Method for producing a hot-forming tool and hot-forming tool with wear protection

A thermoforming and mold technology, which is applied in the field of manufacturing thermoforming molds used for thermoforming of sheet metal components, can solve the problems of material wear resistance not meeting the requirements, and achieve the effect of economical matrix cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the figures, identical or similar parts / components have been given the same designations, wherein corresponding or comparable advantages can be achieved even if the description is not repeated for the sake of simplicity.

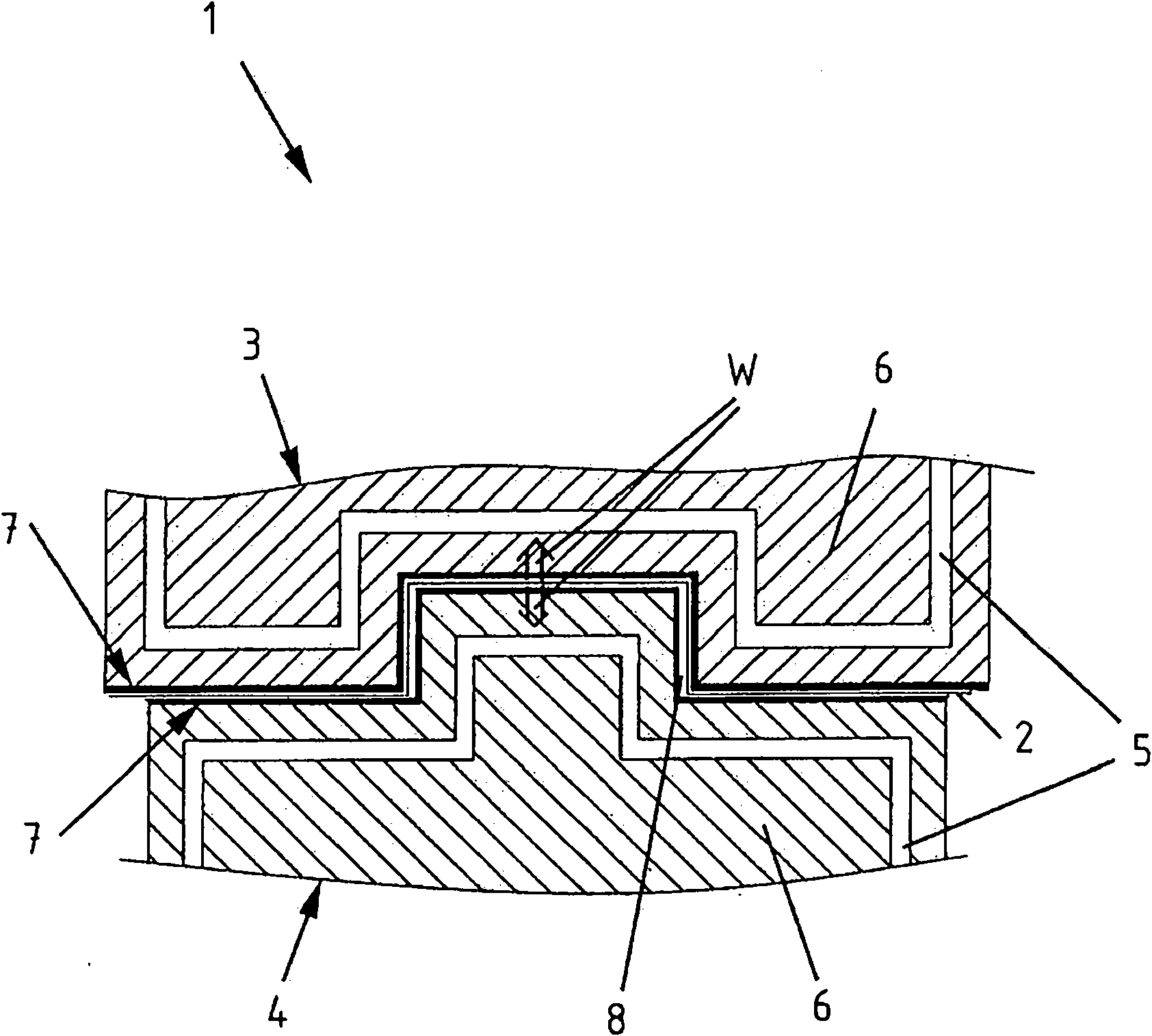

[0039] figure 1A cross-sectional view of a thermoforming die 1 according to the invention is shown. The thermoforming tool 1 is shown in the closed state. The deformed plate member 2 is located between the upper die 3 and the lower die 4 . The upper mold 3 and the lower mold 4 here comprise a base body 6 with cooling channels 5 . A heat removal fluid flows through these cooling channels 5 . A mold lining 7 is arranged on the base body 6 on the side of the sheet metal component. The mold lining 7 protects the base body 6 against high wear and forms the boundary of the mold cavity 8 . The heat transfer W of the sheet metal component 2 produced due to the heating of the sheet metal component 2 via the mold lining 7 to the base body 6 . Next, thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com