Fluorophosphate glass, precision press molding preform, optical element blank, optical element and methods of manufacturing the same

A technology of fluorophosphoric acid glass and optical components, which is applied in the direction of optical components, glass pressing, glass manufacturing equipment, etc., to achieve the effect of excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0187] Hereinafter, the present invention will be described in further detail through examples, but the present invention is not limited by these examples at all.

Embodiment 1

[0188] Example 1 and Comparative Example 1 (Manufacturing Example of Fluorophosphate Glass)

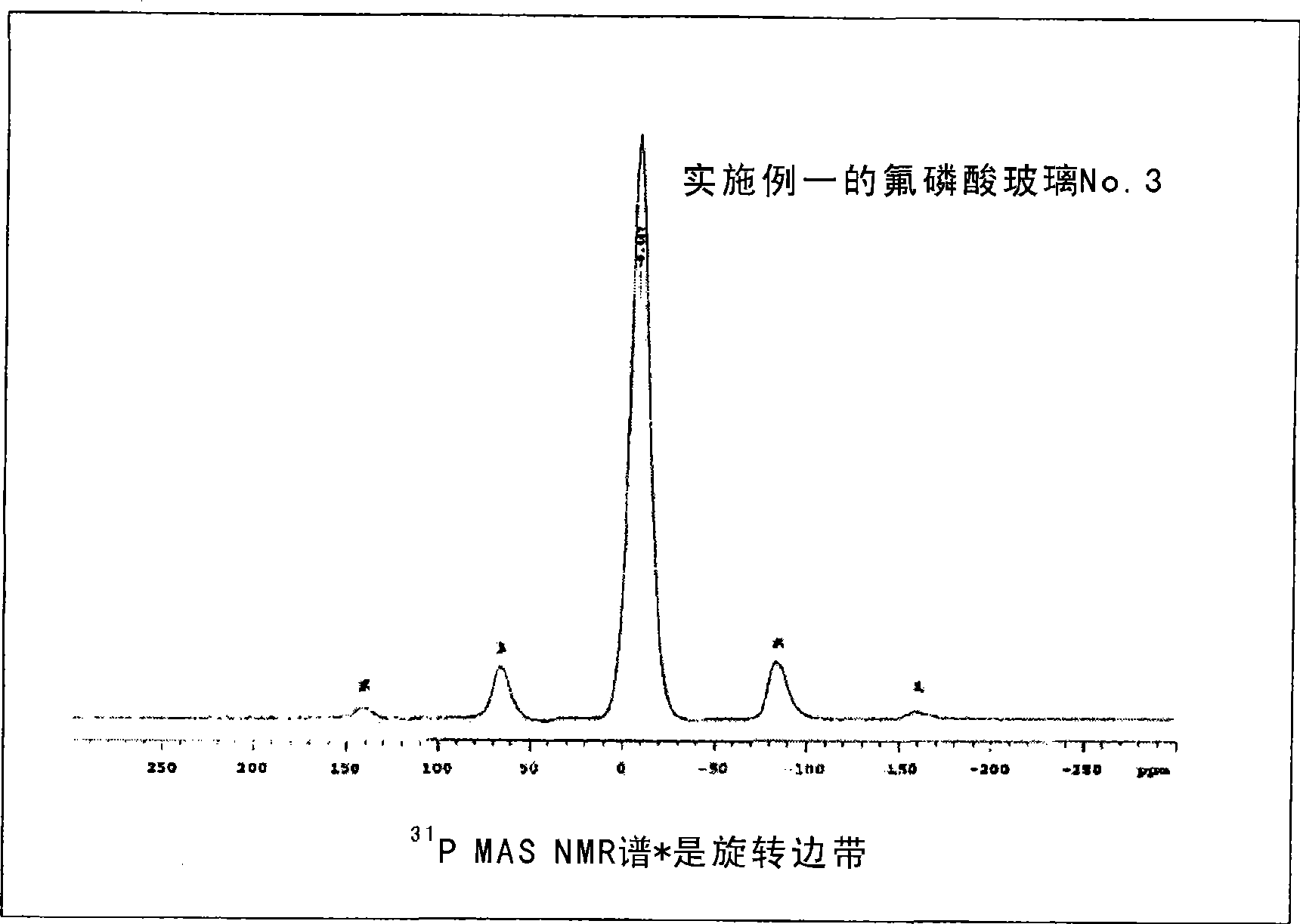

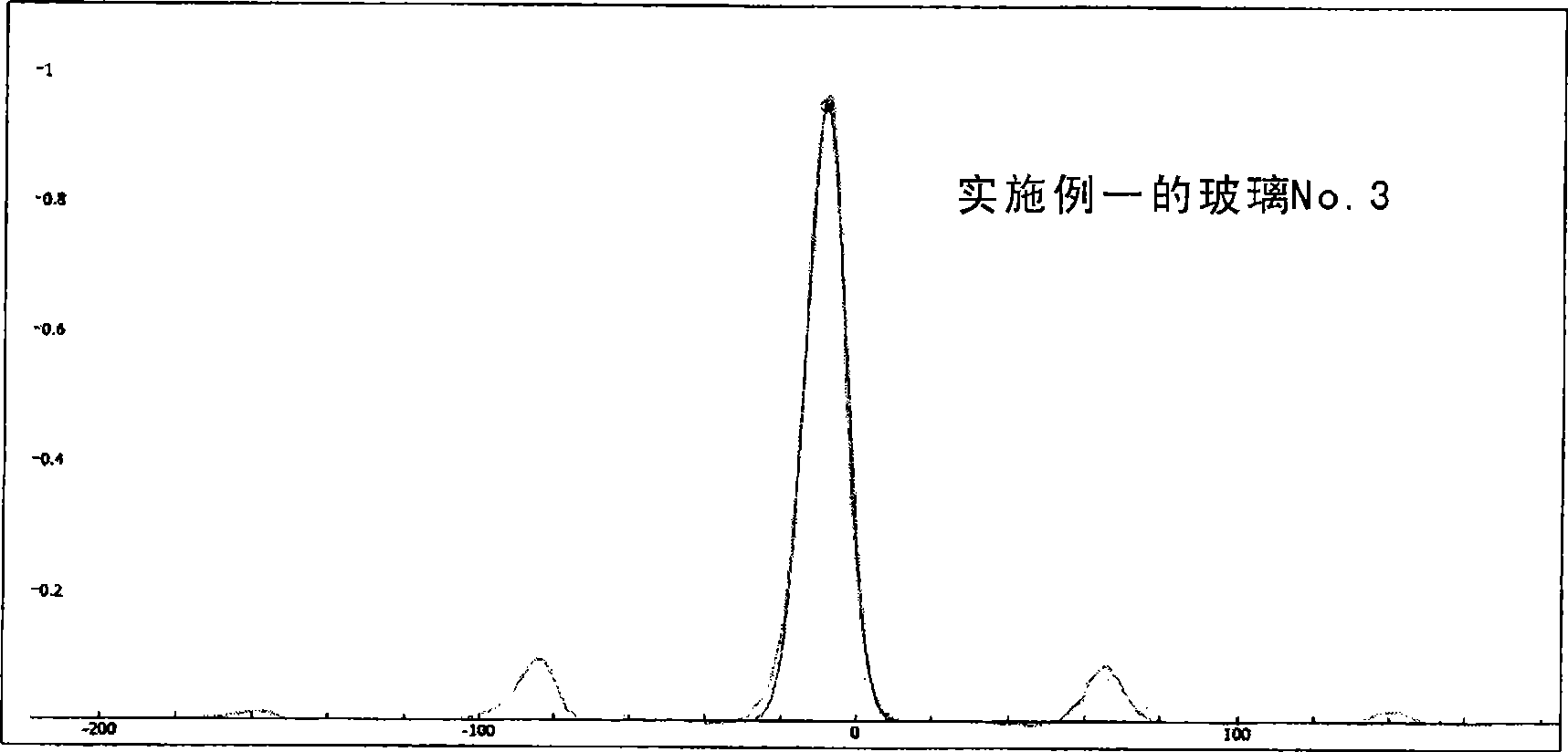

[0189] In order to manufacture fluorophosphate glasses No. 1 to No. 4 and comparative fluorophosphate glasses having the compositions shown in Table 1, raw materials such as phosphates such as diphosphates and fluorides corresponding to the respective glass components were weighed, and Mix well. O in each mixed raw material 2- The total content and P 5+ The ratio of the total content (O 2- / P 5+ ) and the content ratio of rare earth elements (cation %) are described together. The above-mentioned mixed raw materials were put into a platinum crucible, stirred in an electric furnace at 900° C., heated and melted for 1 to 3 hours, clarified and homogenized, thereby obtaining fluorophosphate glasses No. 1 to No. 4.

