Fluorophosphate glass, precision press molding preform, optical element blank, optical element and method of manufacturing the same

A fluorophosphoric acid glass, optical element technology, applied in optical elements, glass pressing, glass manufacturing equipment, etc., to achieve the effect of excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0183] Hereinafter, the present invention will be described in further detail through examples, but the present invention is not limited by these examples at all.

Embodiment 1

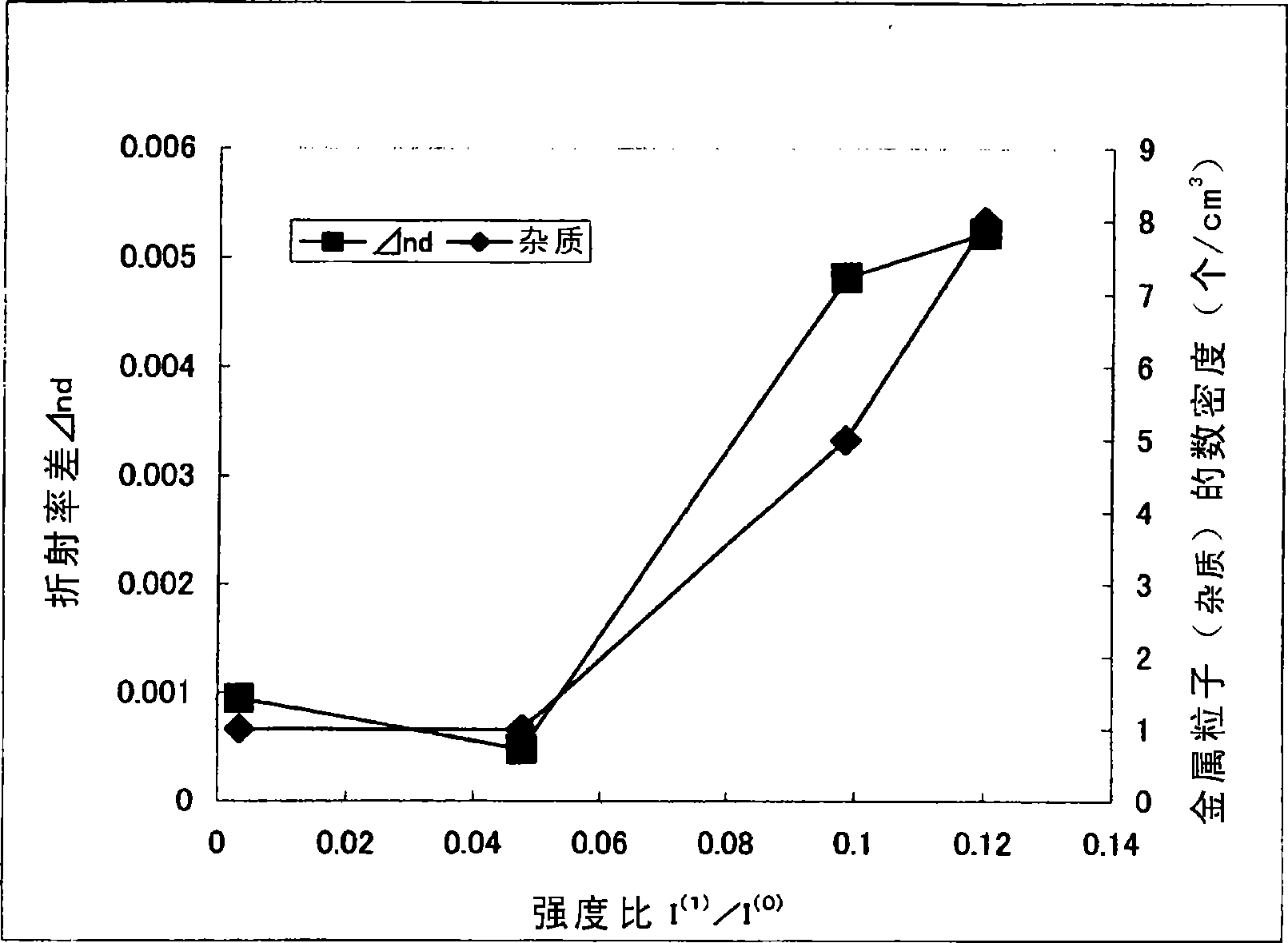

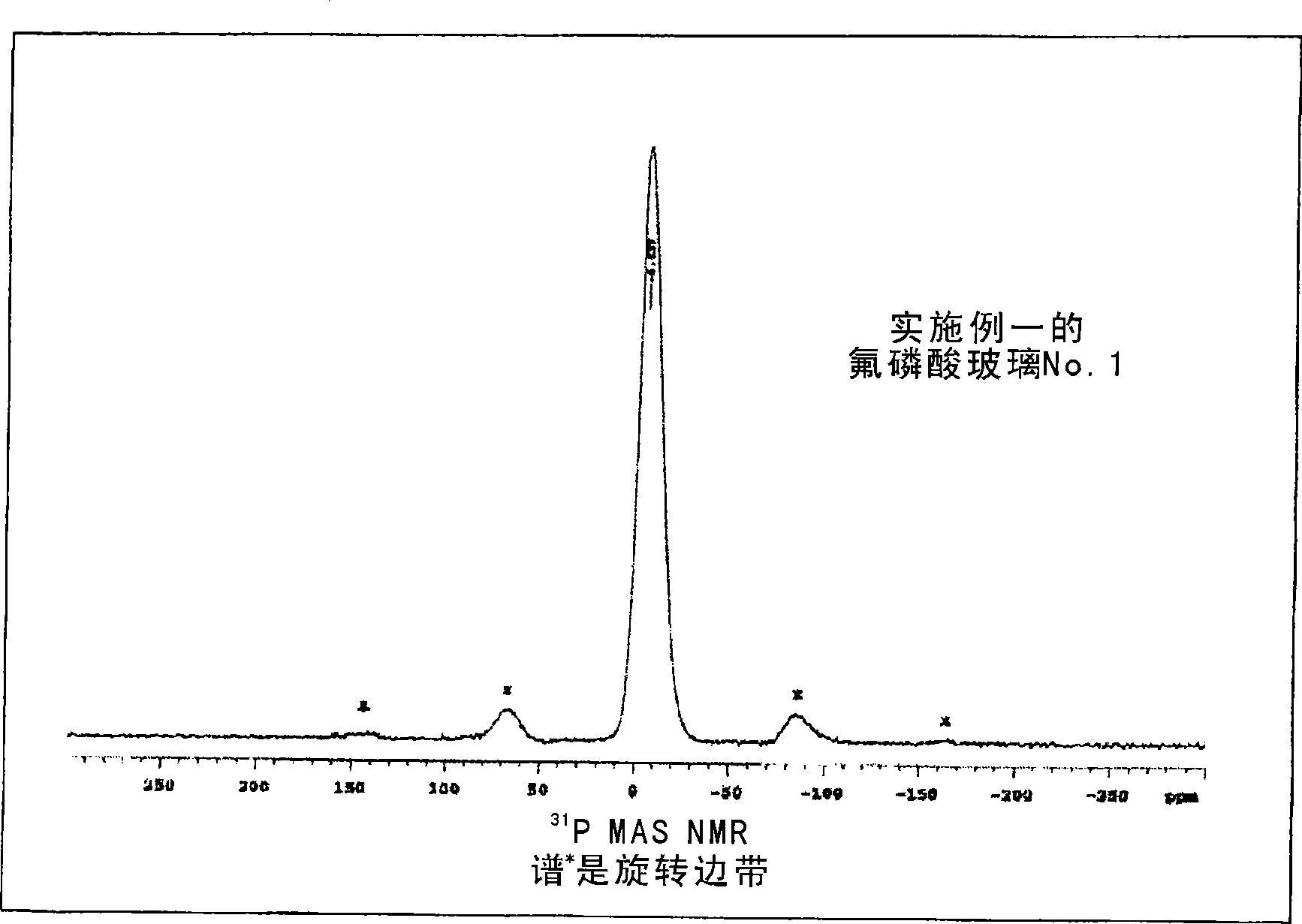

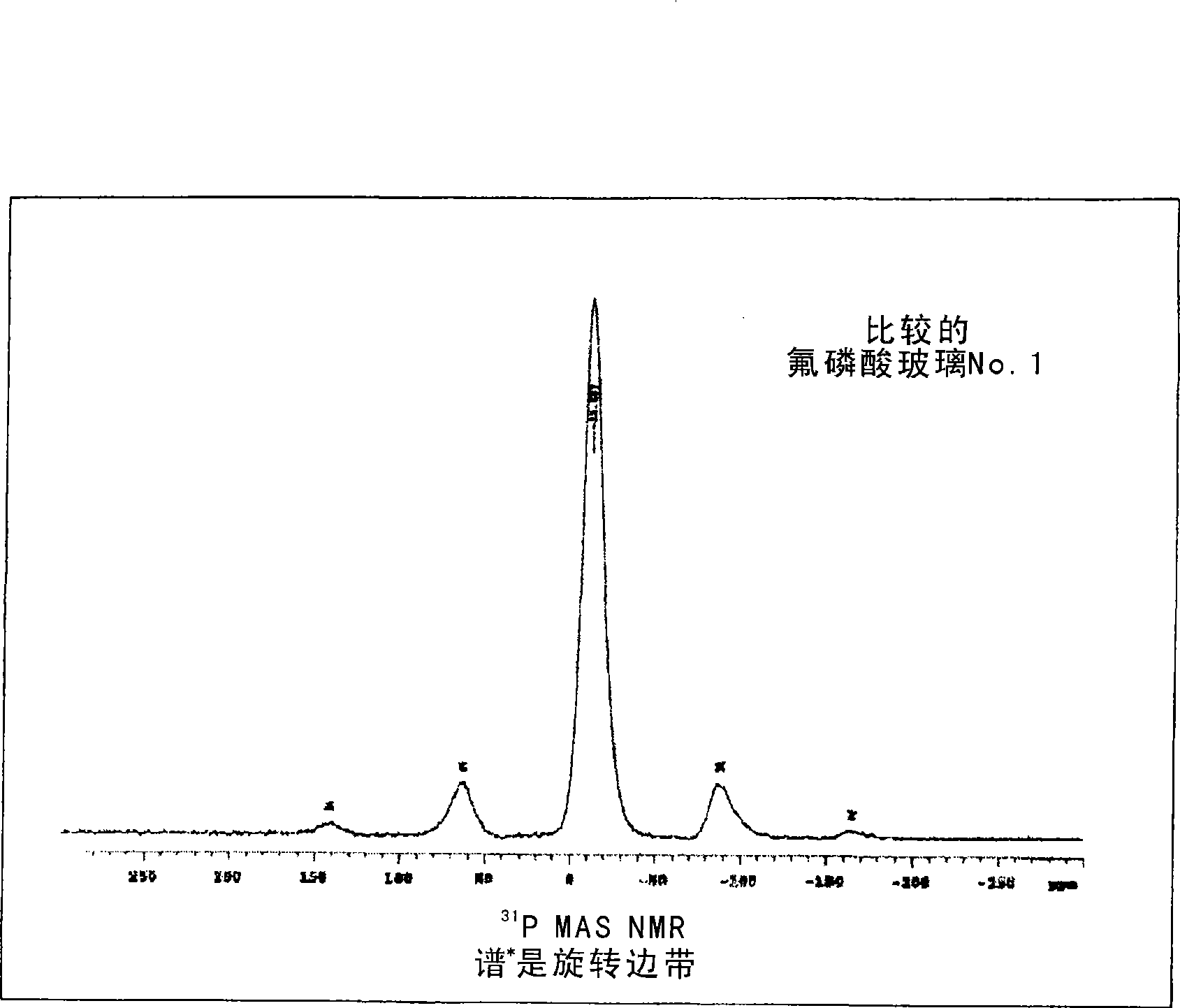

[0184] Example 1 and Comparative Example 1 (Manufacturing Example of Fluorophosphate Glass)

[0185] In order to manufacture fluorophosphoric acid glass Nos. 1 to 17 and comparative fluorophosphoric acid glass Nos. 1 and 2 having the compositions