Fluorophoshoric acid glass, die pressing forming glass material, optical element blank, optical element and manufacturing method thereof

A fluorophosphoric acid glass, a technology for a manufacturing method, and applied in the directions of optical components, glass pressing, glass manufacturing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0267] Example 1 (manufacturing example of fluorophosphate glass)

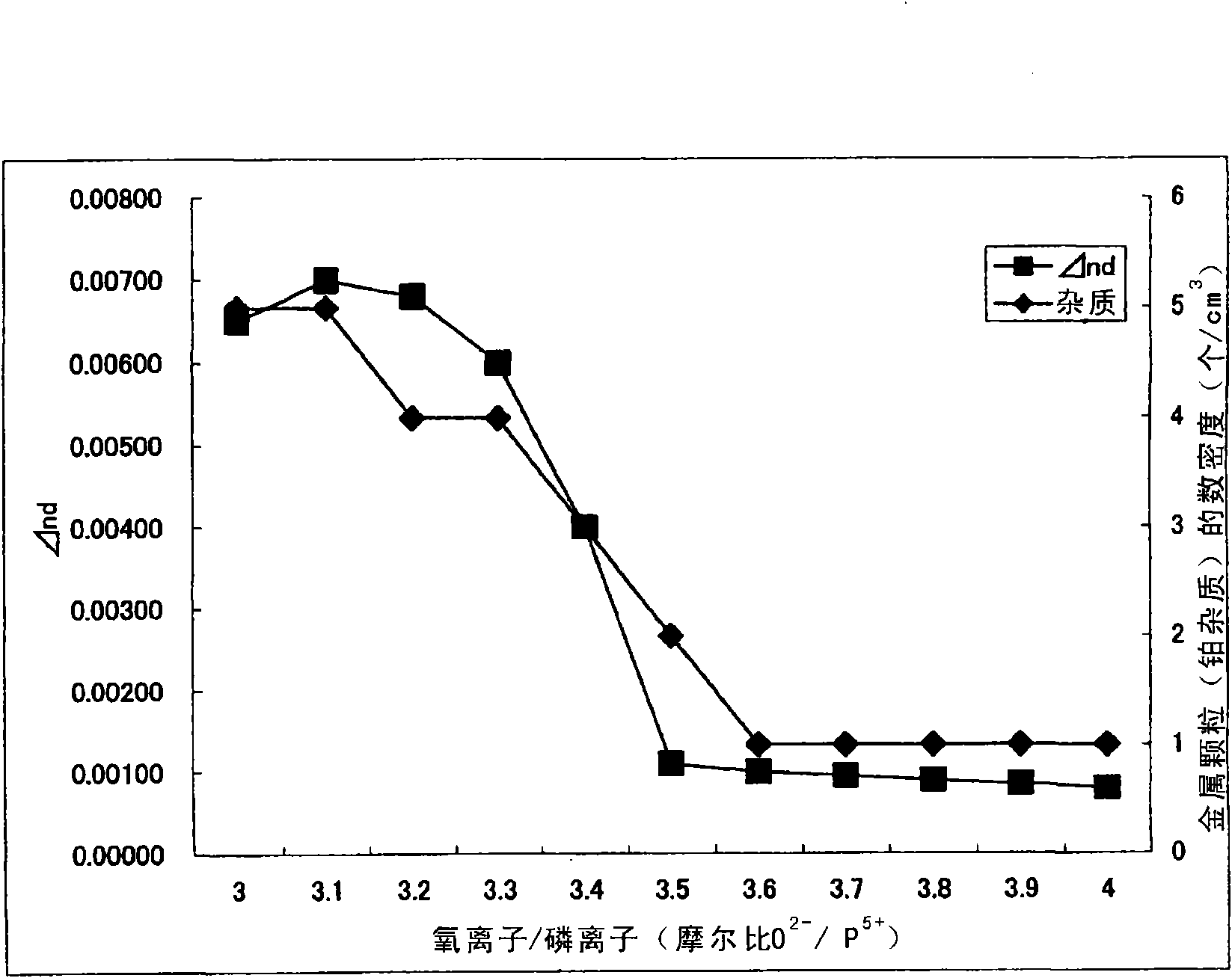

[0268] In order to produce glass having each composition shown in Tables 1-1 to 1-6, raw materials such as phosphate such as bisphosphate and fluoride corresponding to each glass component are weighed and thoroughly mixed. The O in the glass raw material 2- The total content of P 5+ The ratio of the total content O 2- / P 5+ , F - The content of F - And O 2- Ratio of total content (F - / (F - +O 2- )) are listed in Tables 1-1 to 1-6. Put the above mixed raw materials into a platinum crucible, heat and melt the raw materials for 1 to 3 hours while stirring in an electric furnace at 900°C, clarify and homogenize, and then pour the resulting molten glass into a mold , Obtained bulk glass formed from various fluorophosphate glasses of 1-59 fluorophosphate glasses. During the melting, clarification, and homogenization of the glass, the atmosphere is not exchanged.

[0269] No texture was found in any of the fluorophospha...

