Stemming utilizing waste refractory material and preparation method thereof

A technology of waste refractory materials and gun mud, which is applied in the direction of improving process efficiency, etc., can solve the problems of discarding or burying, occupying land resources, and the failure of comprehensive utilization of waste electric furnace lining materials, so as to reduce the iron infiltration rate and save energy. Environmental protection, effect of reducing cracking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

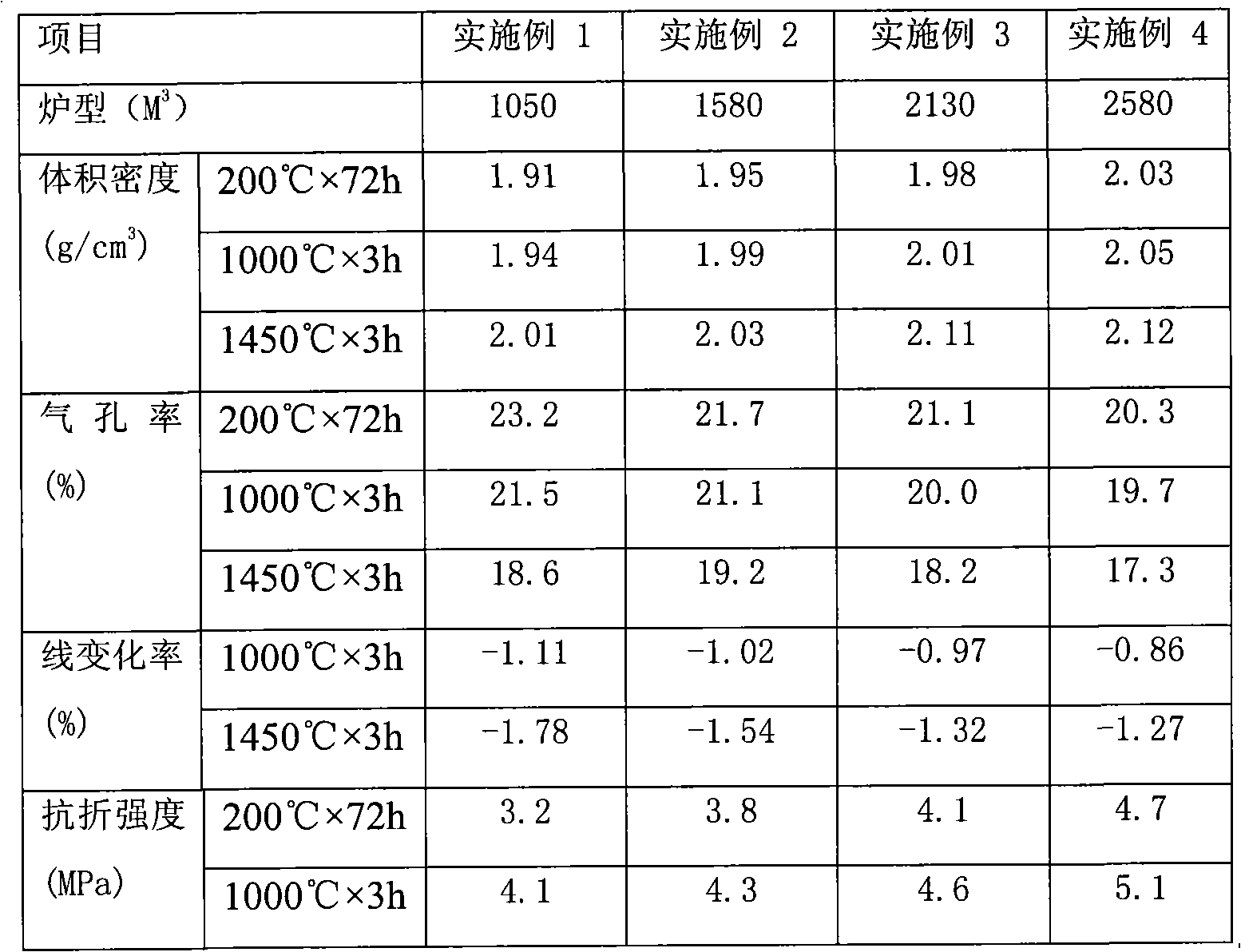

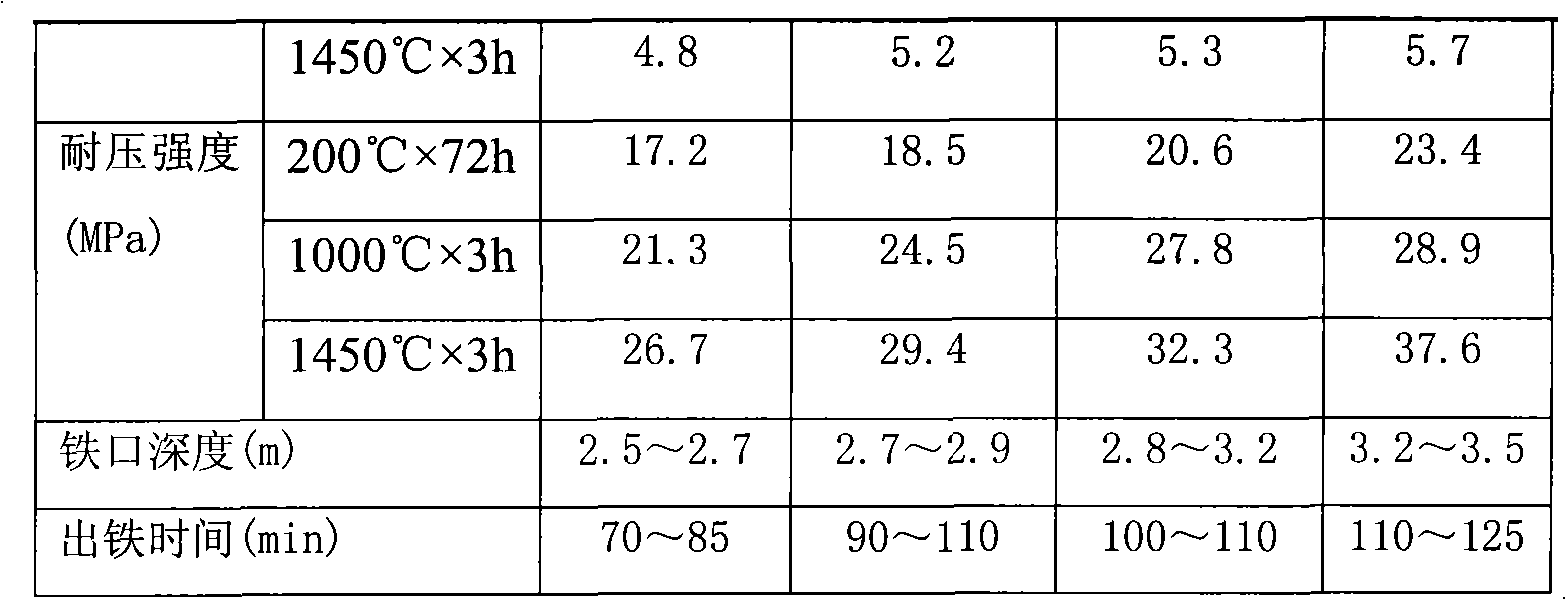

Embodiment 1

[0012] The batching of gun mud adopts silicon carbide fine powder (≤0.088mm) to account for 10% of the batching quality; high-temperature asphalt fine powder (≤0.1mm) accounts for 5% of the batching quality; Jilin clay fine powder (≤0.073mm) accounts for 20% of the batching quality %; coke particles (≤3mm) account for 25% of the batching quality; industrial grade corundum fine powder (≤0.073mm) account for 10% of the batching quality; recycled electric furnace magnesium aluminum material particles (≤3mm) account for 10% of the batching quality, Recycled electric furnace magnesium-aluminum material particles (≤1mm) account for 10% of the batching mass, and recycled electric furnace magnesium-aluminum material fine powder (≤0.088mm) accounts for 10% of the batching mass. The amount of tar added is added, accounting for 20% of the total mass of the ingredients.

