Patents

Literature

65results about How to "Precise output control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

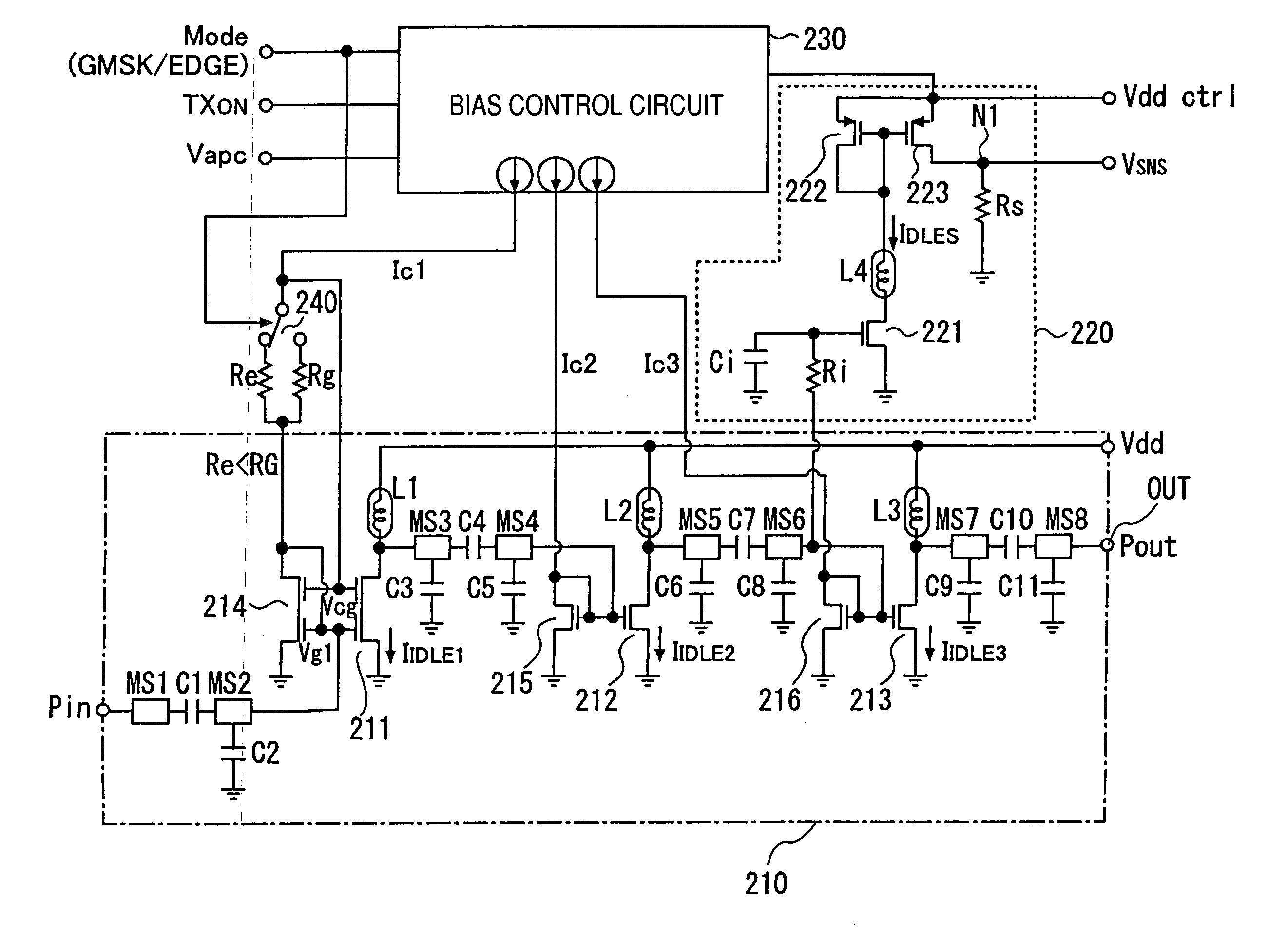

