Anti-jump milling operation method of coal mill lubricating station double-pump operation

An operation method and a thin oil station technology, applied in mechanical equipment, grain processing, fluid pressure actuation devices, etc., can solve the problems of non-disappearing DCS feedback of jumping pumps, pressure chains, unreliable electrical protection, etc., to improve safe operation coefficient, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

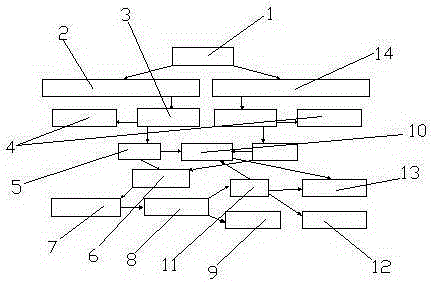

[0020] refer to figure 1 As shown, the operation method of double-pump operation of coal mill thin oil station to prevent skipping grinding includes the following steps:

[0021] 1) DCS gas station start command 1;

[0022] 2) The oil pump in the control cabinet selects the first oil pump to work, and the second oil pump is standby 2;

[0023] 3) The first oil pump contactor excitation 3, DCS oil pump operation feedback 4;

[0024] 4) The first oil pump runs 5;

[0025] 5) The oil pressure of the system is abnormal 6;

[0026] 6) The second oil pump of the hydraulic joint starts to run 7;

[0027] 7) DCS double pump operation alarm 8, switch the forced start switch 9;

[0028] 8) Eliminate the fault 11, the system oil pressure is normal 10, and the forced switch is released 12;

[0029] 9) The system is running normally13.

[0030] In the step 2) the control cabinet can also control the second oil pump to work, and the first oil pump is in standby 14 .

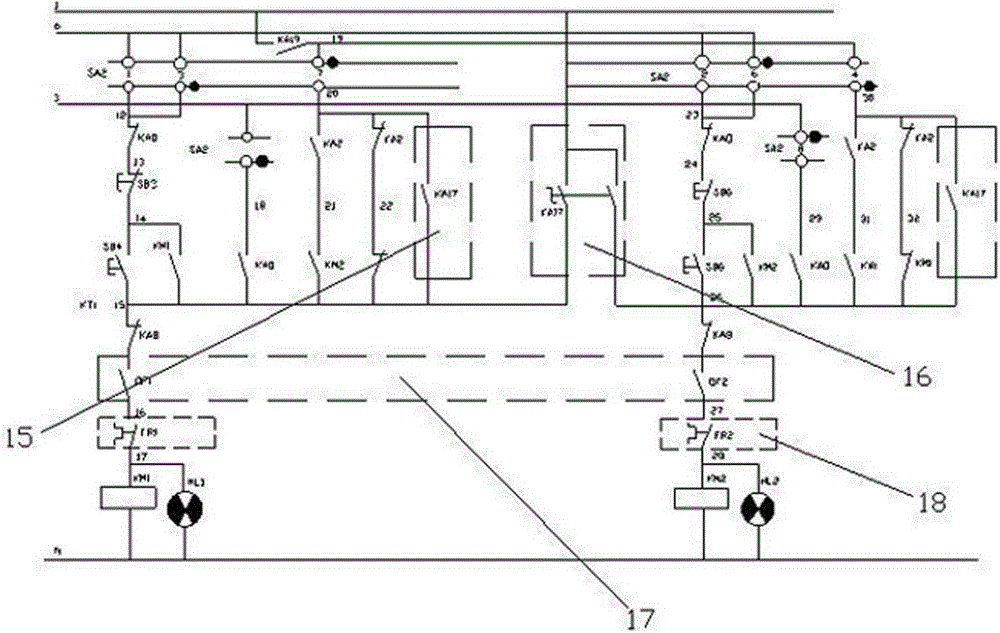

[0031] refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com