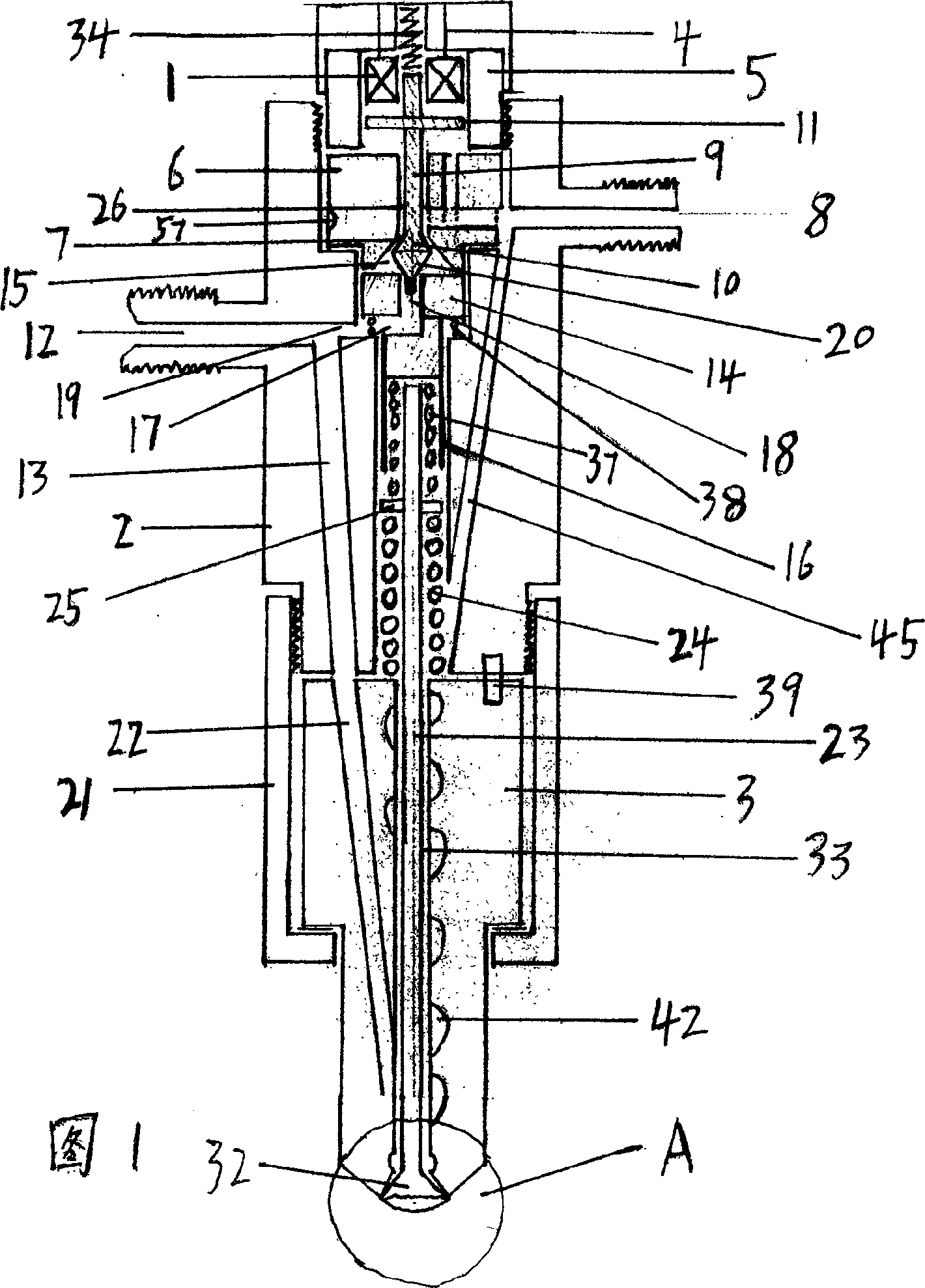

At present, the fuel injectors (nozzles) used in various electronically controlled fuel systems are all inward-opening fuel injectors. The biggest

disadvantage of the inward-opening fuel injectors is that the liquid flow area of the

fuel injection hole cannot be adjusted.

