Microwave sterilizing device for sterilization in high performance under low temperature and normal pressure

A technology of microwave sterilization and sterilizer, which is applied in packaging sterilization, food science, food preservation, etc. It can solve problems such as mutual interference, insufficient concentration of microwaves, and changes in food nutrition, so as to prevent microwave leakage, high concentration of microwaves, and prevent The effect of microwave leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

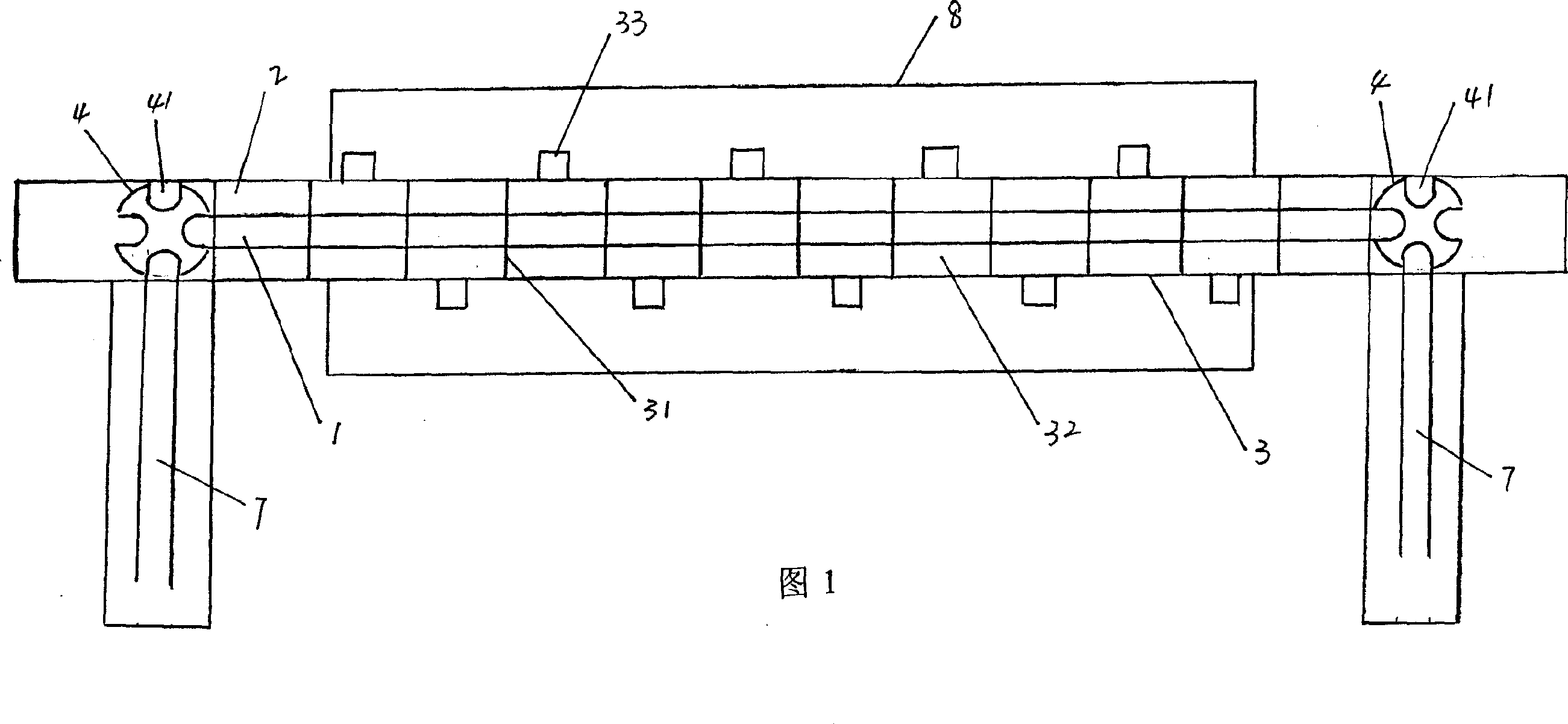

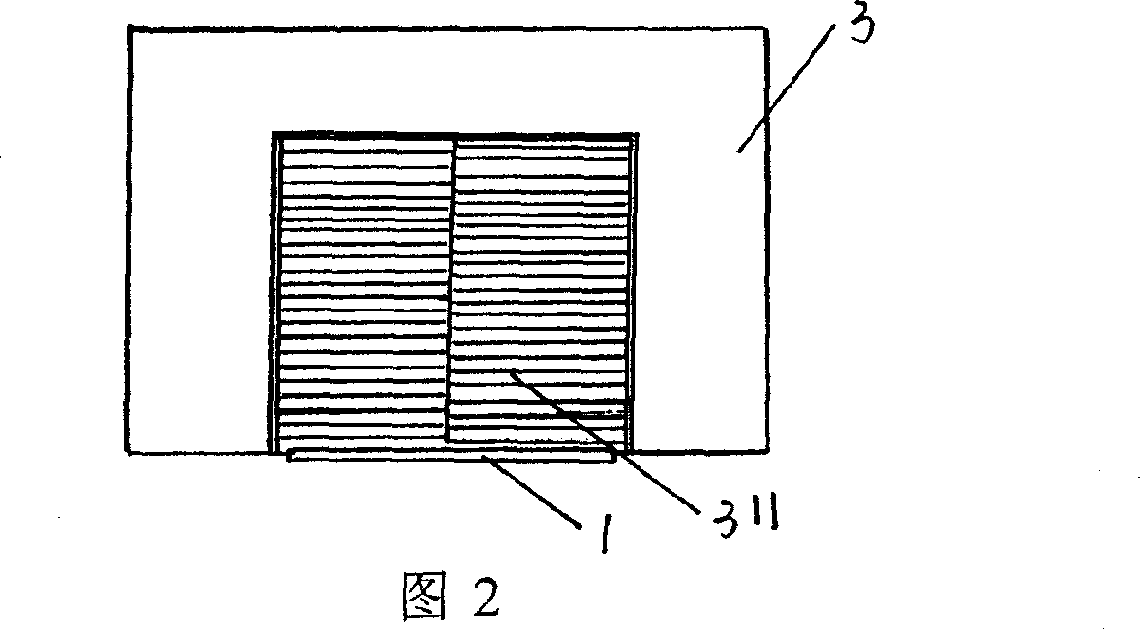

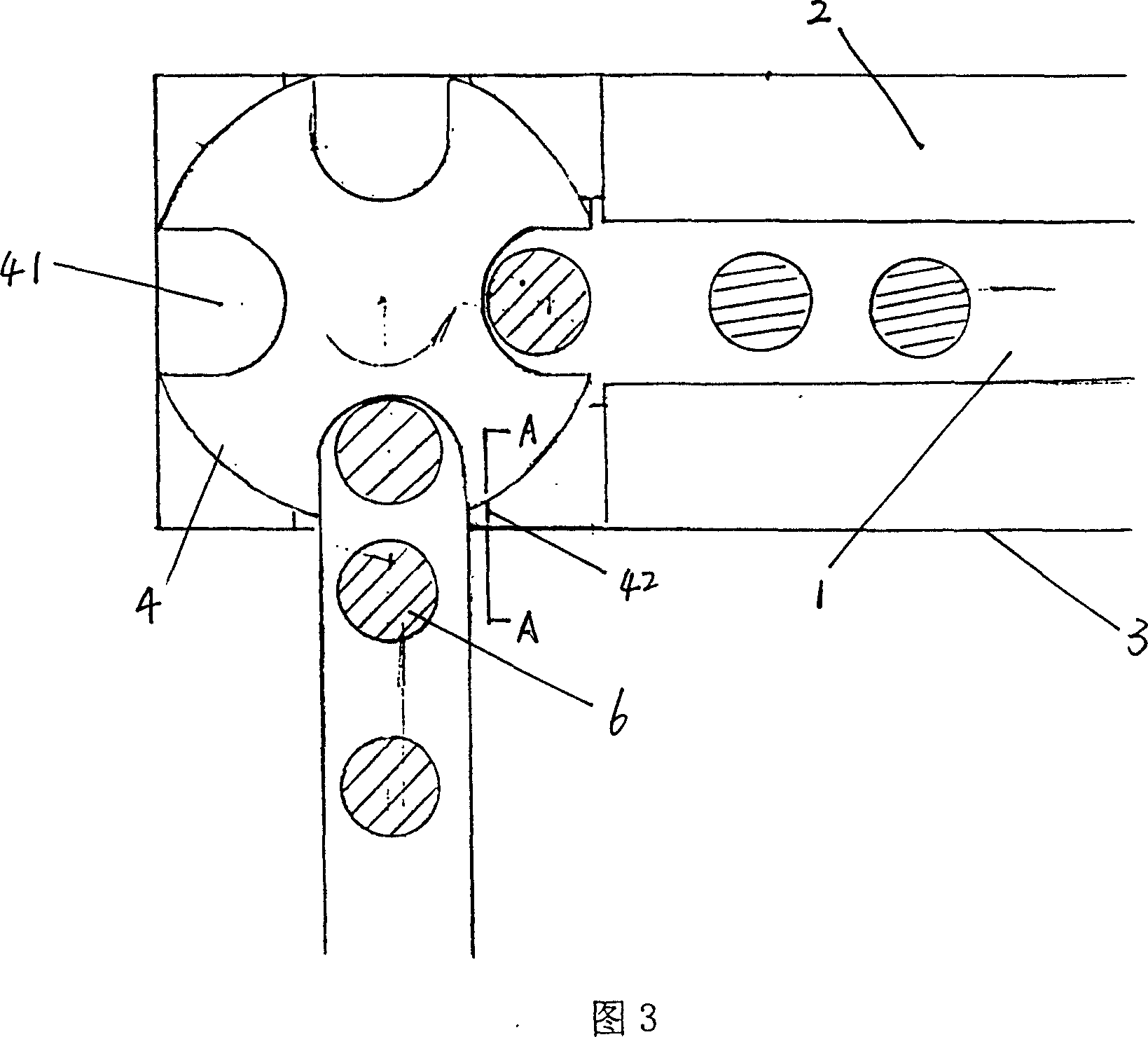

[0028]As shown in Figure 1, the microwave sterilizer of the present invention includes a metal endless conveyor belt 1 for conveying sterilized articles, a metal bracket 2 for supporting the conveyor belt, a metal sealed box 3 on the conveyor belt, and the middle part of the sealed box Divided into ten independent microwave radiation chambers 32 by metal partitions 31, the middle of each metal partition is a double-comb-shaped metal elastic partition 311, and the two sides of the partition are fixed on the metal partition, as shown in Figure 2 As shown, the length, width and height of each microwave radiation chamber are: 300mm × width 200mm × height 250mm, each radiation chamber 32 side wall is provided with a microwave generator 33, and the power of each microwave generator is: 0.8KW, corresponding to The microwave generators of the two adjacent microwave radiation chambers are symmetrically arranged relative to the forward direction of the conveyor belt, that is, the microwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com