Testing device of high temperature erosiveness of electrodes for glass electric melting furnace and method thereof

A test device, glass electric technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of no test method, etc., achieve simple structure, high measurement accuracy, and improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

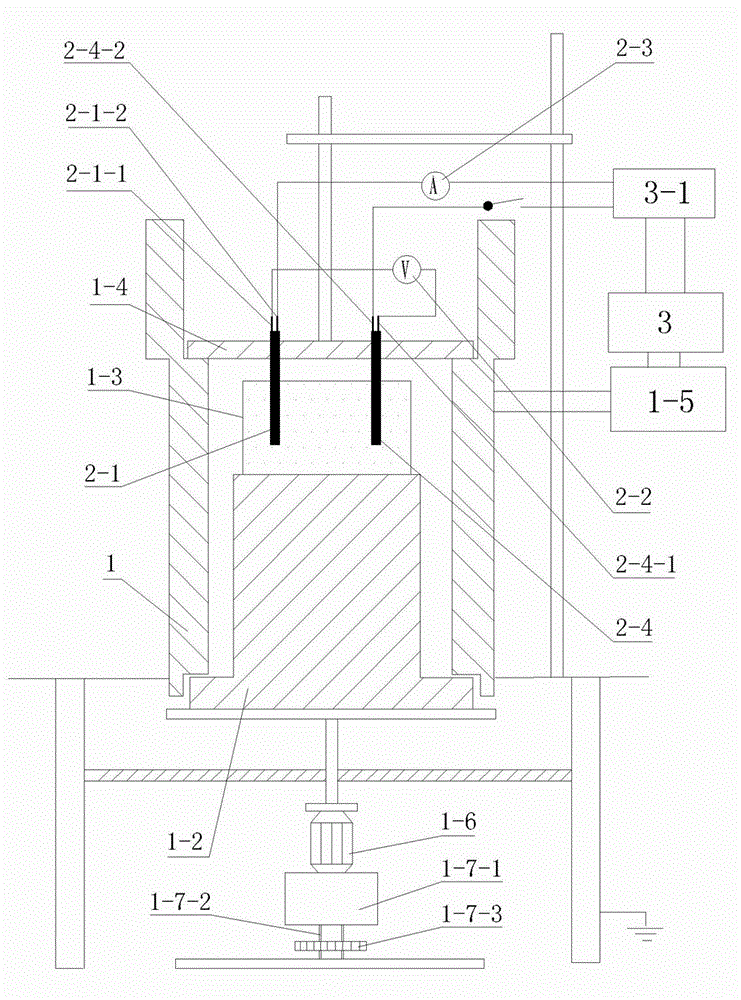

[0023] A test device for high-temperature erosion of electrodes used in glass electric melting furnaces. The structure includes a controllable preheating furnace 1. The key point is that the test device also includes a rotating base 1 that can be adjusted up and down in the preheating furnace 1. -2, the crucible 1-3 containing the molten glass, the two electrodes to be tested are connected to the output port of the power supply 3-1 by means of platinum terminals and wires positioned on the upper ends of the electrodes, and the two electrodes to be tested are positioned in the furnace Cover 1-4.

[0024] The degree of freedom of the rotating base 1-2 that can be lifted and adjusted is realized by means of a drive motor 1-6 and a lifting mechanism. For the handwheel 1-7-3 on the rotating lead screw 1-7-2, the driving motor 1-6 is arranged on the screw nut seat 1-7-1. Turn the handwheel 1-7-3, and the screw nut seat 1-7-1 driven by the rotating lead screw 1-7-2 drives the motor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com