Microwave digestion furnace chamber

A technology of microwave digestion and furnace cavity, which is applied in the field of analytical chemical instruments, can solve problems such as hidden safety hazards and difficult operation, and achieve the effects of preventing microwave leakage, improving work efficiency, and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

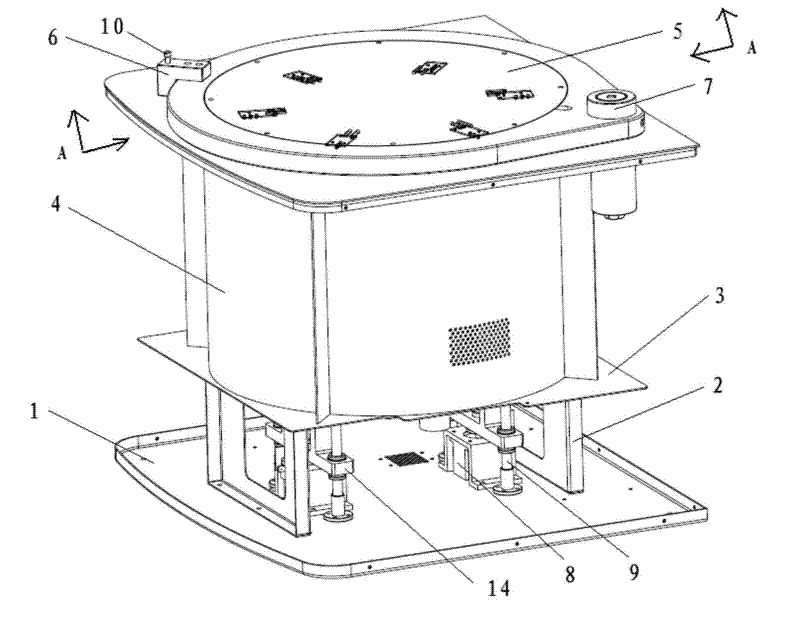

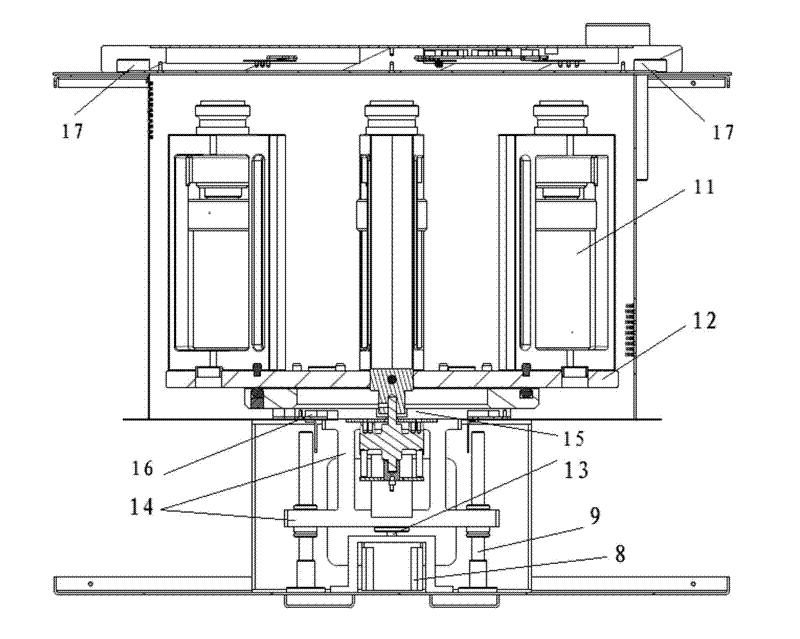

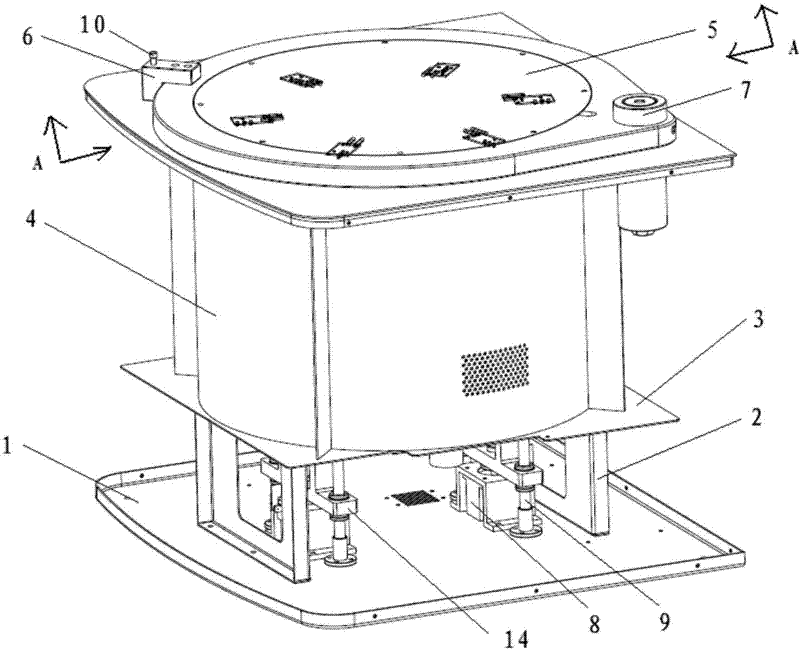

[0032] This specific embodiment will be further described in conjunction with the accompanying drawings.

[0033] refer to figure 1 and figure 2 It can be seen that a microwave digestion cavity includes a base 1, a bracket 2, a bottom plate 3, a cavity 4, a movable cover 5, a buckle 6, a rotating shaft 7, a motor 8, a sliding rod 9, a shaft 10, a digestion tank 11, and a turntable 12. Strut 13, lifting part 14, movable bottom plate 15, anti-flow groove 16 and anti-flow groove 17.

[0034] The bracket 2 is fixedly connected between the base 1 and the base plate 3 , the base plate 3 is fixedly connected with a cavity 4 , the cavity 4 is provided with a movable cover 5 , and the movable cover 5 is movably connected with the cavity 4 through a rotating shaft 7 . Since the movable cover 5 is arranged on the top of the microwave digestion chamber cavity 4, if the pressure relief of the microwave digestion chamber is insufficient or not timely during use, the movable cover 5 will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com