Coating line with full-automatic control and manual spray coating

A fully automatic, coating line technology, applied in the direction of surface coating device, spray device, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

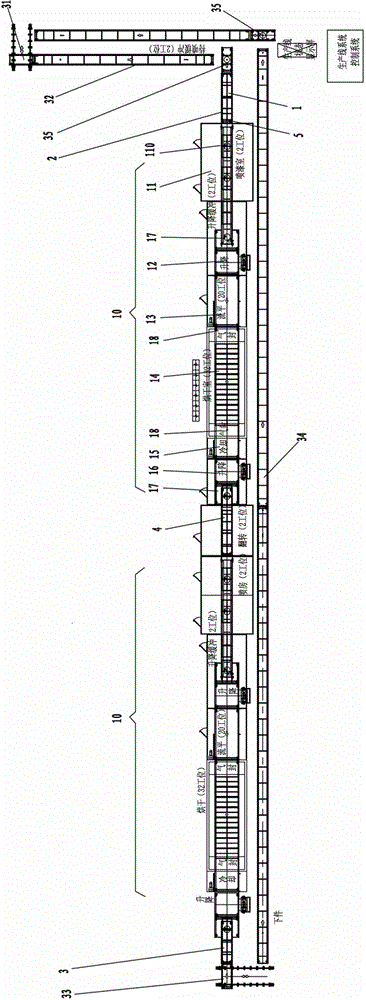

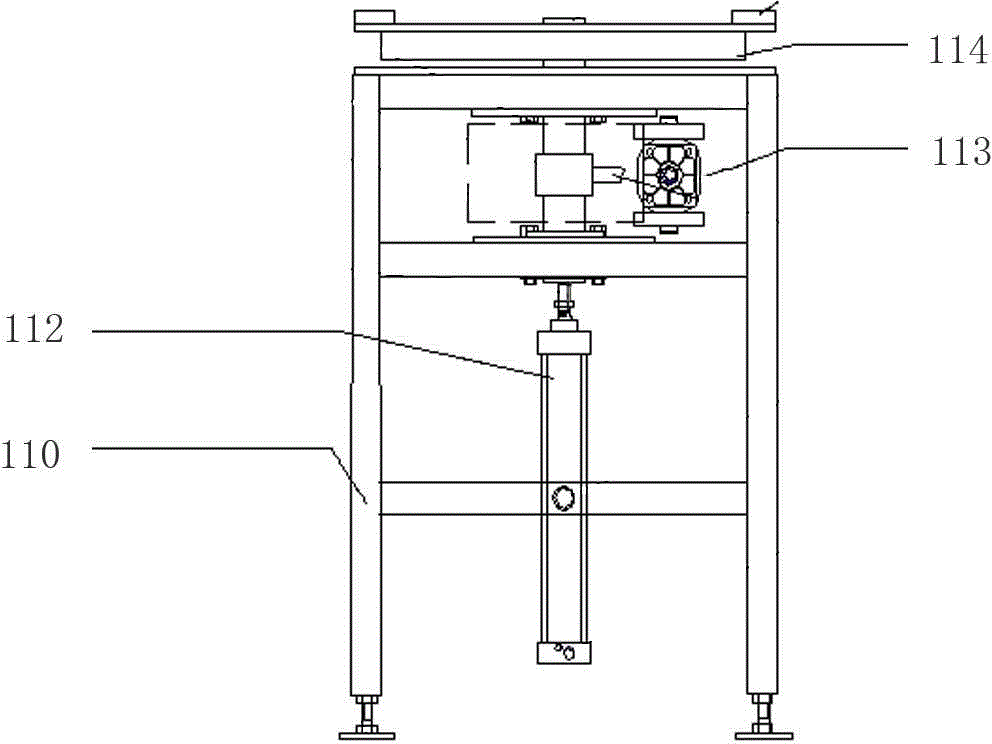

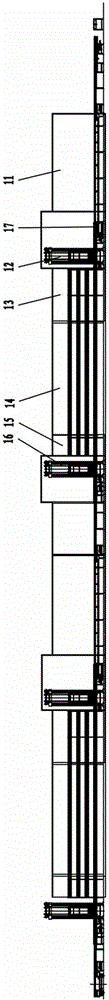

[0043] Such as figure 1 and figure 2 As shown, a coating line with automatic control and manual spraying is equipped with a linear double-speed upper conveyor chain 1 on the manual operation plane on the ground. Parts area 3, between the area to be sprayed 2 and the next area 3, a coating line 10, an overturning platform 4 and a coating line 10 are arranged in sequence; There are paint spraying chamber 11, inlet lifting device 12, leveling chamber 13, drying chamber 14, cooling chamber 15 and outlet lifting device 16 in sequence, and air sealing devices 18 are respectively arranged at both ends of each drying chamber; conveyor chain 1 The accumulative system 5 is set at the station with manual operation throughout the whole process, and the accumulative system 5 is connected with the automatic control system outside the conveyor chain 1 .

[0044] This design is designed as an assembly line coating equipment according to the process flow, and the process flow is: upper piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com