Composite slag weir and preparation method thereof

A slag retaining weir and composite technology, which is applied in the field of slag retaining weir and its preparation, can solve the problem that the aluminum-magnesium slag retaining weir is not as cost-effective as the magnesium slag retaining weir, the aluminum-magnesium material pollutes molten steel, and the aluminum-magnesium material price Advanced problems, to achieve the effect of reducing production costs, synchronizing service life, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

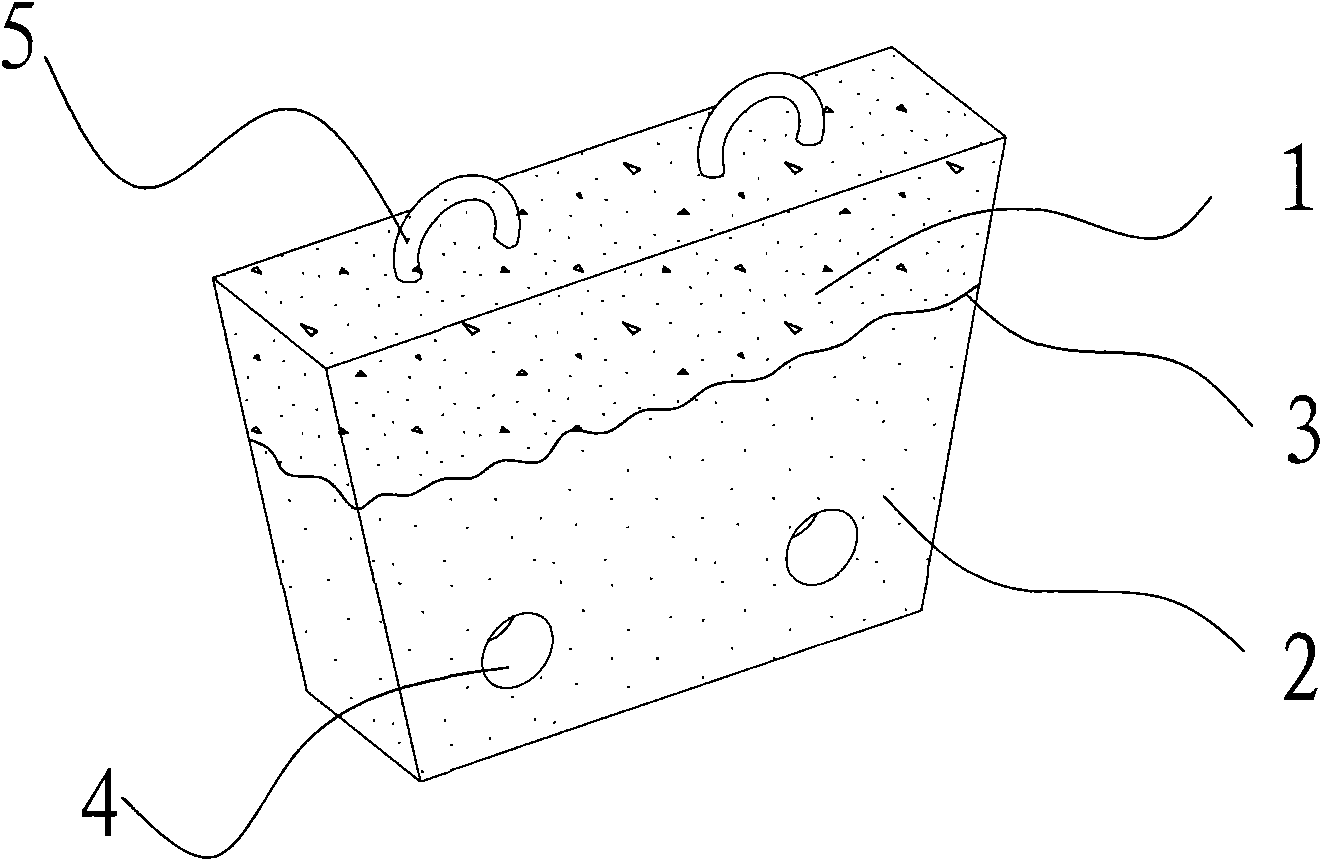

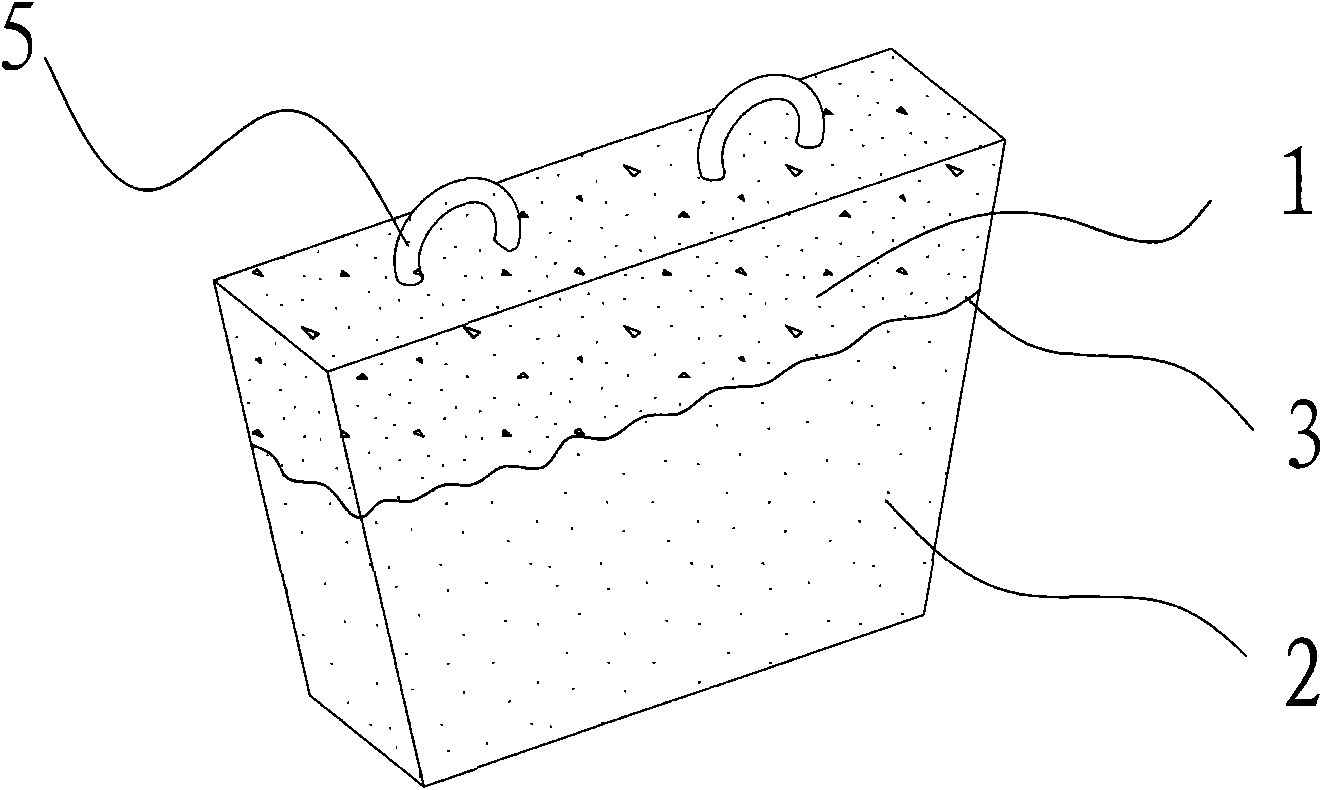

[0026] Example 1, a composite slag retaining weir, the molten steel retaining part 2 at the lower part of the weir body is made of magnesia material, and its specific composition and composition ratio by weight percentage are: 85% fused magnesia, 8% silicon micropowder , alumina powder 6.48%, sodium tripolyphosphate 0.2%, organic polycarboxylate water reducer 0.15%, retarder 0.15%, organic explosion-proof fiber 0.02%; the slag retaining part 1 on the upper part of the weir is made of aluminum magnesium material Production, its specific composition and composition ratio by weight percentage are: bauxite 44%, fused magnesia 25%, silicon micropowder 1%, alumina powder 8%, corundum powder 15%, magnesium aluminum spinel 6.73% , 0.2% sodium tripolyphosphate, 0.05% sodium hexametaphosphate, 0.02% organic explosion-proof fiber. The retarder is potassium sodium tartrate, and the organic anti-explosion fiber is polyurethane fiber.

[0027] The preparation method adopts horizontal compo...

Embodiment 2

