Device for testing electrical erosion property of electrical contact material

A technology for electric contact materials and testing devices, which is applied in the direction of measuring devices, analysis materials, instruments, etc., and can solve the problems of inability to detect the displacement of electric contacts and the lack of synchronous control functions of electric contacts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

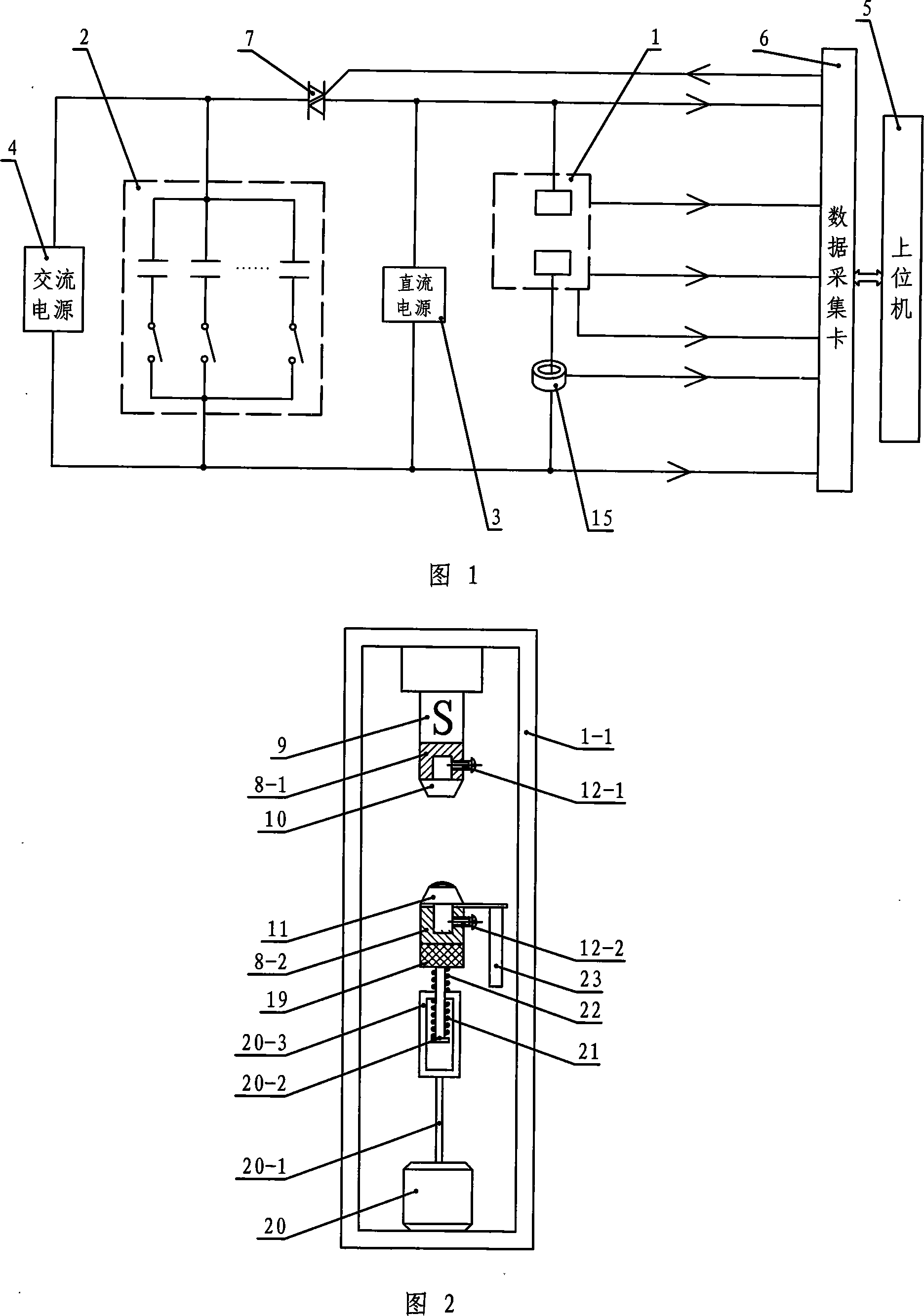

[0007] Specific embodiment 1: Referring to Fig. 1 and Fig. 2, this embodiment consists of an electric contact mechanical movement operation test device 1, a low-voltage constant current power supply 3, an AC power supply 4, a host computer 5 and a thyristor switch 7, which can be controlled The anode of the silicon switch 7 is connected to the first power supply terminal of the AC power supply 4, the cathode of the silicon controlled switch 7 is connected to the first power supply terminal of the electrical contact mechanical movement operation test device 1, and the second power supply terminal of the AC power supply 4 is connected to the electric contactor. The second power supply end of the contact mechanical movement operation test device 1 is connected, the control signal input end of the thyristor switch 7 is connected with the control signal output end of the data acquisition card 6, and the positive end of the low voltage constant current power supply 3 is connected with...

specific Embodiment approach 2

[0009] Specific embodiment 2: Referring to Fig. 1, this embodiment adds a capacitor bank 2 on the basis of specific embodiment 1, the first power supply end of the capacitor bank 2 is connected to the anode of the thyristor switch 7, and the second terminal of the capacitor bank 2 The power terminal is connected to the second power terminal of the electrical contact mechanical movement operation testing device 1 . When the AC power supply 4 adopts an ordinary AC system, it has the advantages of simplicity and directness, good waveform conditions of the power supply, and convenient voltage adjustment; the disadvantage is that the electrical capacity of the laboratory under general conditions is limited, and its experimental current level is mostly less than 100A. , and frequent on and off operations will cause serious interference to other electrical equipment in the circuit, especially electronic instruments and computer equipment, affect their service life, measurement accurac...

specific Embodiment approach 3

[0010] Specific embodiment three: Referring to Fig. 2, the difference between this embodiment and specific embodiment one or two is that the electrical contact mechanical movement operation test device 1 includes a static contact base 8-1, a moving contact base 8-2, Force measuring device 9, static contact 10, moving contact 11, electromagnetic exciter 20, ejector rod 20-1, inverted T-shaped transmission rod 20-2, rectangular frame 20-3, displacement measuring sensor 23, force measuring device 9 is arranged on the upper end surface of the inner side wall of the outer casing 1-1 of the electrical contact mechanical movement operation test device, and the welding force signal output end of the force measuring device 9 is connected with the welding force signal input end of the data acquisition card 6, statically The contact base 8-1 is set on the lower end surface of the force measuring device 9, the static contact 10 is set on the static contact base 8-1, the power end of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com