Cutting device for mechanical machining

A cutting device and mechanical processing technology, applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve problems affecting cutting accuracy, environmental pollution, and affecting staff observation, so as to improve cutting accuracy, facilitate observation, The effect of preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

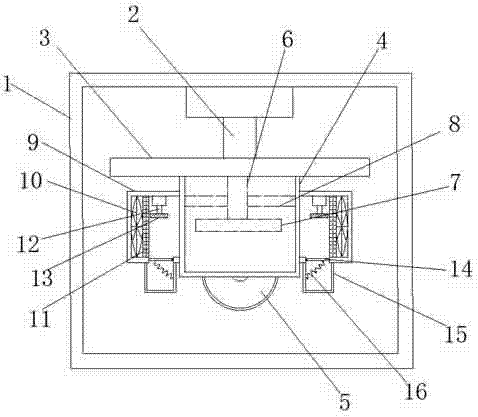

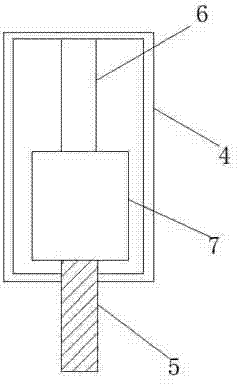

[0017] Embodiment 1: including a cutting box 1, the top inner wall of the cutting box 1 is connected with a cylinder 2, the other end of the cylinder 2 is vertically welded with a support plate 3, and the end of the support plate 3 away from the cylinder 2 is connected with a fixed box 4, and the fixed box 4 The inside is provided with a circular blade 5, and half of the circular blade 5 extends to the outside of the bottom of the fixed box 4, and the first connecting pipe 6 connected to the inner wall of the fixed box 4 top is installed directly above the circular blade 5, and the first connection The bottom end of the pipe 6 is connected with a second connecting pipe 7, and the first connecting pipe 6 and the second connecting pipe 7 are internally communicated, and the side walls on both sides of the first connecting pipe 6 are connected with symmetrically arranged suction pipes 8, and the fixed box The side walls on both sides of 4 are vertically welded with a connection bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com