Microwave steam generating device and microwave humidifying device

A technology of steam generating device and humidifying device, which is applied in the direction of steam generation, steam generation method, induction heating device, etc., and can solve problems such as microwave leakage and harm to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

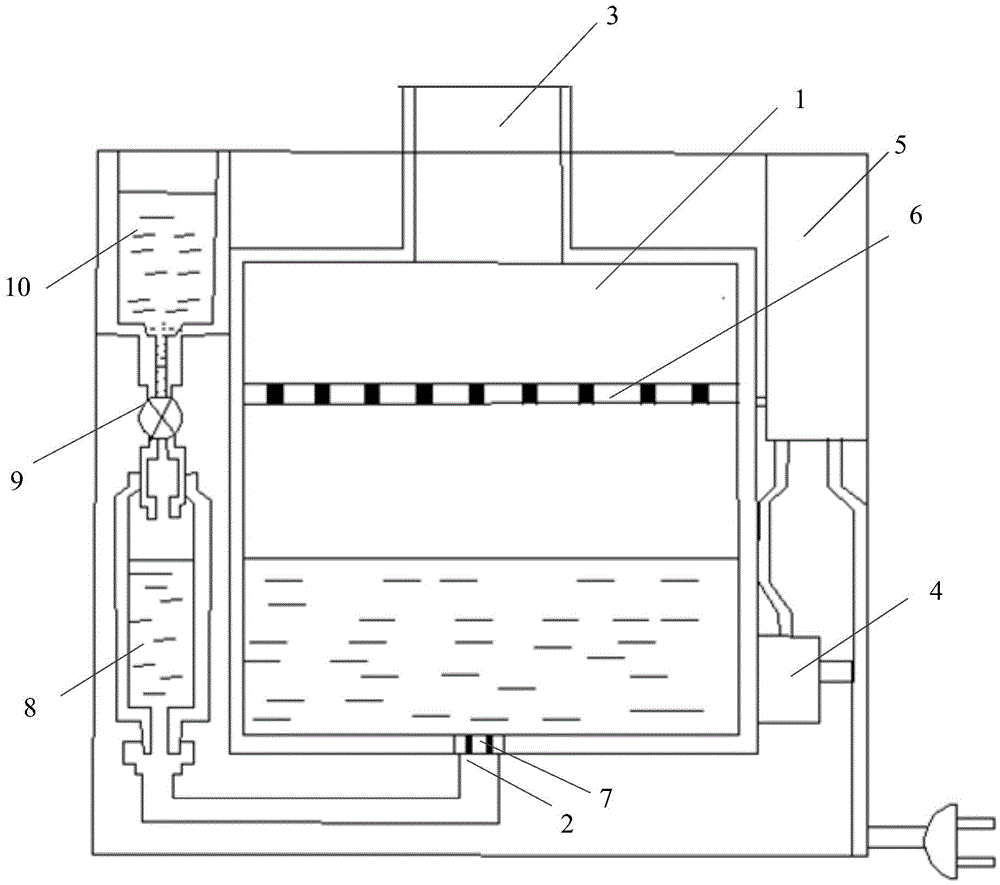

[0017] This embodiment provides a microwave steam generating device, such as figure 1 As shown, a stainless steel cylindrical tank-shaped body 1 is included as a cavity body for generating steam, and the tank-shaped body 1 is a cavity body with a water injection port 2 and a steam outlet 3, on the right side of the tank-shaped body 1 The bottom installs a magnetron 4 as a microwave generating device, and the magnetron 4 is connected with a microwave controller 5 installed on the outside of the tank 1, and the microwave controller 5 is connected with a power line for controlling the Magnetron 4, the tank-shaped body 1 is also provided with an upper microwave isolation net 6 located at the steam outlet 3 and a lower microwave isolation net 7 located at the water injection port 2 .

[0018] The mesh diameter of described upper microwave isolation net 6 and bottom microwave isolation net 7 is 4mm, and described upper microwave isolation net 6 is arranged on the 2 / 3 high position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com