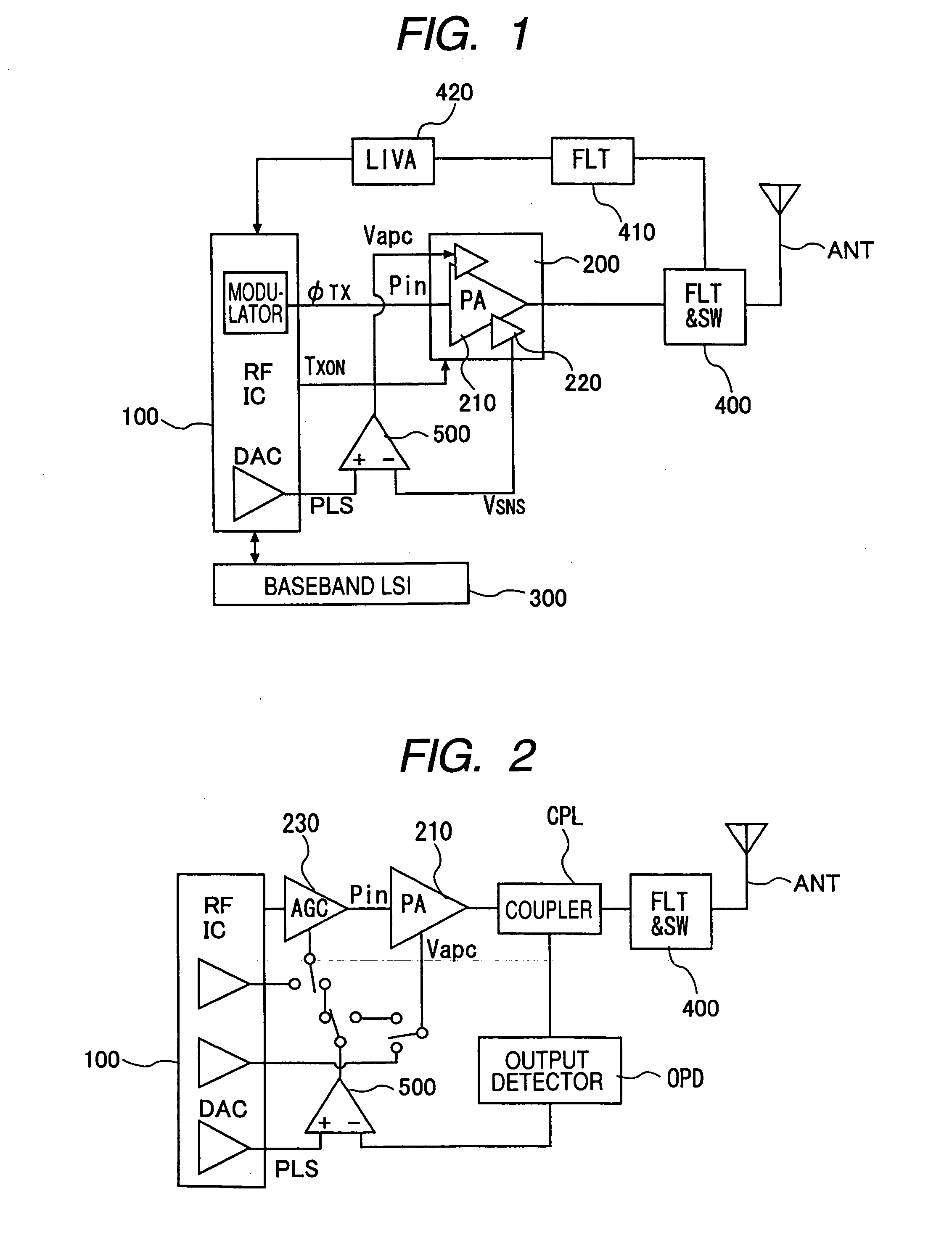

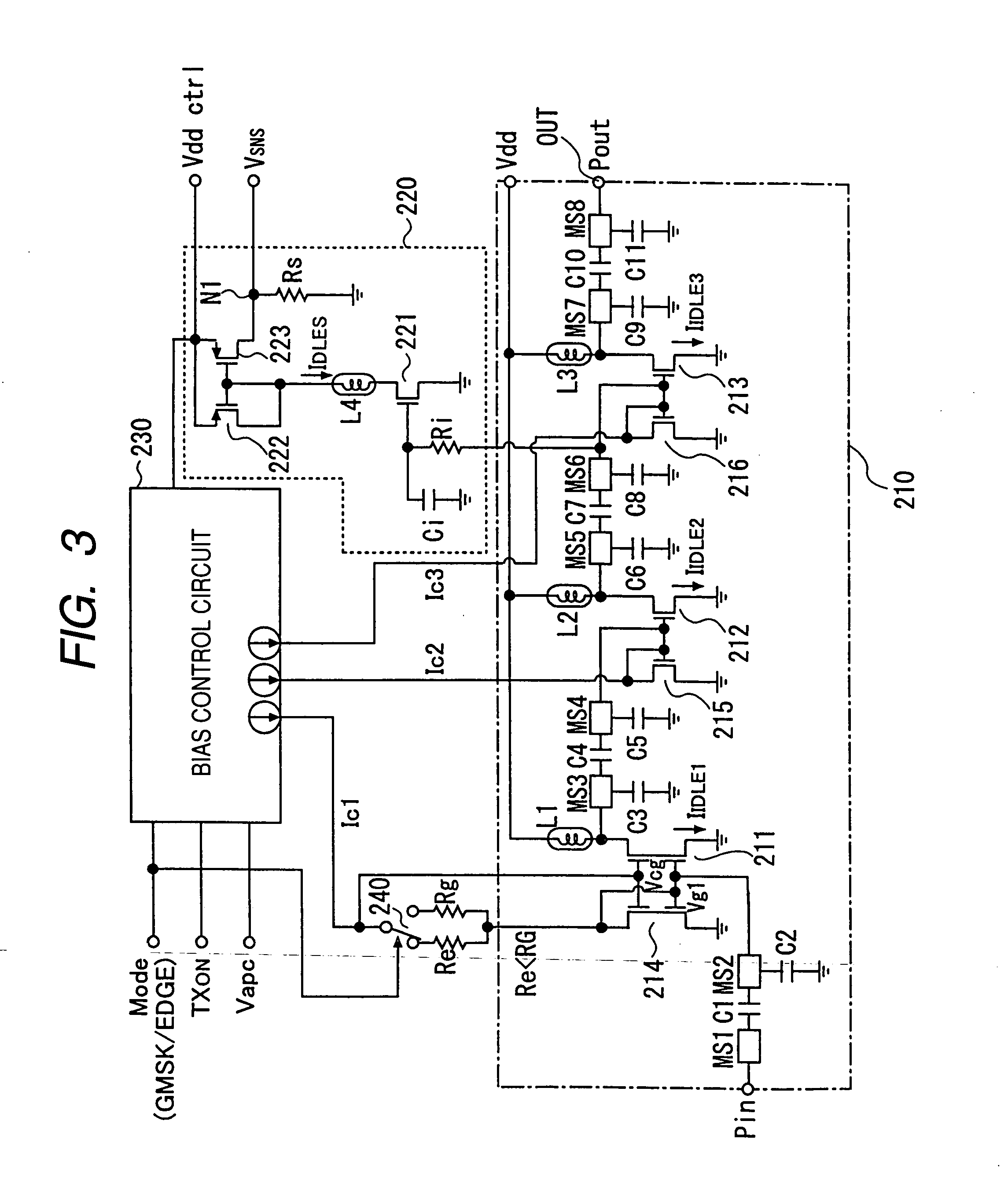

High-frequency power amplifier circuit and electronic part for communication

InactiveUS20050218989A1Simple control systemReduce gainGain controlAmplifier modifications to raise efficiencyHigh frequency powerAudio power amplifier