shown in Table 1-1 to Table 1-5, weigh the diphosphate corresponding to each glass composition. and other raw materials such as phosphate and fluoride, and thoroughly mix them. O in each mixed raw material 2- The total content and P 5+ The ratio of the total content (O 2- / P 5+ ), the total content of alkaline earth metal components and the total content of rare earth components are described in Table 1-1 to Table 1-5 together with the composition and characteristics of each glass. The above-mentioned mixed raw materials were put into a platinum crucible, stirred in an electric furnace at 900°C, heated and melted for 1 to 3 hours, clarified and homogenized, thereby obtaining fluorophosphate glass Nos. 1 to 17.

[0186] In the man...

Embodiment 2

[0221] Example 2 (Manufacturing Example of Preform for Precision Compression Molding)

[0222] The lump of molten glass was separated by a method in which the molten glass formed from each of the fluorophosphate glasses No. 1 to 17 shown in Table 1-1 to Table 1-5 was not devitrified in the glass. In some cases, the molten glass flows out at a certain flow rate from a platinum alloy pipe whose temperature is adjusted to a temperature range where it can flow out stably, and the glass block drops; or after the support body is used to support the top of the molten glass flow, the support body is suddenly lowered and separated. glass block. Each obtained molten-glass gob has the weight which added the weight of the removal part mentioned later to the weight of one target preform.

[0223] Next, each of the obtained molten glass gobs was received in a support mold having a gas ejection port at the bottom, and gas was ejected from the gas ejection port to float the glass gobs while ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com