Casting primary standard processing method capable of balancing finishing allowance

A technology of machining allowance and processing method, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency, time-consuming, and high requirements for fitter skills, so as to facilitate rapid cutting and reduce Significant effect on production cost and economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

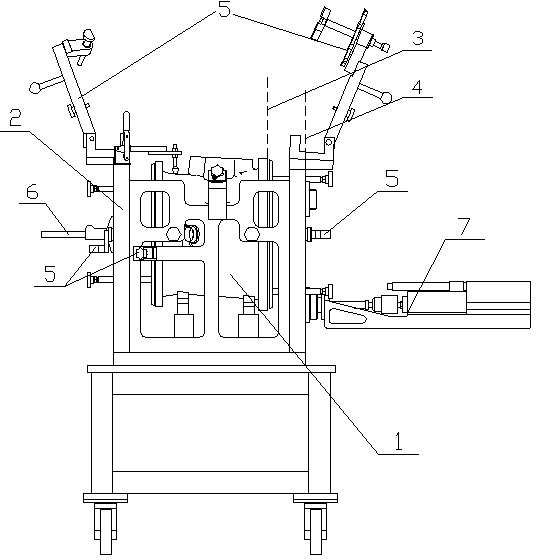

[0021] Such as figure 1 As shown, a method of initial datum processing of castings with balanced machining allowance includes the following steps:

[0022] Step 1, virtualize a standard casting and select a detection device, the frame 2 in the detection device matches the shape of the virtual standard casting, so that the machining datum plane 3 of the standard casting is parallel to the main wallboard plane 4 of the frame ;

[0023] Step 2, placing the casting 1 to be tested at the initial position in the frame 2, where the initial position is the position of the virtual standard casting in the frame 2;

[0024] Step 3: Contact or approach the surface of the casting 1 to be tested with the profile detection block 5 on the detection device, confirm the positional relationship between the casting 1 to be tested and the profile detection block 5, and judge the casting 1 to be tested Whether the machining surface allowance is qualified and uniform; the normal machining allowanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com