Organic silicon / hydroxyl phosphate composite modified water emulsion acrylic resin and preparation method and application thereof

A technology of acrylic resin and hydroxyphosphate, which is applied in coatings, anti-corrosion coatings, etc., can solve problems such as VOC emissions, achieve zero VOC emissions, excellent anti-corrosion performance, and improve cross-linking density and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

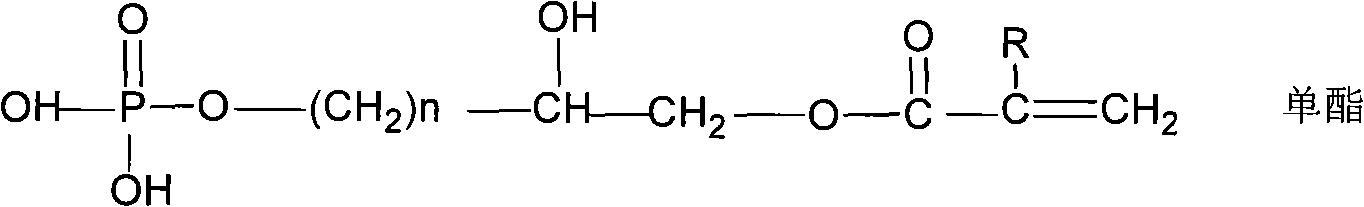

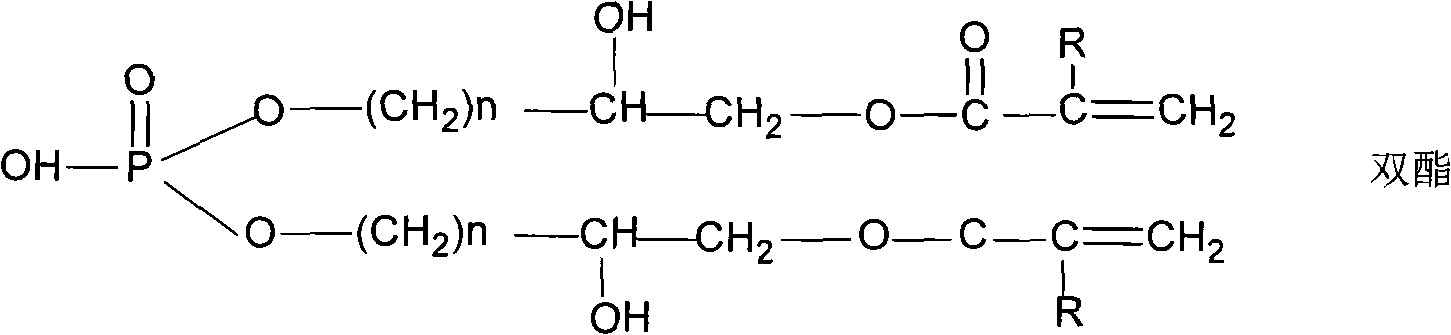

Method used

Image

Examples

Embodiment 1

[0041]First dissolve 0.25g initiator with 8.0g deionized water to obtain initiator solution; then add 30.0g deionized water, 0.25g pH regulator and 0.5g composite emulsifier into the reaction vessel, stir at high speed for 20 minutes, then add 1.2g of methyl methacrylate and 1.3g of butyl acrylate, stirred at high speed to emulsify and disperse, heated up to 70-90°C, added an appropriate amount of initiator solution, and kept warm for 15 minutes after the reaction system showed obvious blue light, and the composite emulsion core layer was obtained .

[0042] Put 12.0g of deionized water and 1.25g of composite emulsifier into the reaction vessel, and after stirring at high speed for 20 minutes, mix a mixture of 22.2g of butyl acrylate, 0.3g of methacrylic acid, 5.0g of hydroxypropyl acrylate, and 18.0g of styrene Add the monomer into the reaction vessel, emulsify and disperse at a high speed to prepare a mixed monomer pre-emulsion; then drop the mixed monomer pre-emulsion and t...