Embodiment 2

[0014] The batching of gun mud adopts silicon carbide fine powder (≤0.088mm) accounting for 15% of the batching quality; high-temperature asphalt fine powder (≤0.1mm) accounts for 5% of the batching quality; Jilin clay fine powder (≤0.073mm) accounts for 15% of the batching quality %; coke particles (≤3mm) account for 25% of the batching quality; industrial grade corundum fine powder (≤0.073mm) account for 15% of the batching quality; recovery of electric furnace magnesium aluminum material particles (≤3mm) account for 10% of the batching quality, Recycled electric furnace magnesium-aluminum material particles (≤1mm) account for 15% of the batching mass. Tar addition is extra, accounts for 18% of batching gross mass.

Embodiment 3

[0016] Silicon carbide fine powder (≤0.088mm) accounts for 20% of the batching quality; high-temperature asphalt fine powder (≤0.1mm) accounts for 5% of the batching quality; Jilin clay fine powder (≤0.073mm) accounts for 15% of the batching quality. %; coke particles (≤3mm) account for 20% of the batching quality; industrial grade corundum fine powder (≤0.073mm) account for 20% of the batching quality; recovery of electric furnace magnesium aluminum material particles (≤3mm) account for 10% of the batching quality, Recycled electric furnace magnesium-aluminum material particles (≤1mm) account for 10% of the batching mass. Tar addition is extra, accounts for 17% of batching gross mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com