Embodiment 2

[0298] Example 2 (manufacturing example of a preform for press molding)

[0299] The molten glass from which the fluorophosphate glasses 1 to 59 can be obtained is separated into the molten glass mass by the following method, namely: from a platinum alloy made of a temperature range where the temperature can be adjusted to stably flow out of the glass without devitrifying the glass The method in which the molten glass flows out of the pipe at a certain flow rate and drops the glass block; or the method of using a support body to support the front end of the molten glass flow and then suddenly lowering the support body to separate the glass block. Each obtained molten glass block has a weight obtained by adding the weight of the removed part described later to the weight of one target preform.

[0300] Next, each of the obtained molten glass lumps is connected to a receiving mold having a gas ejection port at the bottom, and gas is injected from the gas ejection port to float the g...

Embodiment 3

[0305] Example 3 (manufacturing example of optical element)

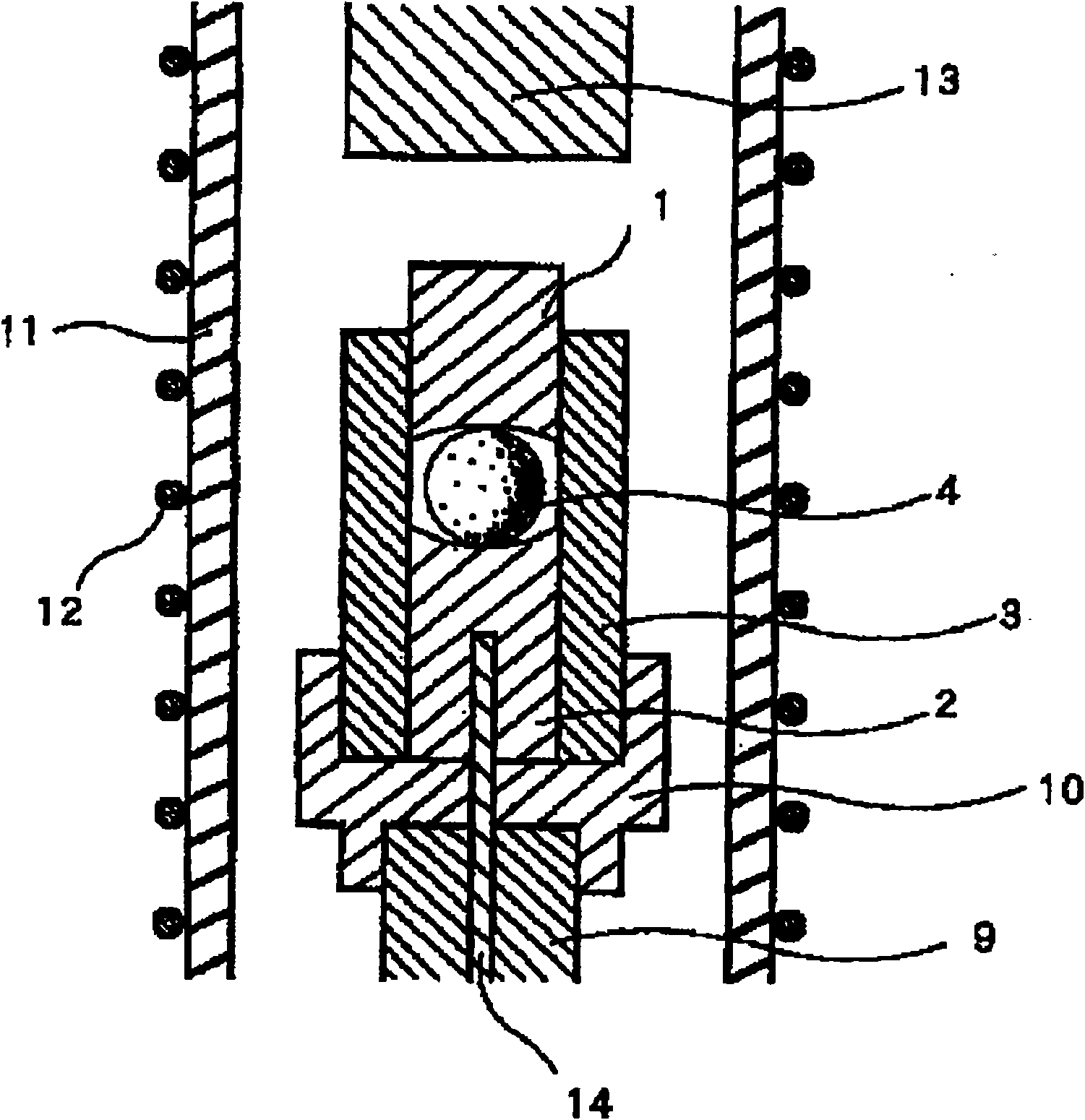

[0306] use figure 2 The shown press molding apparatus performed precision press molding of the preforms formed of each of the fluorophosphate glasses 1 to 59 obtained in Example 2 to obtain an aspherical lens.

[0307] That is, after the preform 4 is set between the lower mold 2 and the upper mold 1 of the compression molding mold composed of the upper mold 1, the lower mold 2 and the body mold 3, the quartz tube 11 is set in a nitrogen atmosphere, and The heater 12 is energized to heat the inside of the quartz tube 11. Set the temperature inside the press forming mold so that the glass to be formed shows 10 8 ~10 10 The temperature of the viscosity of dPa·s, and while maintaining the temperature, the lowering plunger 13 presses the upper mold 1 to press the preform placed in the forming mold. The pressing pressure is 8 MPa, and the molding time is 30 seconds. After the molding, the pressure of the molding is released, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com