Equipment and process for modular treatment of oil field wastewater

A technology for treating equipment and oilfield wastewater, which is applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high cost, long treatment time, and large dosage of oxidant. Achieve the effect of reducing impact and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

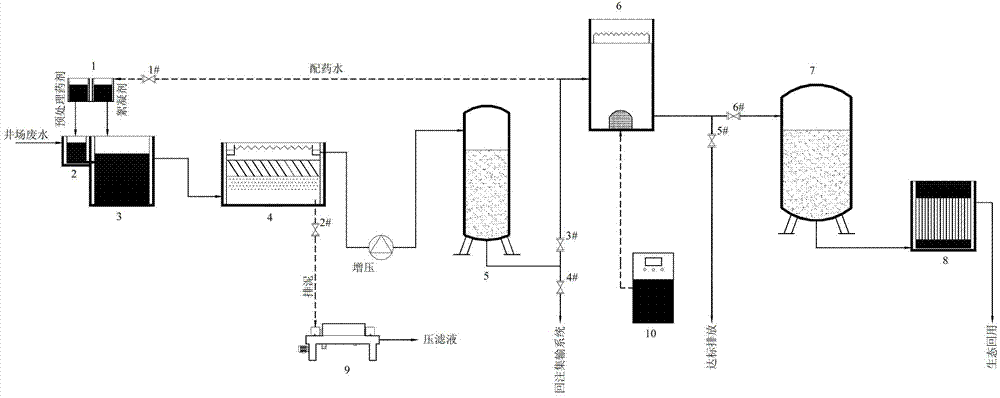

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0033] As shown in the figure, the present invention is a modular treatment equipment for oilfield wastewater, including a dosing system 1, which retains a pH regulator, pre-oxidant, flocculant, and coagulant dispensing box. When required by normal operation, the pretreatment agent is added to the pretreatment reaction tank 2 through the dosing system to complete the pretreatment of the wastewater; the pretreated wastewater enters the micro-interface control reactor 3 by itself, and is fed by the dosing system 1 The flocculant is mixed and reacted in the micro-interface control reactor 3 to complete micro-interface coagulation, decolorization, and oil removal; the treated water enters the inclined tube sedimentation tank 4 by itself, and the length of the inclined tube in the inclined tube sedimentation tank 4 is 1000 mm, and the installation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com