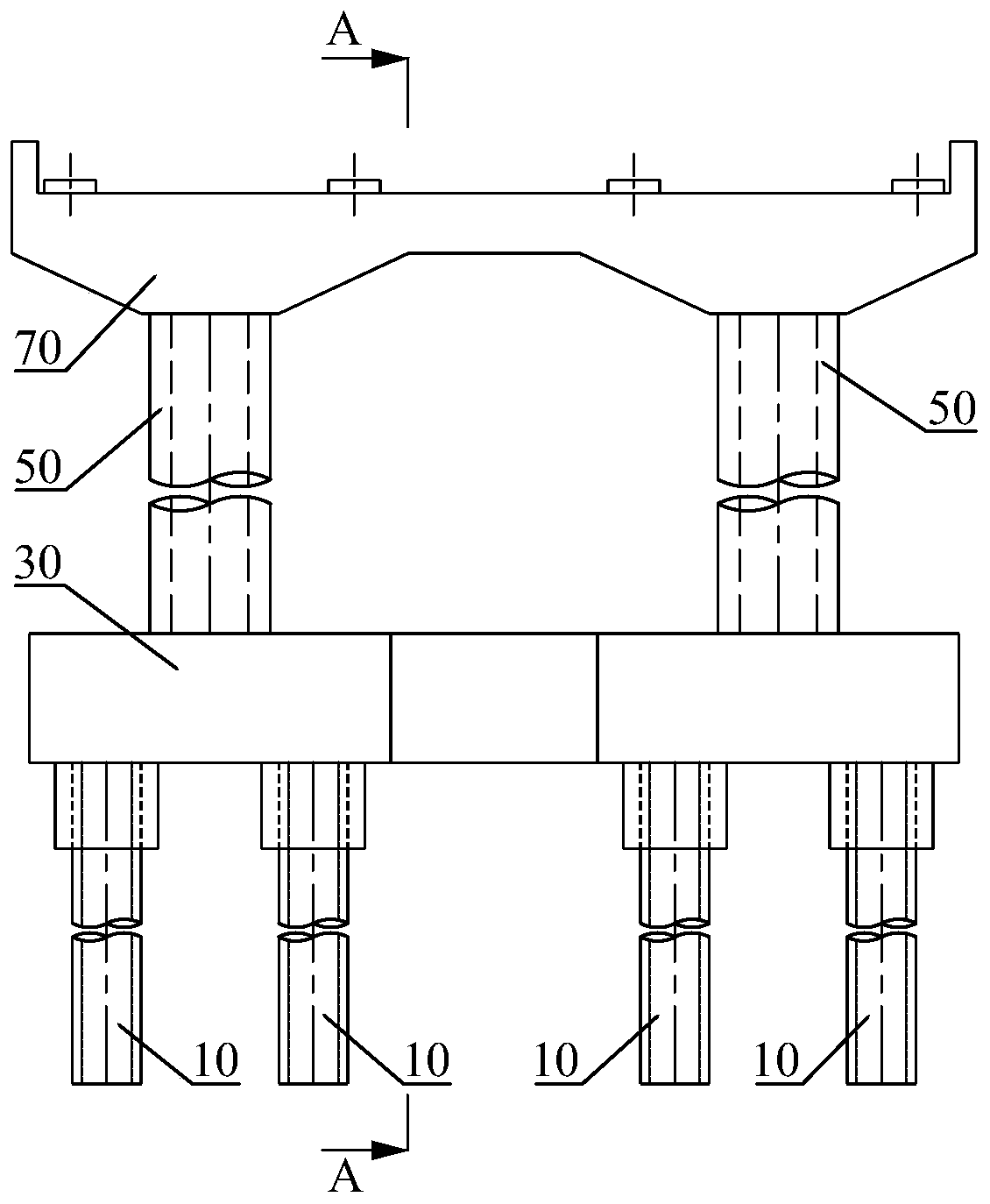

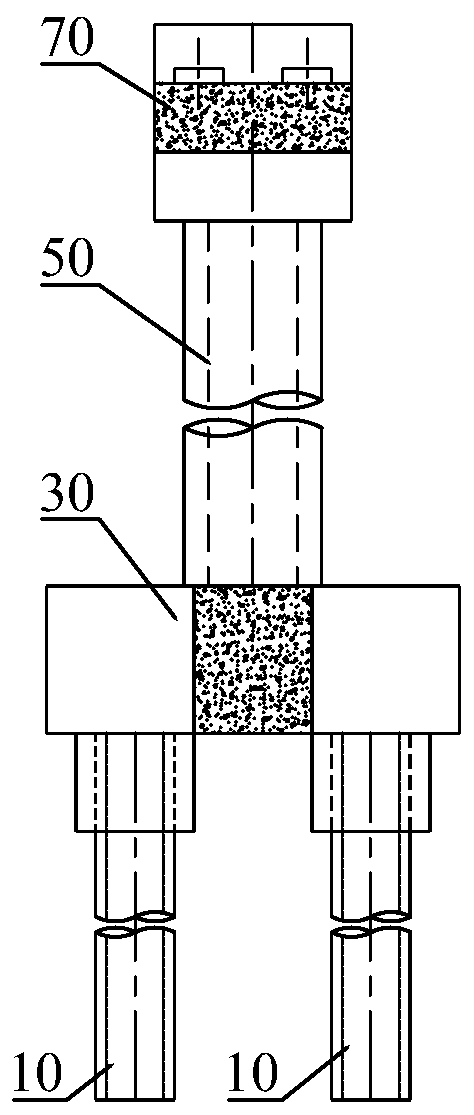

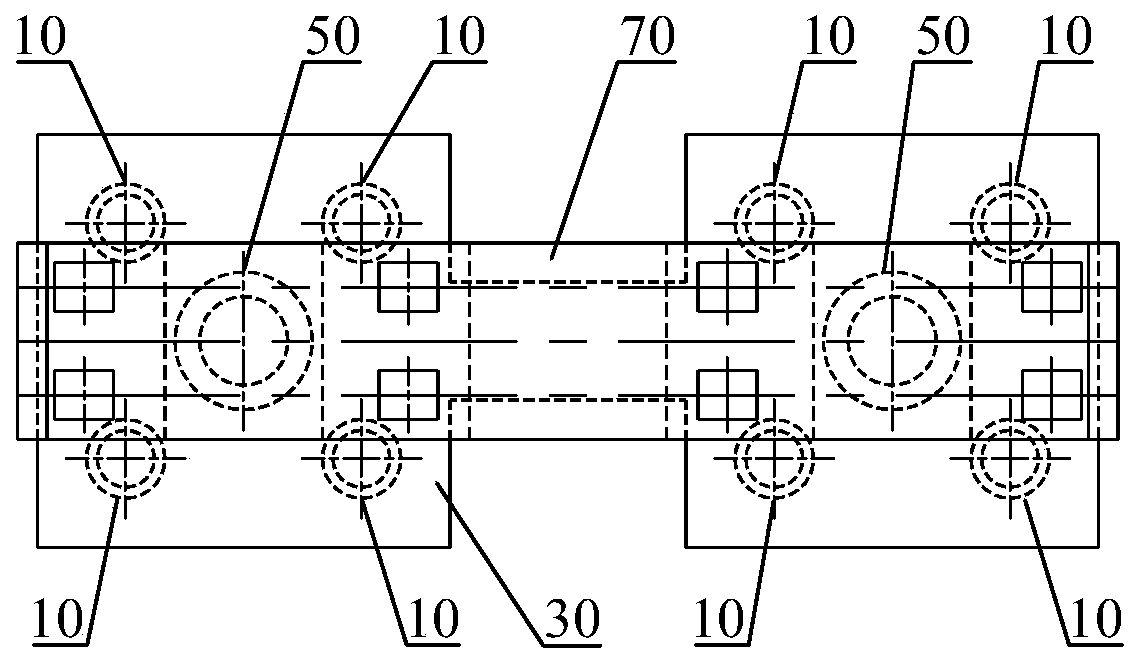

[0036] see figure 1 , figure 2 with image 3 , the prefabricated assembled pier sequentially includes pile foundation 10, cast-in-place cap 30, prefabricated pipe pier 50 and prefabricated cap beam 70 from bottom to top; 10 platform, pile foundation 10 and cast-in-place cap 30 are buried below the ground; several prefabricated pipe piers 50 are vertically connected above the cast-in-place cap 30; The cap beam 70 is transversely connected to several prefabricated pipe piers 50 . In the illustrated embodiment, eight pile foundations 10 are arranged below the cast-in-place cap 30, and the eight pile foundations 10 are distributed in four rows in two rows; The root prefabricated pipe piers 50 are distributed side by side.

[0037] Please refer to Figure 4 with Figure 5, the prefabricated pipe pier 50 is a prefabricated hollow ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com