[0030] Example 2, a composite slag retaining weir, the molten steel retaining part 2 at the lower part of the weir body is made of magnesia material, and its specific composition and composition ratio by weight percentage are: 90% fused magnesia, 5% silicon micropowder , alumina powder 4.48%, sodium tripolyphosphate 0.2%, organic polycarboxylate water reducer 0.15%, retarder 0.15%, organic explosion-proof fiber 0.02%; the slag retaining part 1 on the upper part of the weir is made of aluminum magnesium Production, its specific composition and composition ratio by weight percentage are: bauxite 47%, fused magnesia 20%, silicon micropowder 2%, alumina powder 5%, corundum powder 17.73%, magnesium aluminum spinel 8% , 0.2% sodium tripolyphosphate, 0.05% sodium hexametaphosphate, 0.02% organic explosion-proof fiber. The retarder is sodium citrate, and the organic anti-explosion fiber is polyurethane fiber.

[0031] The preparation method adopts the upper and lower composite method...

Embodiment 3

[0034] Example 3, a composite slag retaining weir, the molten steel part at the lower part of the weir body is made of magnesia material, and its specific components and proportions by weight percentage are: fused magnesia 95%, silicon micropowder 2%, Alumina powder 2.48%, sodium tripolyphosphate 0.2%, organic polycarboxylate water reducer 0.15%, retarder 0.15%, organic explosion-proof fiber 0.02%; Its specific components and proportions by weight percentage are: bauxite 50%, fused magnesia 15%, silicon micropowder 3%, alumina powder 2%, corundum powder 20%, magnesium aluminum spinel 9.73%, three Sodium polyphosphate 0.2%, sodium hexametaphosphate 0.05%, organic explosion-proof fiber 0.02%. Among them, the retarder is sodium oxalate, and the organic anti-explosion fiber is polyurethane fiber.

[0035] The preparation method is the same as in Example 2.

[0036] The product has been physically tested: the bulk density is 2.70g / cm 3 , The flexural strength is 9.11MPa, the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com