Steam-microwave all-in-one machine

An all-in-one, exhaust fan technology, applied in steam cooking utensils, household heating, heating fuel, etc., can solve the problems of easy overflow of soup, residual condensed water, difficult to clean, etc., to avoid microwave leakage and steam leakage. , Improve the drying effect and speed up the gas flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

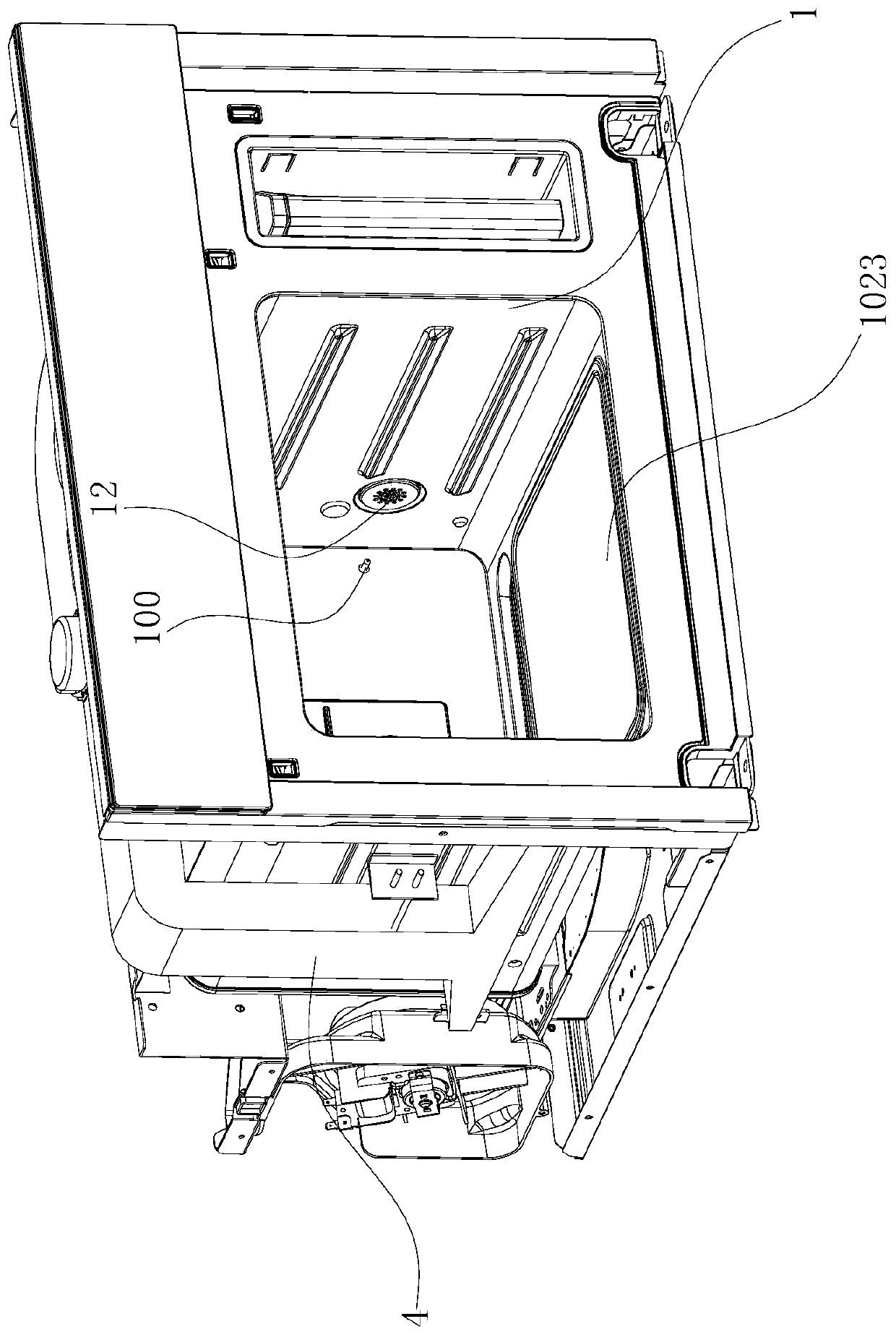

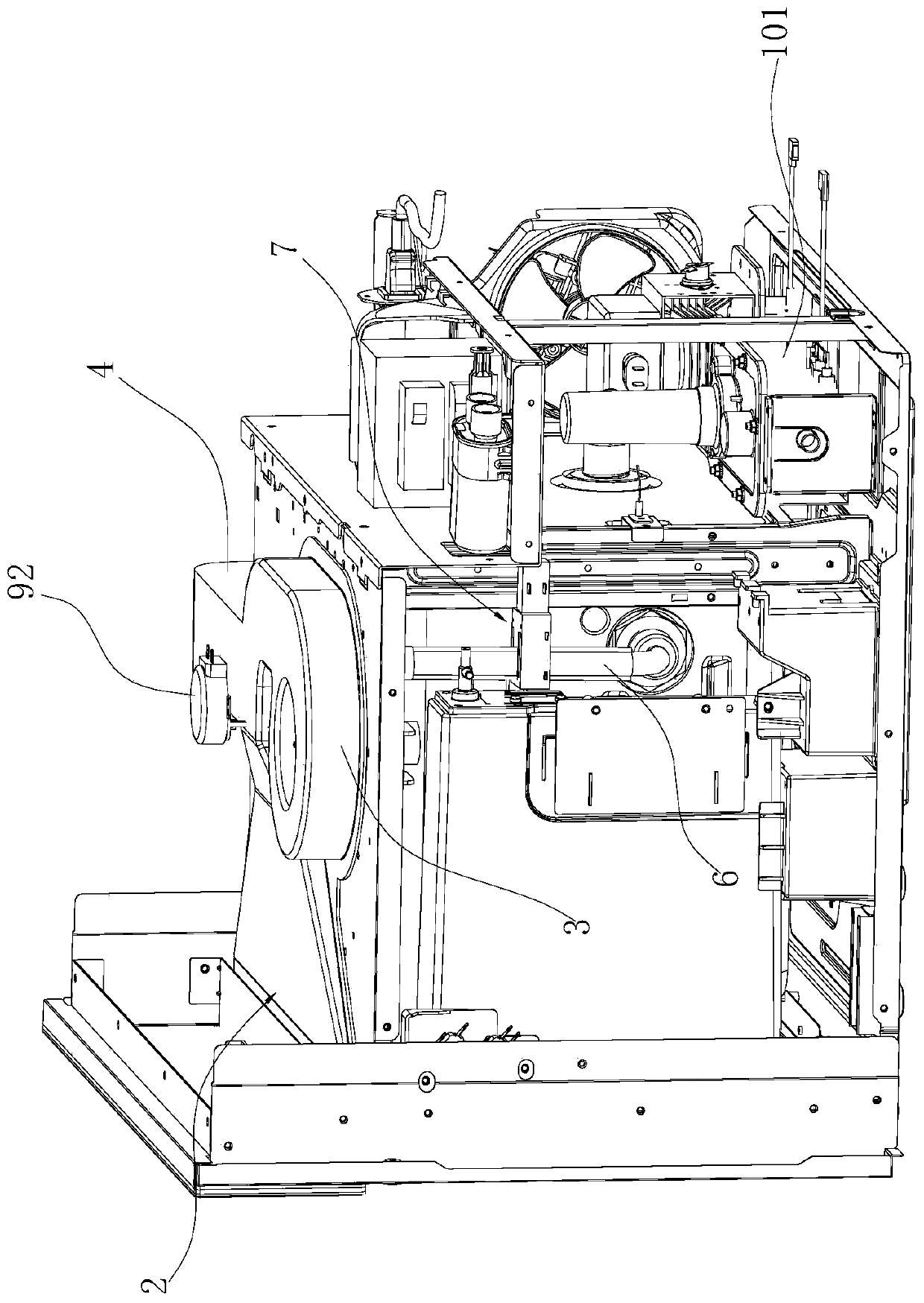

