Comprehensive performance safety test system of broken belt arresting device with buffer device

A broken belt arresting device and buffer device technology, applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of large damage to the conveyor belt, easy to block moving parts, deformation of the frame, etc., to prevent Injury accidents and the effect of improving the safe operation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

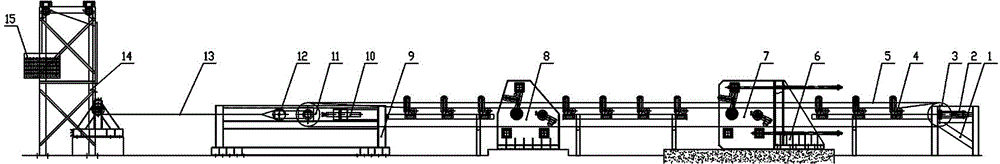

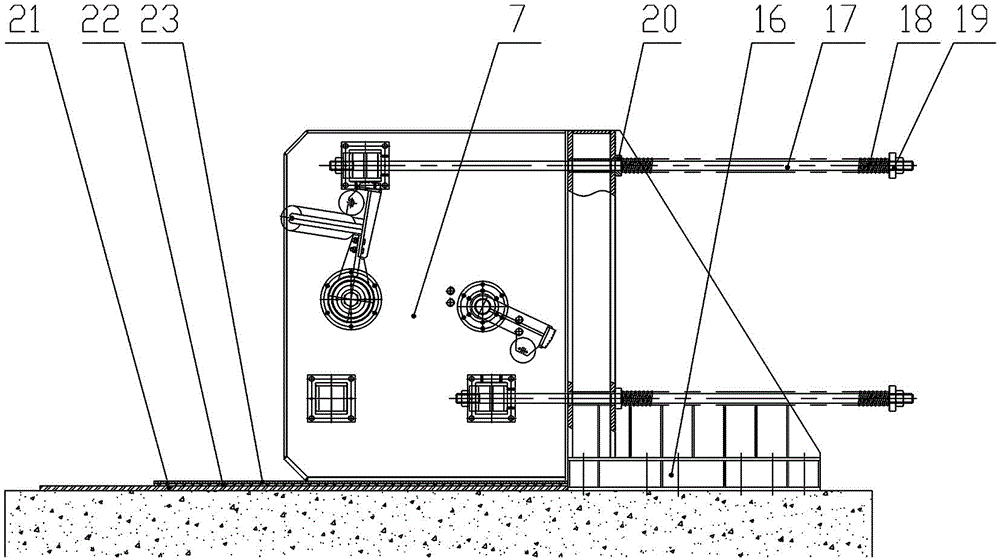

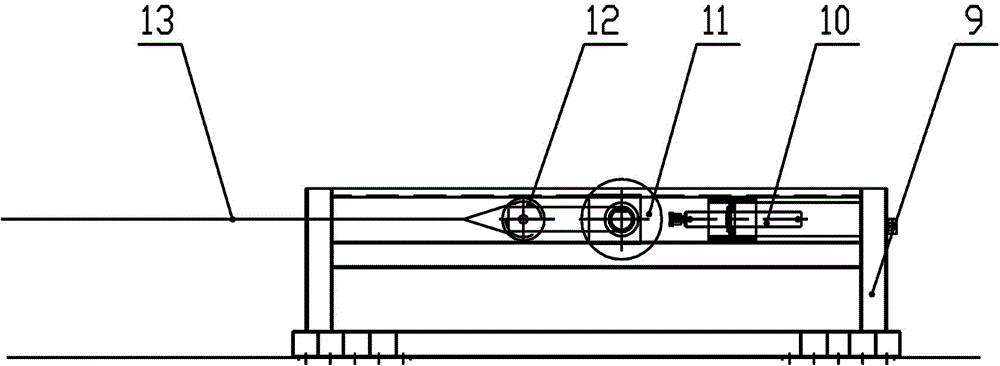

[0013] The comprehensive performance safety test system of the broken belt arresting device with the buffer device of the present invention, its preferred specific implementation is as follows figure 1 , figure 2 , image 3 , Figure 4 As shown, the comprehensive performance safety test system of the broken belt arresting device with a buffer device includes a tail frame 1, a hydraulic push cylinder 2, a tail drum 3, an excessive idler group 4, a conveyor belt 5, a buffer device 6, a movable Broken belt catching device 7, fixed broken belt catching device 8, head frame 9, hydraulic automatic tensioning device 10, head drum 11, tensioning pulley 12, steel wire rope 13, support frame 14 and counterweight box 15.

[0014] The hydraulic push cylinder 2 is fixedly arranged on the tail frame 1, the tail roller 3 is fixedly arranged on the tail frame 1, the buffer device 6 includes a base 16, a connecting shaft 17 and a spring 18, and the base 16 is fixedly arranged on the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com