Water pipe, strip material, method and apparatus for manufacturing water pipe

A technology for water pipes and strips, applied in the field of water pipes, can solve the problems of unacceptable manufacturing costs, insufficient ability to resist external pressure, and increased wall thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

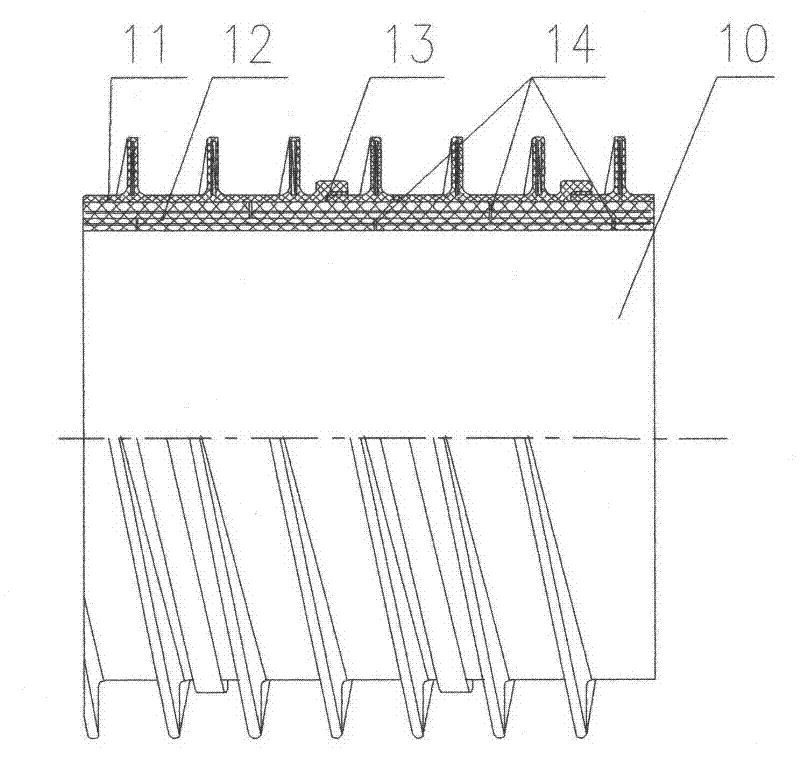

[0042] figure 1 The illustrated water pipe 10 includes a reinforced composite outer pipe 11 formed by helically winding, and a reinforced composite inner pipe 12 formed by helically winding.

[0043] The outer tube 11 is a metal-reinforced plastic composite corrugated pipe structure or a pipe structure with metal-reinforced plastic composite vertical ribs. The inner liner 12 is formed by at least two layers of fiber-reinforced plastic composite strips that are continuously helically wound along the inner wall of the outer tube and attached to the inner wall of the outer tube. The inner liner covers the spirally wound joint of the outer tube. seam13. When the inner liner 12 is compositely formed from multiple layers of fiber-reinforced plastic composite tapes, the wrapping seams 14 of the tapes of each layer are covered by the tapes of the adjacent layers.

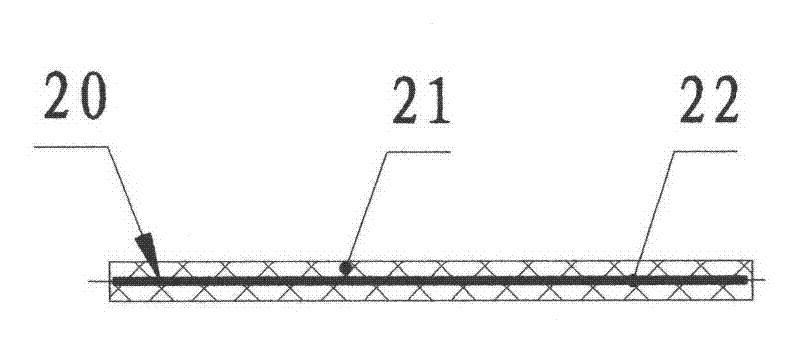

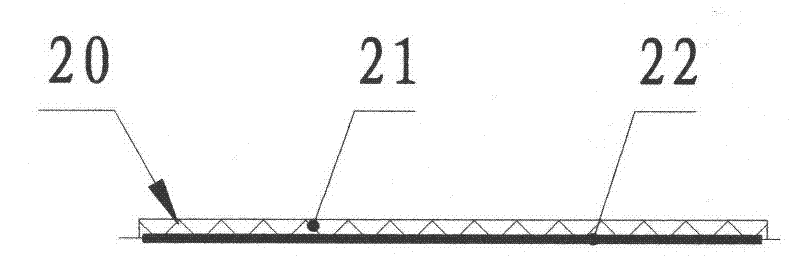

[0044] figure 2 A tape 20 forming a liner for a water pipe is shown, comprising a plastic tape base layer 21 and a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com