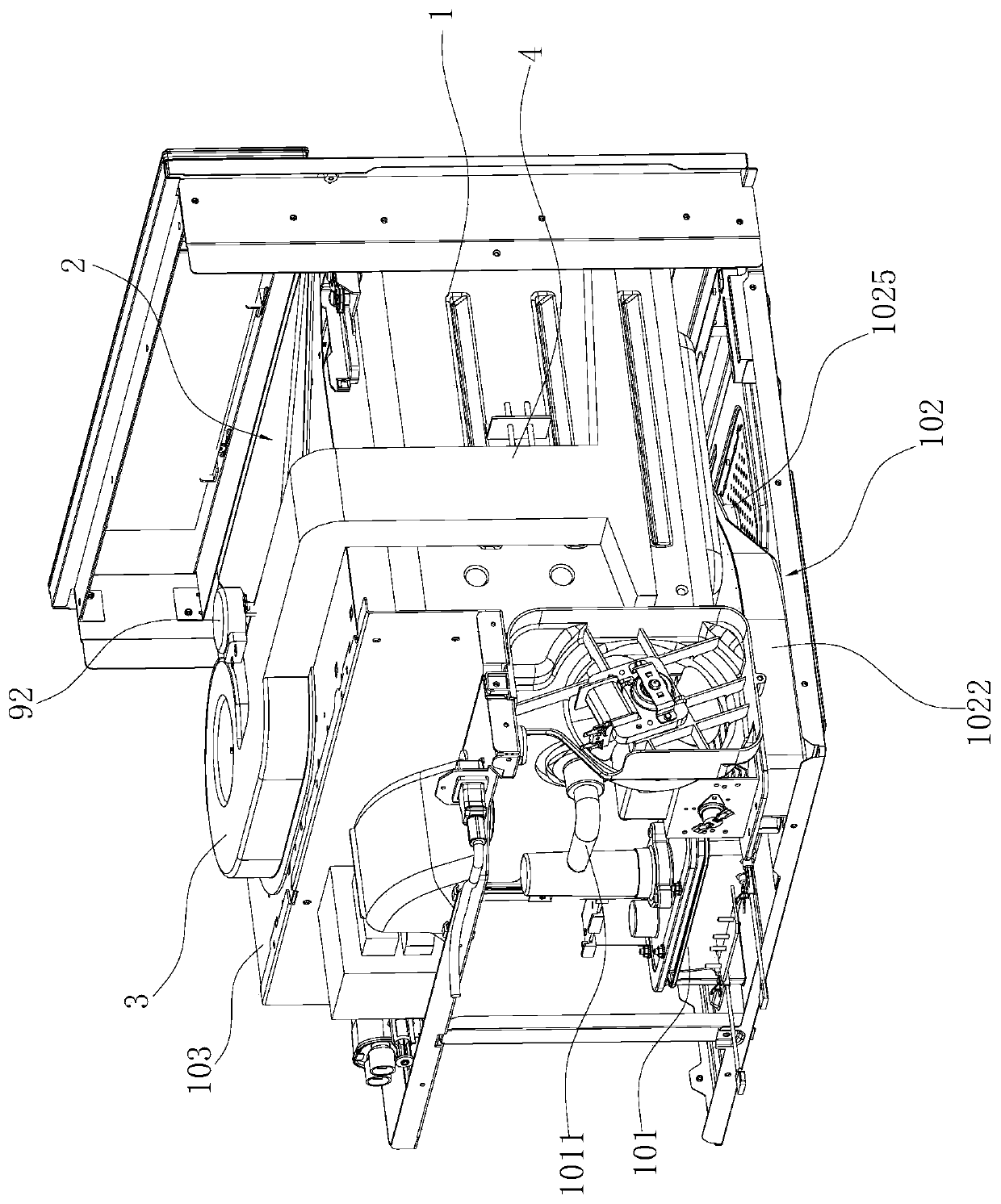

[0025] Such as Figure 1-8 As shown, an integrated steamer and microcomputer includes an inner container 1, an exhaust channel 2, a steam generator 101 and a microwave assembly 102. An upper mounting plate 103 is arranged above the inner container 1, and the above-mentioned exhaust channel 2 is arranged on the upper mounting plate. board 103. The steam generator 101 is arranged on the back side of the inner bag 1, and the inner bag 1 is provided with a steam inlet 14, and the steam outlet (not shown) on the steam generator 101 and the steam inlet 14 on the inner bag 1 pass through the inlet. The steam pipes 1011 are connected. The above-mentioned microwave assembly 102 is arranged below the liner 1, and the microwave assembly 102 includes a magnetron (not shown), a waveguide 1022, a glass-ceramic 1023, a stirrer 1024 and a stirrer for drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com