[0003] Because the

fuel injection hole is the final outlet of fuel, the uncontrollability of the fuel injection hole limits the fuel injection characteristics and

spray characteristics, making the fuel

injector unable to achieve the ideal fuel injection effect under various engine operating conditions. From the formula

m

=

pihj

.

L

d

.

t

It can be seen from the figure that when the unit time t and the

single injection quantity L are constant, the fuel injection atomization

mass m is equal to the ratio m of the fuel

injection pressure pinj to the cross-sectional area d of the fuel injection hole, and this ratio m is proportional to pinj, It is inversely proportional to d. When pinj is constant, if the set value of d is large (

heavy load condition), under

light load condition, especially idle condition, since L is small, m will be small, causing engine

idle speed instability or excessive

idle speed. High, which is an important reason for the high idle emission of the engine. It also makes the engine idle fuel consumption too high. When the set value of d is small (under medium and small loads), the

fuel supply per unit time is insufficient when the engine is working under

heavy load conditions. The fuel injection duration can only be extended to meet the fuel

injection volume requirements of the engine under

heavy load conditions, which is equivalent to prolonging the time of

diffusion combustion, deteriorating the

thermal efficiency of the engine, reducing power, increasing fuel consumption, and increasing

soot particles in the exhaust , after the pinj is increased, the duration of the same fuel injection is shortened, but at high speed and heavy load, the penetration distance of the oil beam increases, the amount of

oil mist hitting the wall increases, and the atomization is not good, and there are still problems in the existing technology to increase the pinj a series of technical problems

[0004] Another

disadvantage of the inner-opening injector is: the throttling effect between the

needle valve sealing cone surface and the seat surface makes the fuel pressure in the pressure chamber and the real

injection pressure lower and the injection hole is fixed, resulting in the engine running in small and medium The throttling effect is more obvious at load, especially at

idle speed, the fuel atomization

mass m is small, and the atomization is poor

[0005] The third

disadvantage of the inner open injector is: the existence of the pressure chamber volume

