Production method using microwaves to melt aluminum silicate minerals and microwave equipment

A production method, aluminum silicate technology, applied in the direction of aluminum silicate, silicate, microwave heating, etc., can solve the problems of refractory melting, high energy consumption, high melting point, etc., achieve energy consumption reduction, stable performance, and increase production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a production method of microwave melting aluminum silicate minerals, comprising the following steps:

[0032] (1) roasting aluminum silicate minerals;

[0033] (2) Pulverizing the aluminum silicate minerals roasted in step (1) to obtain aluminum silicate mineral powders with a particle size of 40 meshes;

[0034] (3) The aluminum silicate mineral powder is pressed into balls to obtain a diameter of 35mm and a density of 3.5g / cm 3 aluminum silicate mineral balls;

[0035] (4) Put the aluminum silicate mineral ball into microwave equipment and heat and melt at 1800° C. to complete the production of the microwave-melted aluminum silicate mineral.

Embodiment 2

[0037] The invention provides a production method of microwave melting aluminum silicate minerals, comprising the following steps:

[0038] (1) roasting aluminum silicate minerals;

[0039] (2) Pulverizing the aluminum silicate minerals roasted in step (1) to obtain aluminum silicate mineral powders with a particle size of 80 meshes;

[0040] (3) The aluminum silicate mineral powder is pressed into balls to obtain a diameter of 25mm and a density of 3.6g / cm 3 aluminum silicate mineral balls;

[0041] (4) Put the aluminum silicate mineral balls into microwave equipment and heat and melt at 2100° C. to complete the production of the microwave melted aluminum silicate minerals.

Embodiment 3

[0043] The invention provides a production method of microwave melting aluminum silicate minerals, comprising the following steps:

[0044] (1) roasting aluminum silicate minerals;

[0045] (2) Pulverizing the aluminum silicate minerals roasted in step (1) to obtain aluminum silicate mineral powders with a particle size of 50 meshes;

[0046] (3) The aluminum silicate mineral powder is pressed into balls to obtain a diameter of 30mm and a density of 3.5g / cm 3 aluminum silicate mineral balls;

[0047] (4) putting the aluminum silicate mineral ball into a microwave device and heating and melting at 2000° C. to complete the production of the microwave melting aluminum silicate mineral;

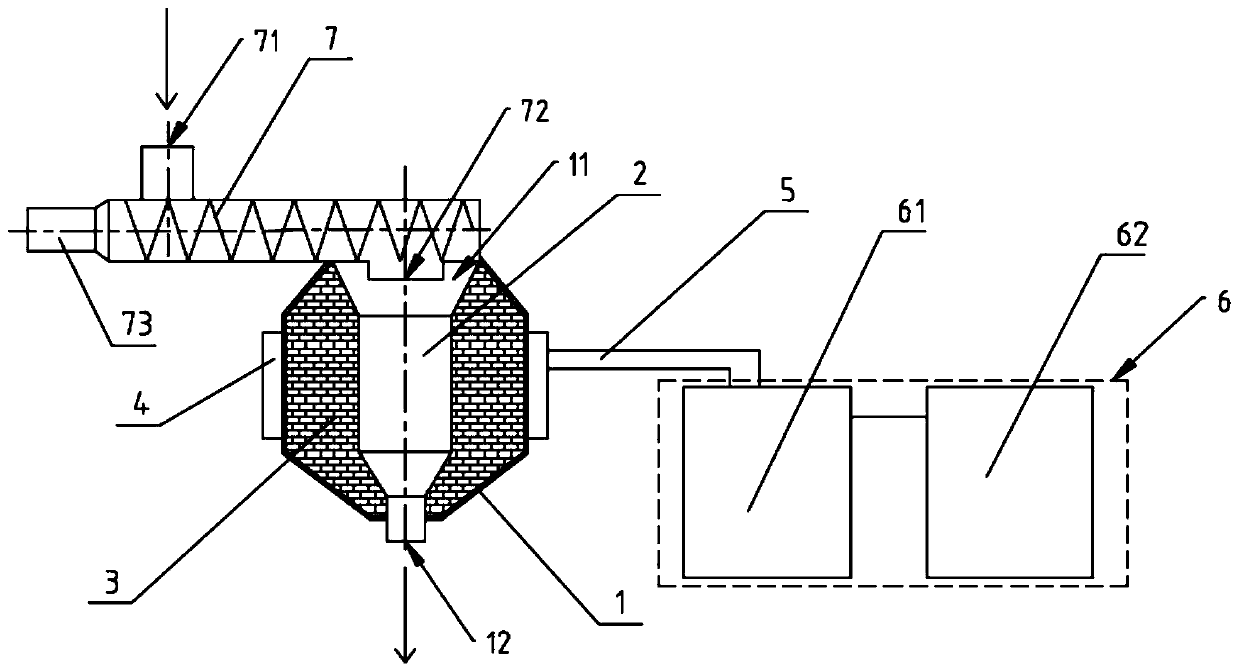

[0048] The present invention also provides the above-mentioned microwave equipment, including a furnace body 1 and a furnace cavity 2 inside the furnace body 1, and a refractory material insulation layer 3 is arranged between the furnace body 1 and the furnace cavity 2;

[0049] A microwave swir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com