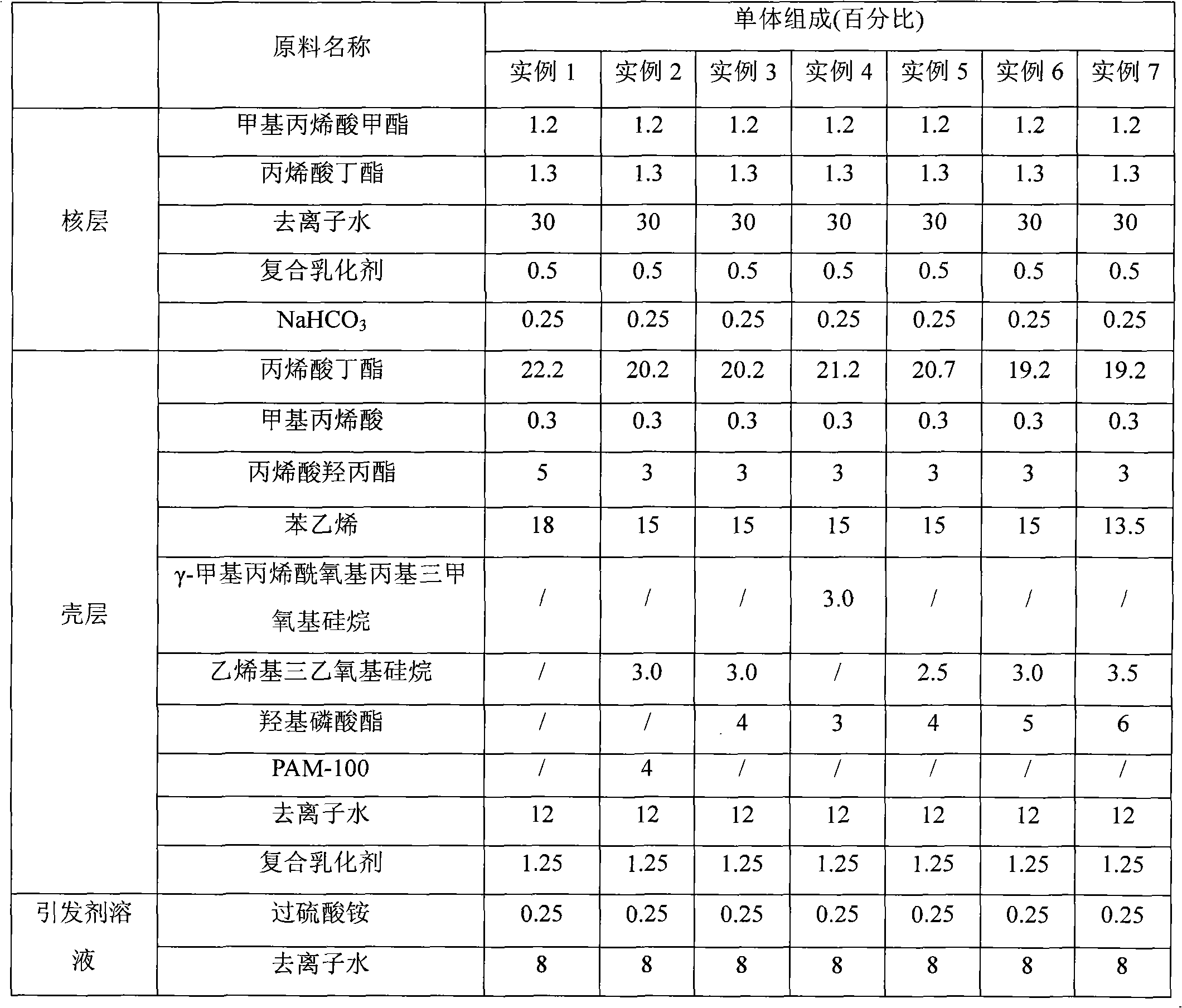

Embodiment 2~7

[0044] The operation steps and reaction conditions are the same as in Example 1, and the distribution ratio of each component is shown in Table 1. The properties of the obtained organosilicon / hydroxyphosphate composite modified water-emulsion acrylic resin are shown in Table 2.

[0045] Table 2

[0046] performance

Embodiment 8

[0048] Water-based metal baking paint: disperse 100 parts of dispersant and 10 parts of defoamer in 550 parts of water, then add 260 parts of iron red, 140 parts of talcum powder, 140 parts of barium sulfate, 20 parts of zinc oxide, and 20 parts of fumed silica , 370 parts of aluminum tripolyphosphate, 50 parts of zinc phosphate, in a disperser at 2500rpm, disperse evenly at a high speed, then transfer to a sand mill for grinding for 3 hours, until the fineness is less than 30μm, discharge, and then take out 15 parts of For red paste, add 30 parts of water-emulsion acrylic resin prepared in Example 1, 4 parts of aldehyde methyl etherified amino resin, 0.05 part of wetting agent, and 1 part of adhesive agent under high-speed stirring, and stir thoroughly, and finally add an appropriate amount of organic amine Neutralizer and deionized water adjust the pH and viscosity of the system. The properties of the paint are shown in Table 3.

[0049] The resins prepared in the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com