Hydropower station draft tube structure

A technology for draft tubes and hydropower stations, which is applied in the directions of hydropower stations, hydroelectric power generation, water conservancy projects, etc., can solve the problems of increasing the amount of excavation works and concrete works of the bottom plate, affecting the normal use of draft tubes, and large temperature stress of concrete, etc. The effect of reducing the amount of concrete works, reducing the amount of excavation works, and reducing the lifting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

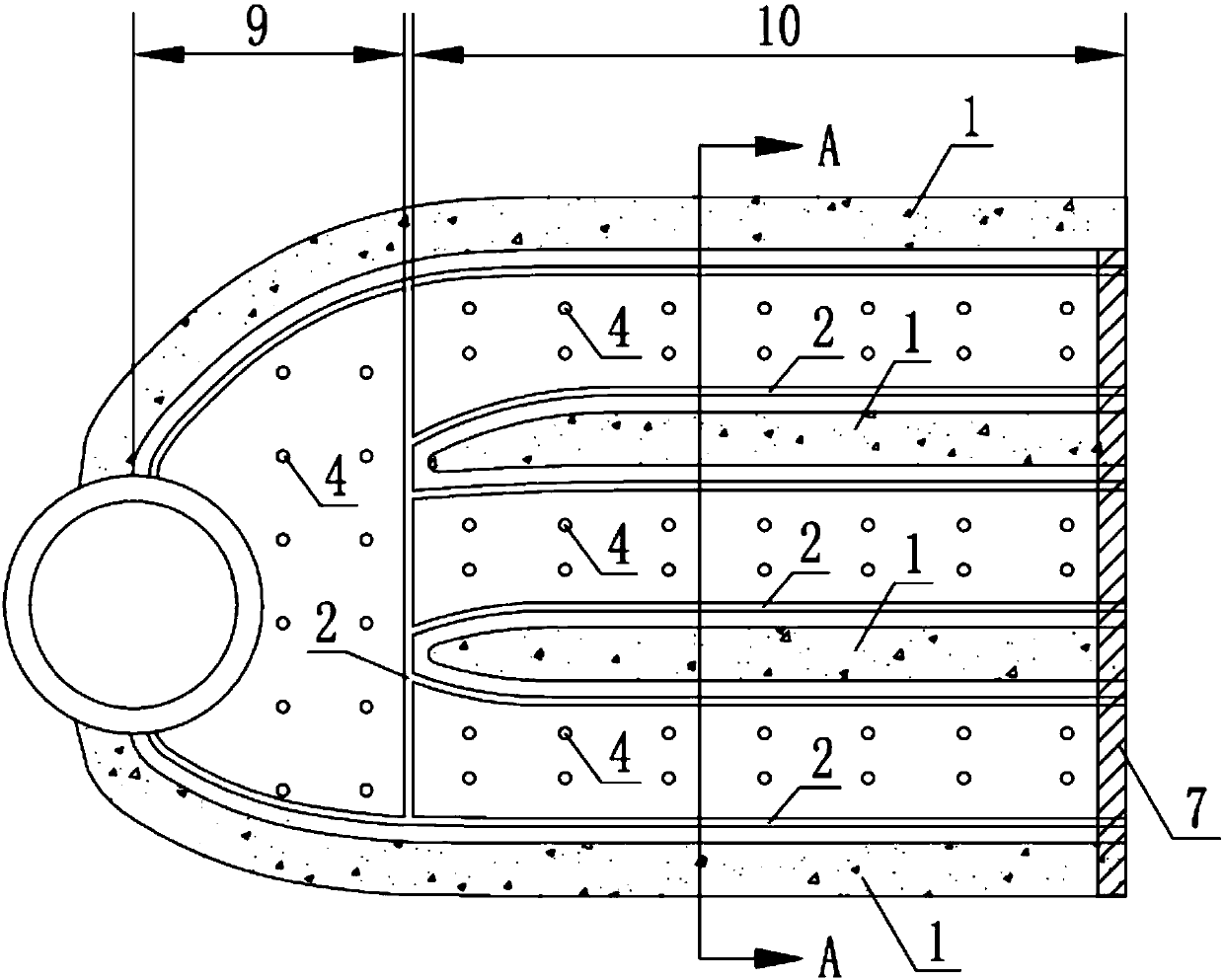

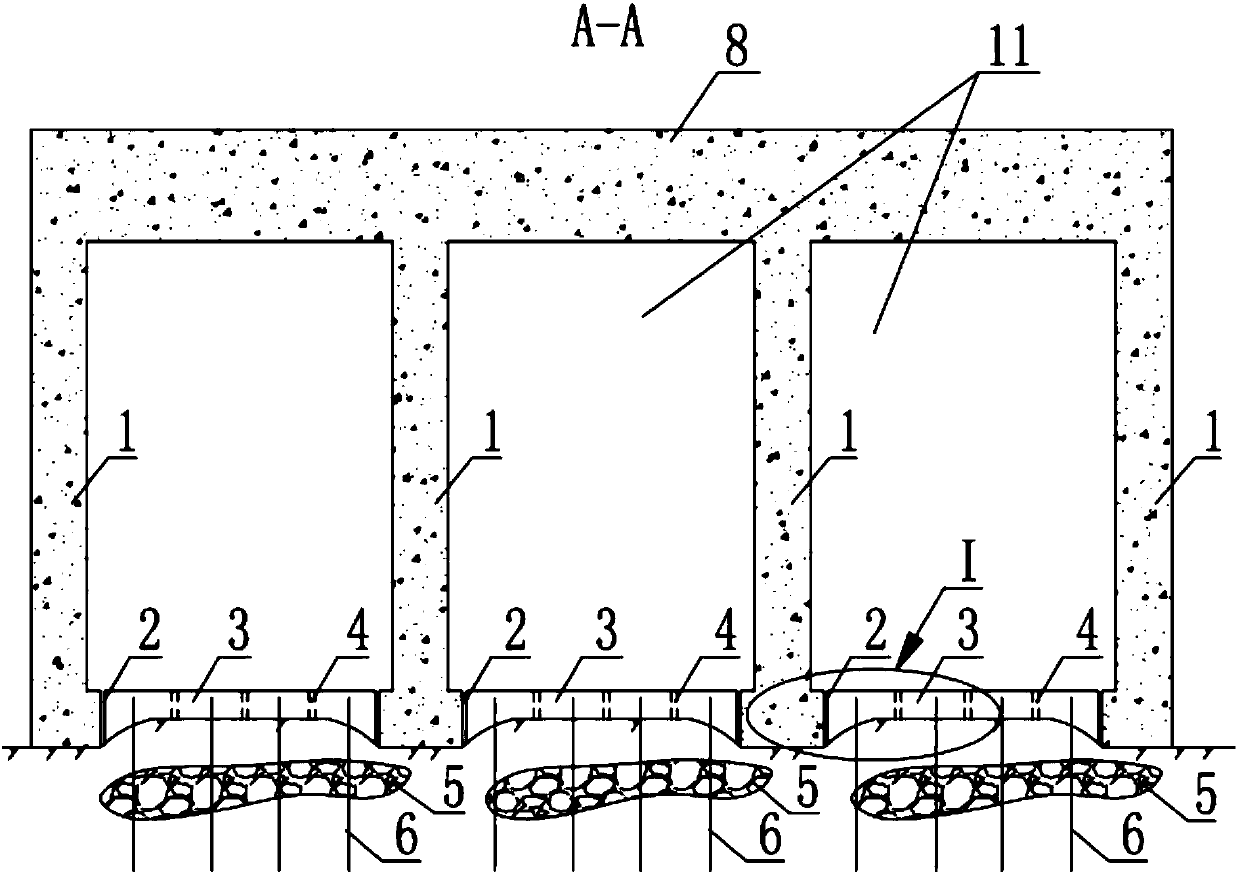

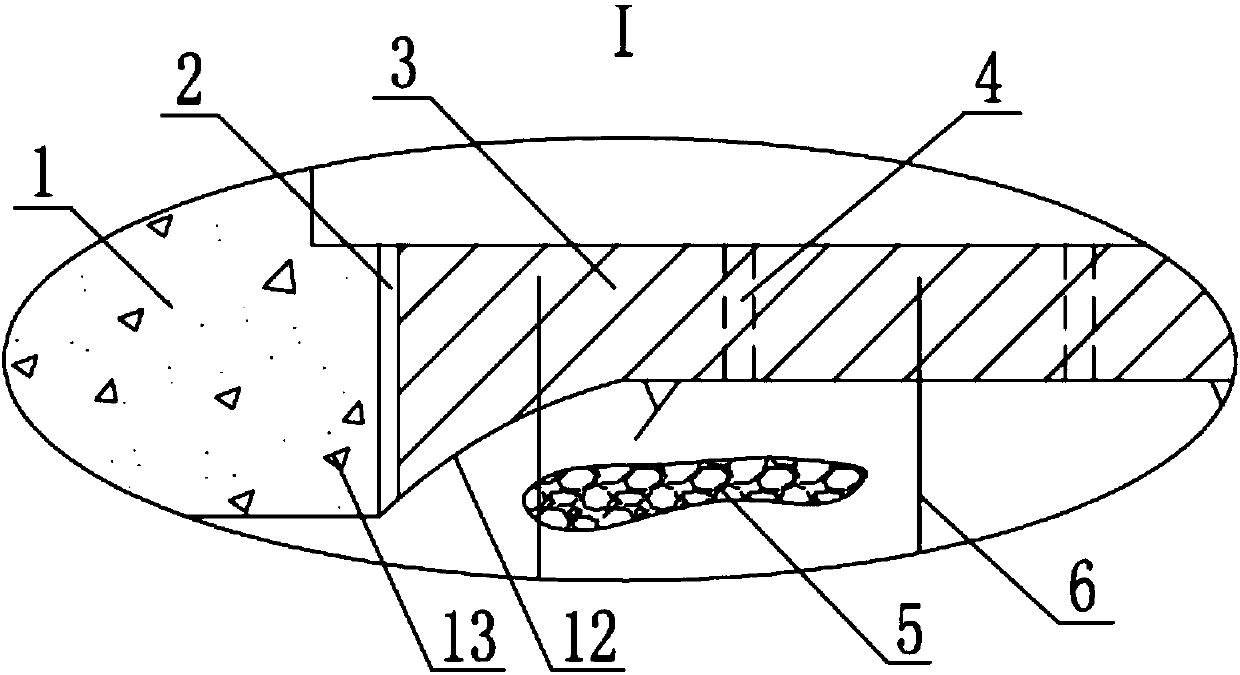

[0032] Such as figure 1 to attach Figure 4 As shown in , the draft tube structure of the hydropower station in the present invention refers to the water guide channel structure immediately adjacent to the outlet of the impact turbine runner, which guides the water flowing out of the turbine runner to connect with the downstream tail water. The draft tube structure of a hydropower station according to the present invention includes a pier wall 1 and a bottom plate 3 ; wherein, a structural joint 2 is provided between the bottom plate 3 and the pier wall 1 . The function of the structural joint 2 is to separate the base plate 3 from the pier wall 1, so that the concentrated load on the pier wall 1 can no longer be distributed by the base plate, thereby reducing the internal stress of the base plate 3 and reducing its required thickness. Reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com