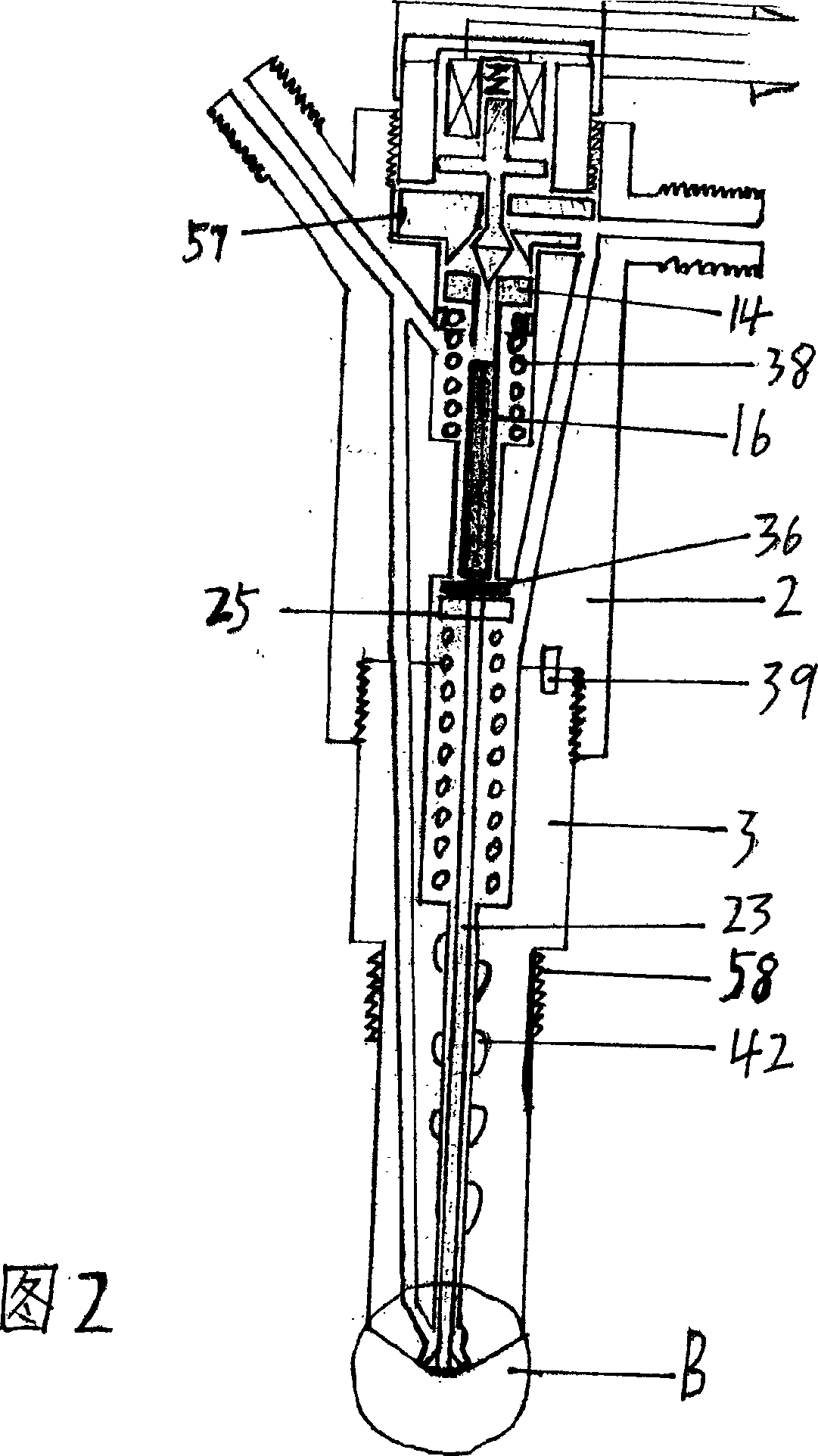

[0007] When the oil outlet hole is equal to the oil inlet hole, the

needle valve lifting pattern is a

sinusoidal waveform with equal sides, that is, the fuel

injection rate graph is also in a

sine wave shape. The hole must be smaller than the oil inlet hole, and the oil inlet hole must be large enough relative to the

diameter of the control

piston to ensure oil

cut-off, but the oil outlet hole must also be large enough relative to the

diameter of the control

piston, if it is too small, the

needle valve will rise If the speed is too slow, the

response characteristics of the injector will be affected. The

diameter of the oil outlet hole is limited by the

maximum pressure that the

solenoid valve can withstand. If the diameter of the oil outlet hole is too large, the negative