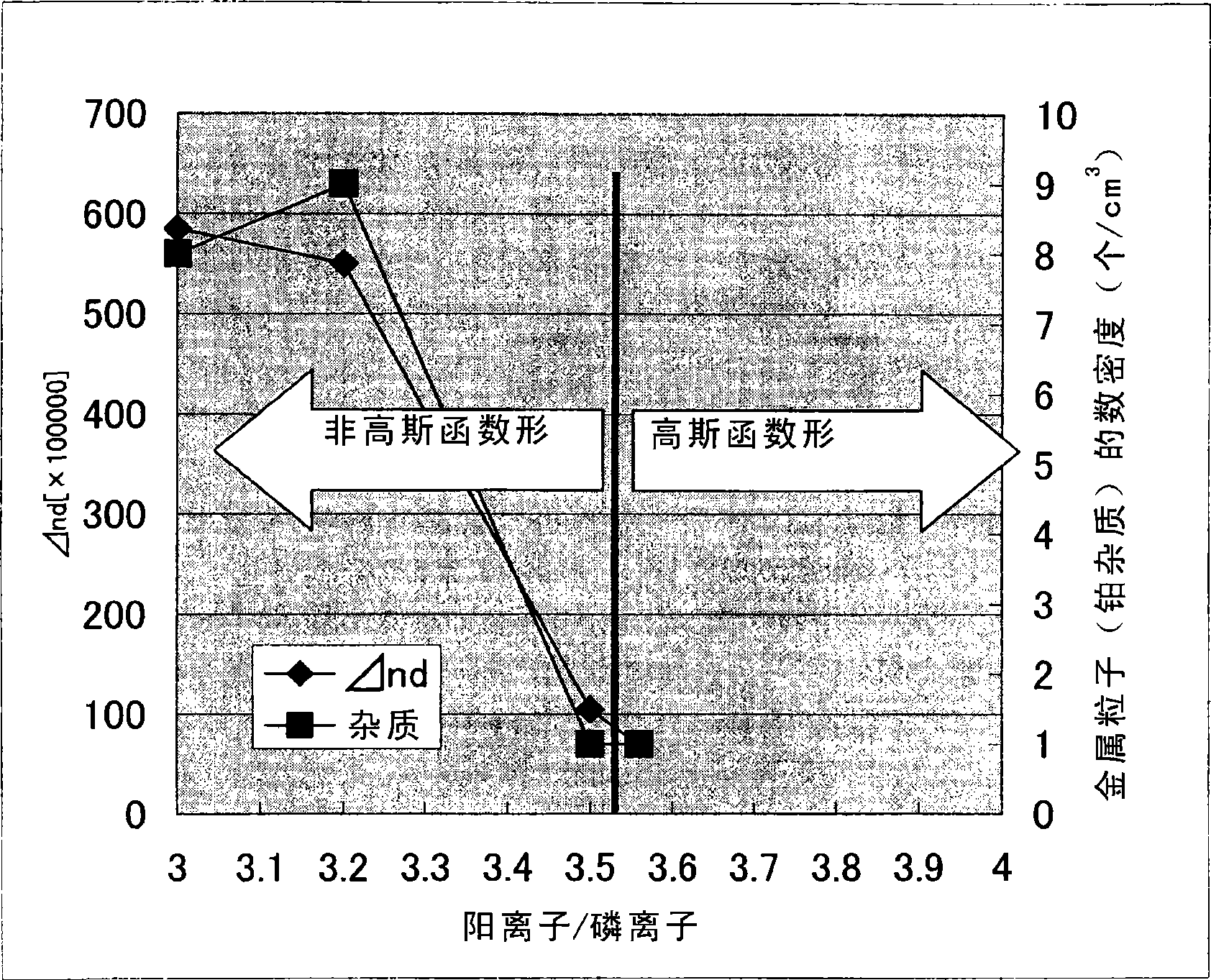

[0190] In the manufacture of each fluorophosphoric acid glass of fluorophosphoric acid glass No.1 to No.4, as shown in Table 1, O 2- The total content and P 5+ The rati...

Embodiment 2

[0209] Example 2 (Manufacturing Example of Preform for Precision Compression Molding)

[0210] The gob of molten glass was separated by a method in which the molten glass formed from each of the fluorophosphate glasses No. 1 to No. 4 shown in Table 1 was cooled from the temperature without devitrification of the glass. Flow out at a constant flow rate from a platinum alloy pipe adjusted to a temperature range capable of stably flowing out, and drop glass gobs; or use a support to support the tip of the flow of molten glass, then suddenly lower the support to separate the glass gobs. Each obtained molten-glass gob has the weight which added the weight of the removal part mentioned later to the weight of one target preform.

[0211] Next, each of the obtained molten glass gobs was received in a support mold having a gas ejection port at the bottom, and gas was ejected from the gas ejection port to float the glass gobs while forming them to produce a preform for precision press m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com