Transformer Temperature Measuring Resistance Device and Its Protective Cover

A temperature measuring resistance and transformer technology, which is applied to transformer/inductor parts, measuring devices, electrical devices, etc., can solve the problems of reducing the safe operation coefficient of the transformer, and achieve a simple and ingenious structure, convenient installation, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

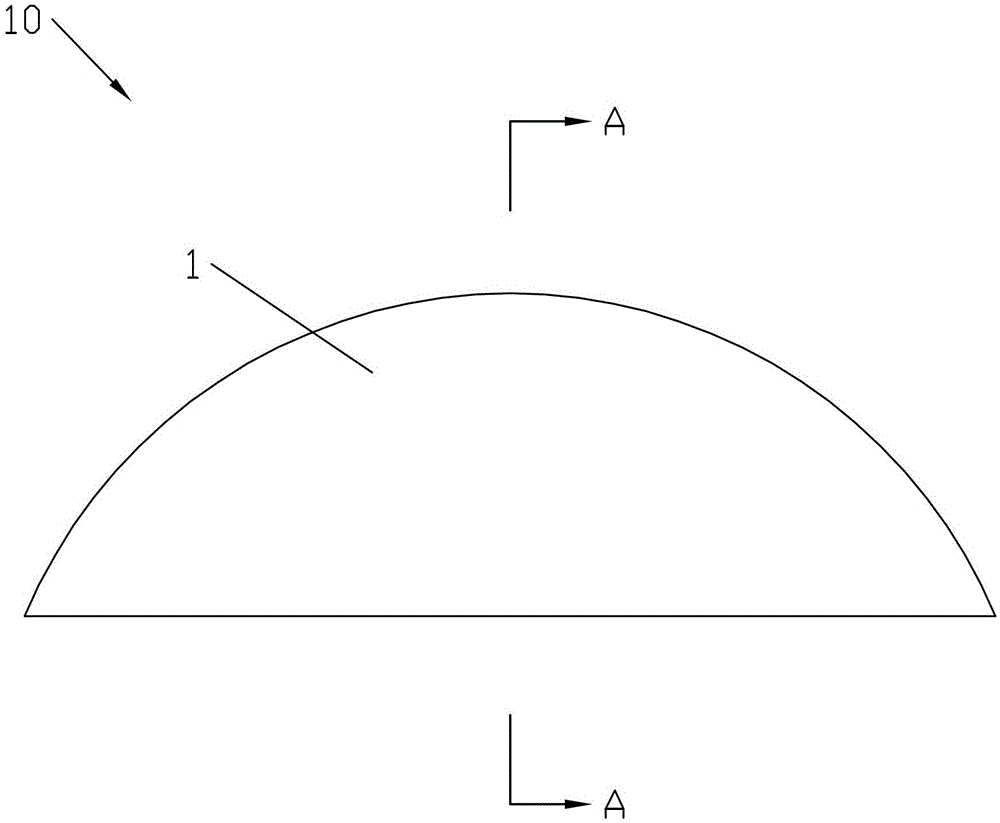

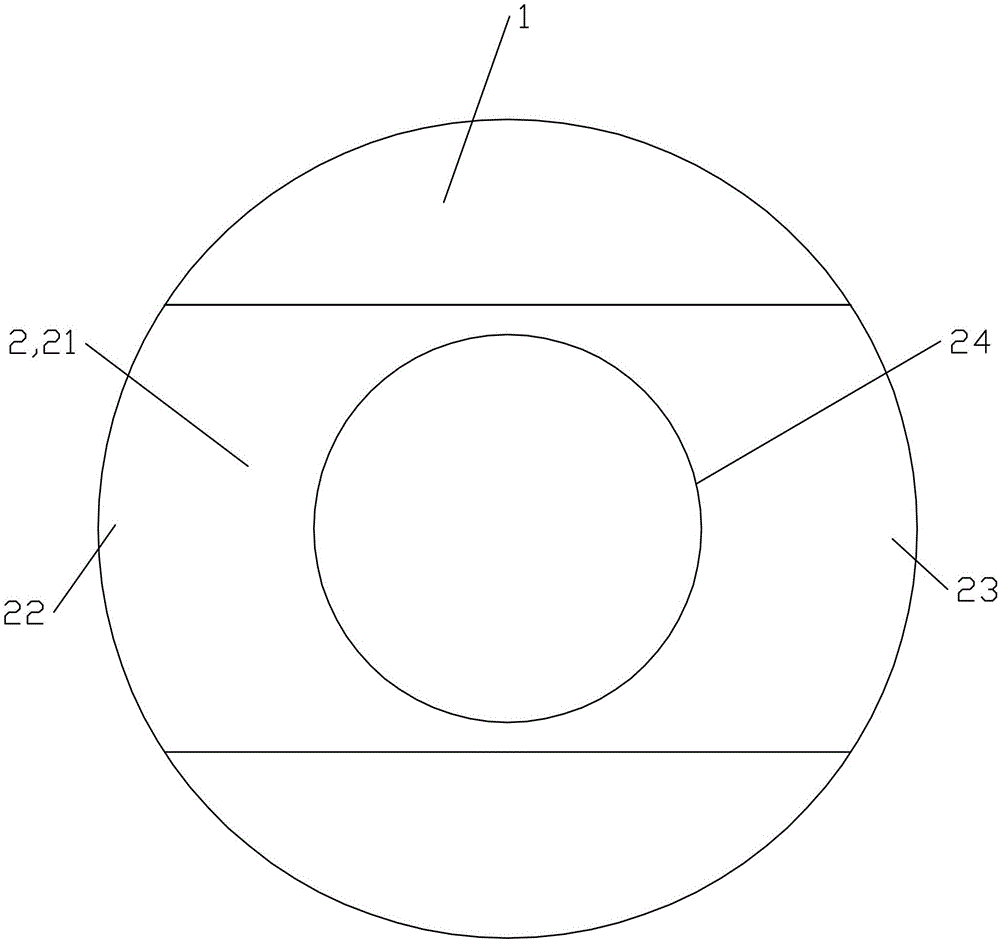

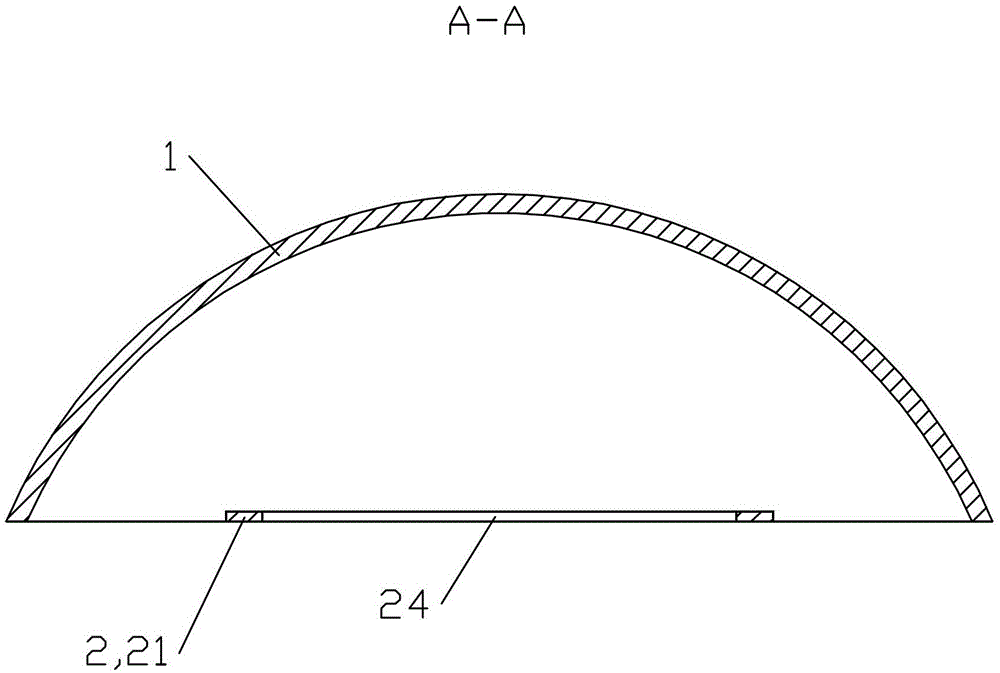

[0039] (Example 1, the protective cover of the transformer temperature measuring resistance device)

[0040] See Figure 1 to Figure 3The protective cover of the transformer temperature measuring resistance device in this embodiment includes a housing 1 and a mounting piece 2 connected to the housing 1; The shell 1 is a spherical crown with an opening downwards, and is made of stainless steel. The mounting piece 2 is arranged horizontally along the left and right directions, and is made of stainless steel plate material, including a rectangular plate portion 21, a first arcuate plate portion 22 connected to the left side of the rectangular plate portion 21 from the left, and a first arcuate plate portion 22 connected to the rectangular plate portion 21 from the right. The second arcuate plate portion 23 on the right side. The rectangular plate portion 21 is provided with a mounting through hole 24 along the vertical axis of the central axis, and the vertical axis of the moun...

Embodiment 2

[0041] (Example 2, transformer temperature measuring resistance device)

[0042] See Figure 4 , The transformer temperature-measuring resistance device of this embodiment includes a transformer casing 3, a temperature-measuring resistance 4, a rubber sealing ring 5, and the protective cover 10 (hereinafter referred to as the protective cover) of the transformer temperature-measuring resistance device obtained in Example 1.

[0043] The transformer shell 3 is provided with a shell main body 30, a temperature measuring resistance mounting pile 31 and a temperature measuring box 32; the shell body 30 of the transformer shell 3 is provided with a circular temperature measuring port with an upward opening, and the temperature measuring resistance mounting pile 31 is up and down. It is cylindrical in shape, and the central through hole of the temperature measuring resistance mounting pile 31 is an inner screw hole. The temperature measuring resistance mounting pile 31 is sealed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com