cut-off pressure of the

solenoid valve will be large, and the

electromagnetic coil will heat up. even

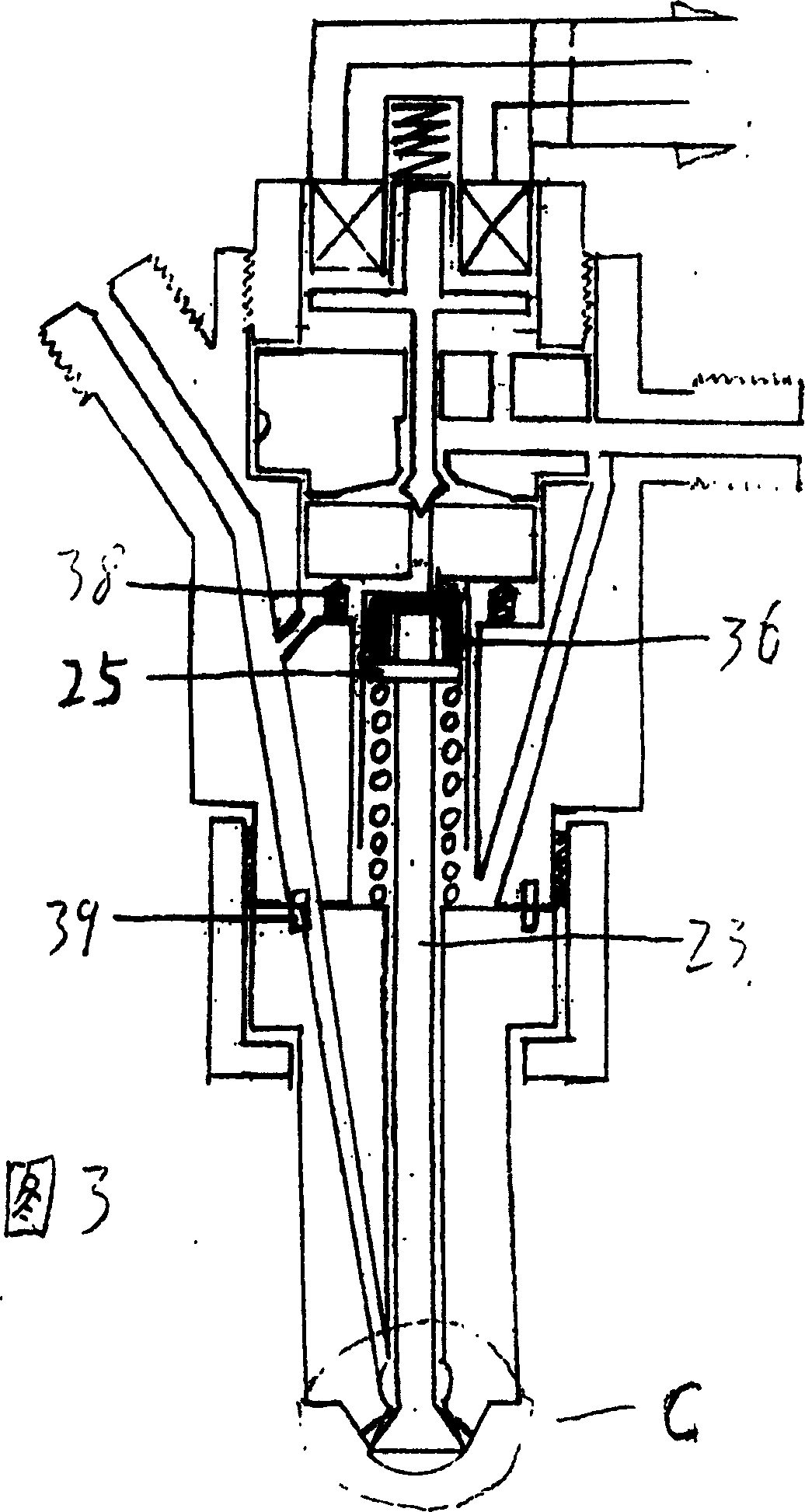

burn out[0008] The technical difficulty of the above-mentioned electronically controlled fuel injection system represented by Denso ECD-U2 is the determination of the parameters between the diameter of the oil outlet hole, the diameter of the oil inlet hole and the diameter of the control

piston. This problem (the diameter of the oil inlet and outlet holes should reach a liquid flow difference of ±1% as much as possible), limits the

response characteristics of the electronically controlled fuel injection system represented by ECD-U2, that is, the diameter of the oil outlet hole, the diameter of the oil inlet hole and the The design flexibility of controlling the diameter of the piston is relatively narrow, but the determination also determines the inclination of the shape of the fuel

injection rate. When the fuel

injection pressure is constant, the fuel injection quantity can only be controlled by the width of the command pulse (

duty cycle)

[0009] In general, the existing electronically controlled fuel injectors have not yet achieved real fuel injection

rate control, so that the electronically controlled fuel injectors cannot adapt well to the needs of the engine, especially when the load changes greatly (that is, the

fuel supply changes Large) high-speed high-power

internal combustion engine fuel injection needs

Login to View More

Login to View More  Login to View More

Login to View More