Accurate filling equipment and method for high temperature heat pipe requiring small amount of alkali metal working medium

A high-temperature heat pipe and alkali metal technology, which is applied in the field of quantitative filling equipment for high-temperature heat pipe solid alkali metal working medium, can solve the problems of complex heating process operation of storage tanks, inaccurate quality control of alkali metal processing, and insufficient vacuum degree of high-temperature heat pipes, etc. , to achieve the effect of small volume, avoid improper operation and convenient arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

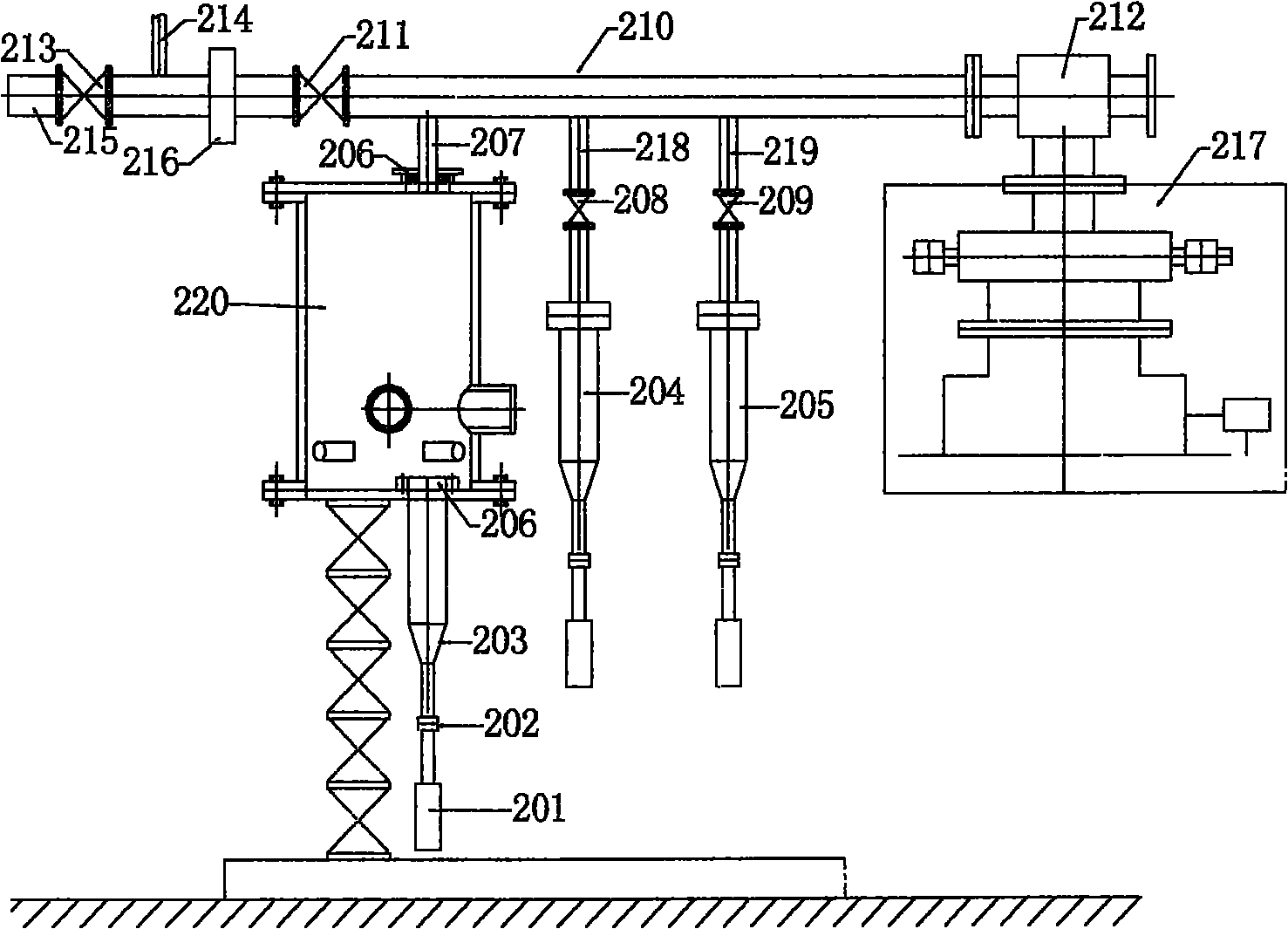

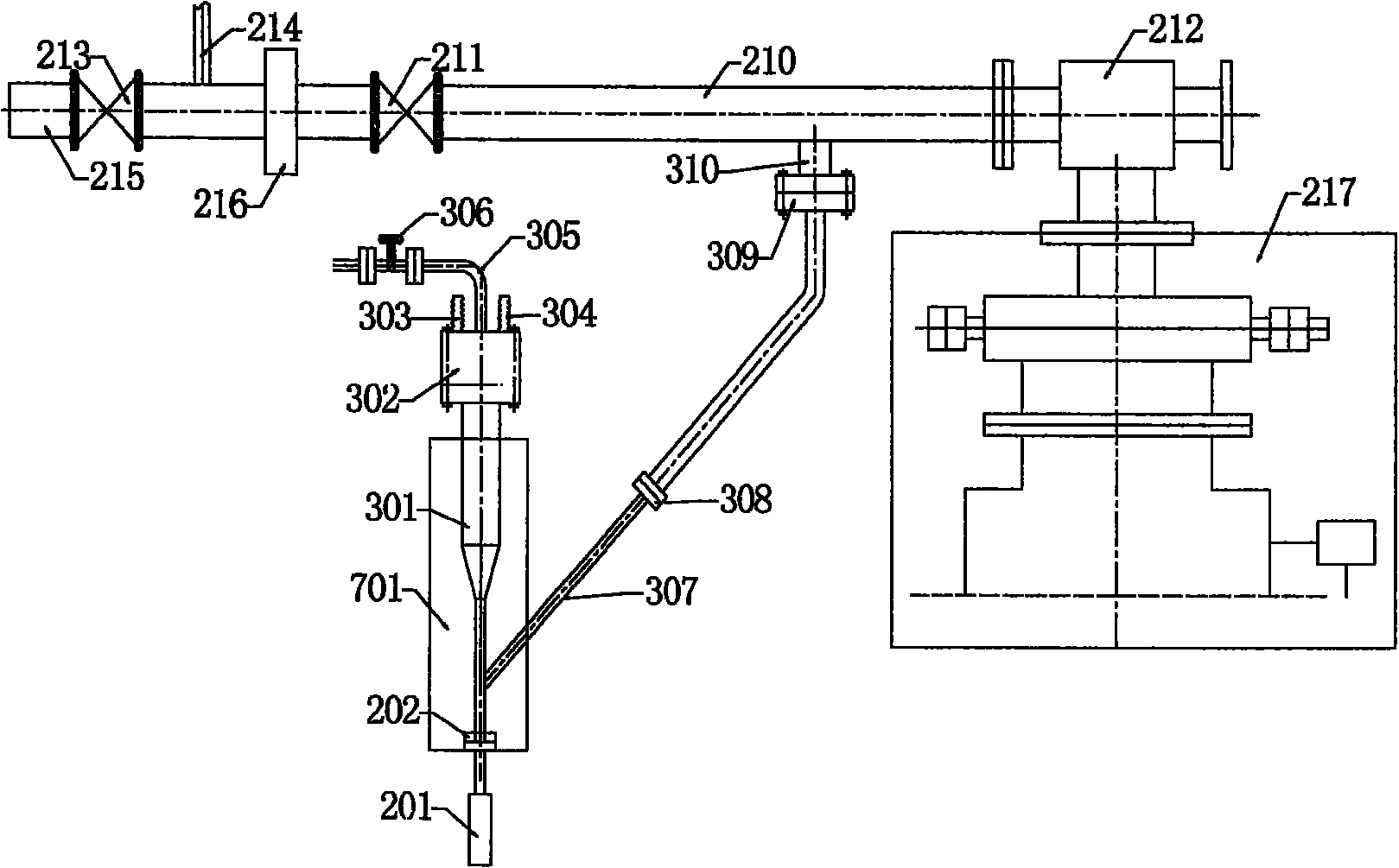

[0108] refer to Figure 3 to Figure 8 . exist image 3 An implementation of the quantitative filling equipment of the present invention is given in , which can fill the solid alkali metal working medium at room temperature into the high-temperature heat pipe. Taking sodium, which is common in alkali metals, as an example, the structure of the quantitative filling equipment and how to use the quantitative filling equipment to fill the process of working fluid will be described below.

[0109] In the process of loading sodium into the storage tank, the sodium in simple form is easily oxidized, which affects the purity of the working fluid. In order to overcome this problem, the quantitative filling device of the present invention also requires a transparent chamber 401 . When sodium is loaded into the branch pipe storage tank 301 using a transparent chamber, it is first necessary to follow the image 3 Assemble the various parts of the quantitative filling equipment, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com