Metal corrugated pipe type oil storage cabinet

A bellows type, oil conservator technology, applied in the field of transformer equipment, can solve the problems of lowering insulation level, insufficient mechanical strength, jamming, etc., achieve good pressure resistance and vacuum resistance, improve safe operation coefficient, effective volume big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

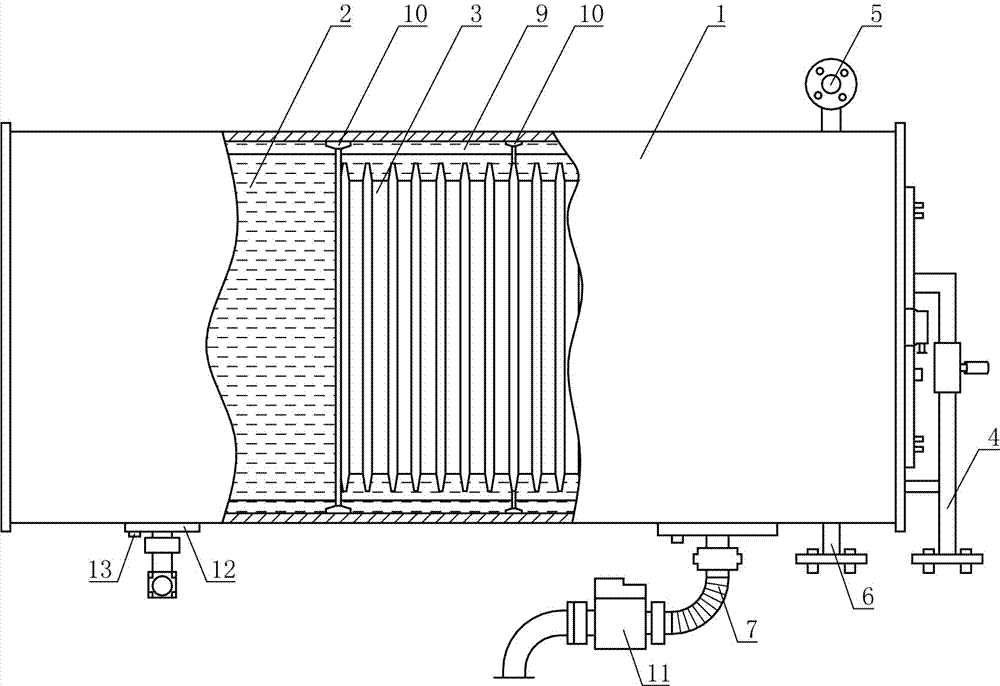

[0019] The metal bellows type oil conservator of the present invention includes a cabinet body 1, a bellows assembly 3 sealed and arranged on one side inside the cabinet body 1, a sliding guide mechanism arranged inside the side wall of the cabinet body 1, and arranged above the outside of the cabinet body 1 The exhaust port 5, the oil filling port 6 and the corrugated flexible connecting pipe 7 respectively arranged under the outside of the cabinet body 1, the oil chamber 2 formed by the inside of the cabinet body 1 and the outside of the bellows assembly 3 is connected with the inner cavity of the bellows assembly 3 The breathing port 4 communicated with the oil chamber 2, and the exhaust port 5 communicated with the oil chamber 2, wherein the sliding guide mechanism and the bellows assembly 3 are slidably connected.

[0020] When the present invention is used to compensate the volume of the transformer insulating oil, the corrugated flexible connecting pipe 7 is connected to...

example 2

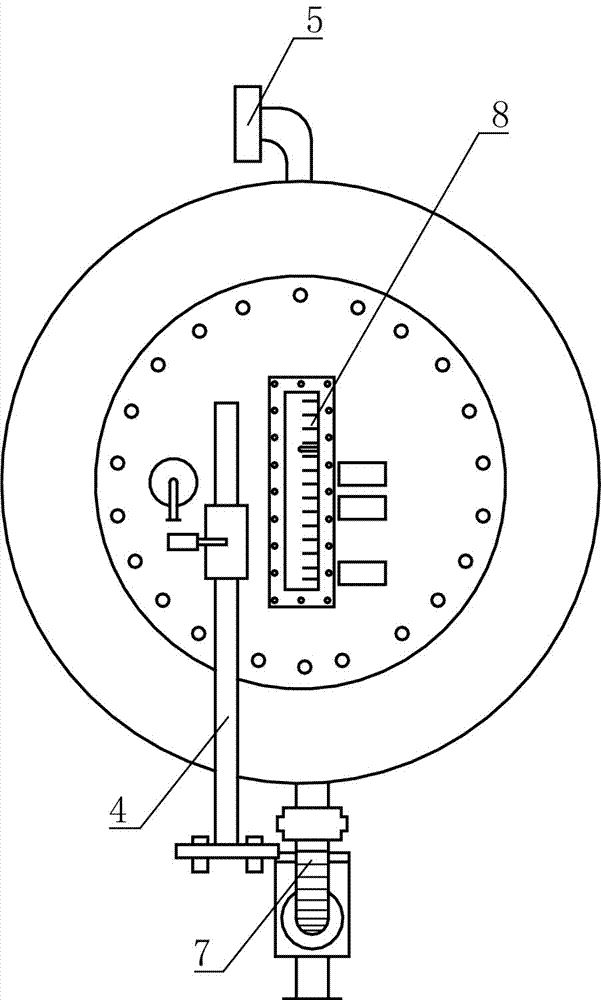

[0022] Metal bellows type oil conservator of the present invention, as figure 1 , figure 2 As shown, the cabinet body 1 has a cylindrical horizontal structure. This design is reasonable and beautiful, and the structure is relatively compact. At the same time, it can increase the effective volume of the entire oil storage tank and improve its insulation; The oil level gauge 8 of the cabinet and the oil level gauge 8 of the oil storage tank adopt the window drawstring type oil level gauge, which does not need to be installed and adjusted on site, and the drawstring structure makes the indication more intuitive, accurate and reliable, and there is no false oil level.

[0023] Wherein, the sliding guide mechanism includes slide rails 9 arranged on the upper, lower, left and right sides of the inner wall of the cabinet body 1, and the corresponding slide rails 9 are arranged on the front end cover of the bellows assembly 3 and the pipe body of the bellows assembly 3 to guide Bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com