A wireless communication system has a first operation mode (GSM mode) for amplifying a phase-modulated high frequency signal with a high frequency power amplifier circuit and a second operation mode (EDGE mode) for amplifying a phase and amplitude-modulated high frequency signal with the amplifier circuit. The amplifier circuit has an input of a high frequency signal, with the amplitude and frequency being fixed in both the first and second operation modes, and operates by being controlled for the bias state of each amplifying stage in accordance with the output control signal produced by a control circuit based on the demanded output level (Vapc) and the detected output level (VSNS) so that the amplifier circuit performs signal amplification to meet the demanded output level.

Owner:MURATA MFG CO LTD

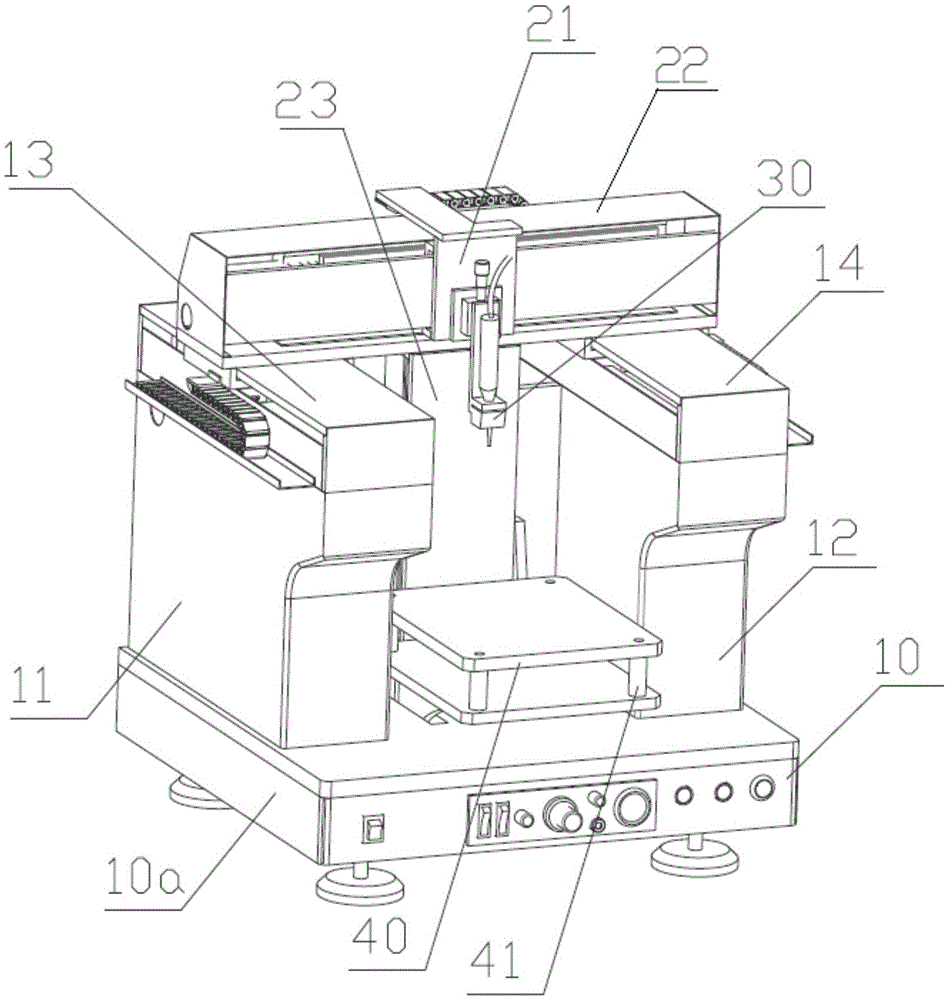

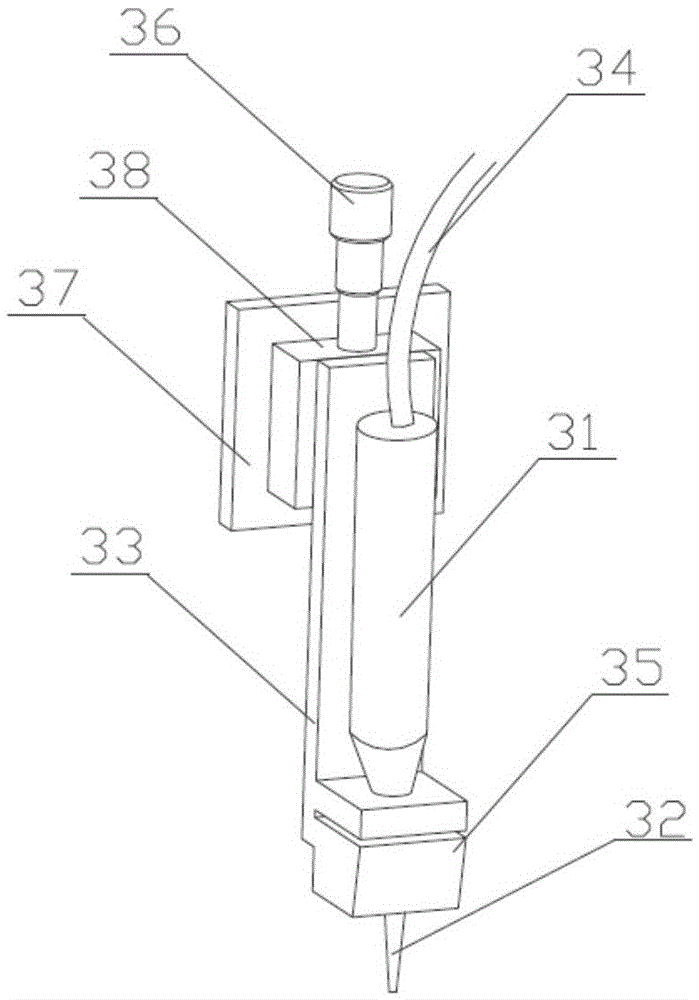

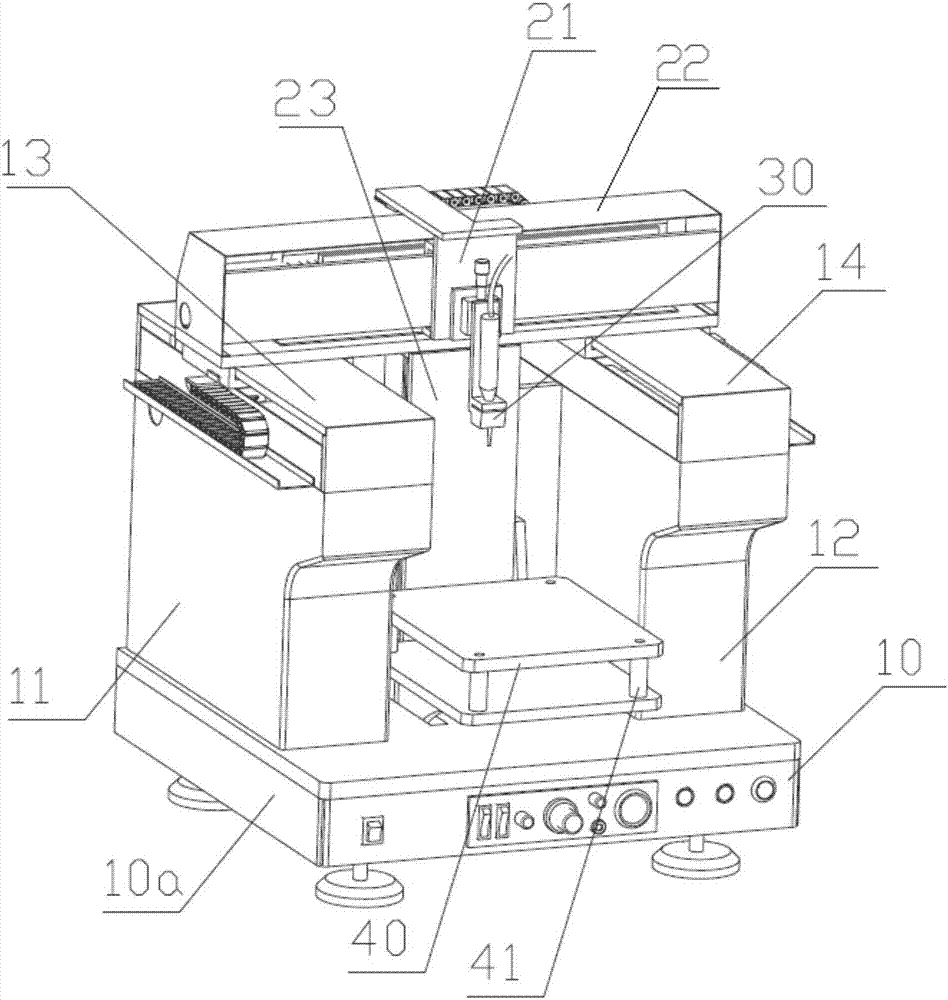

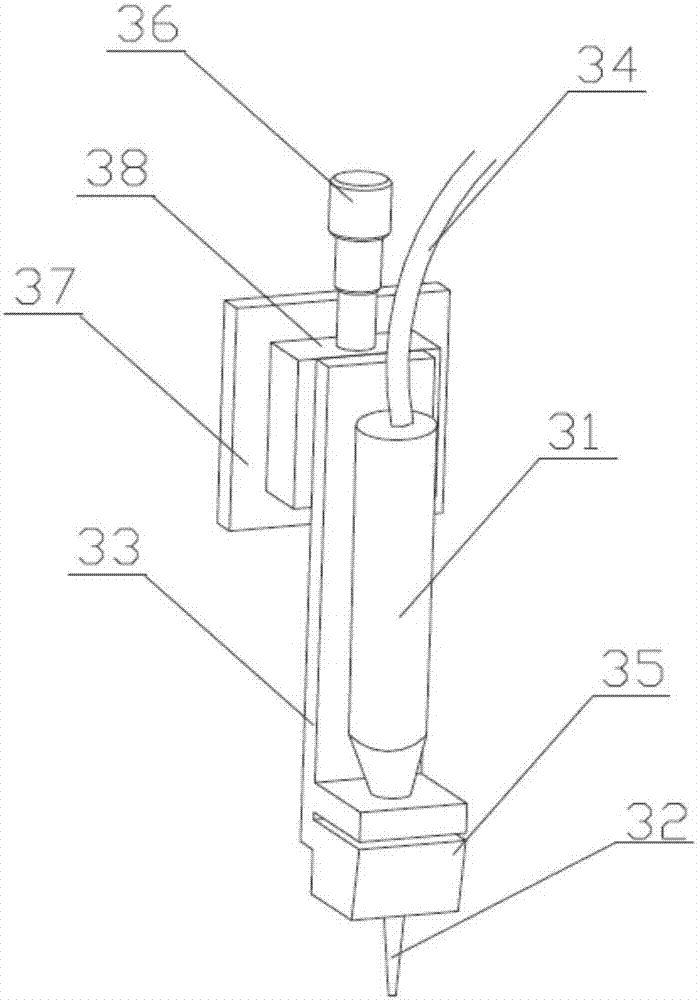

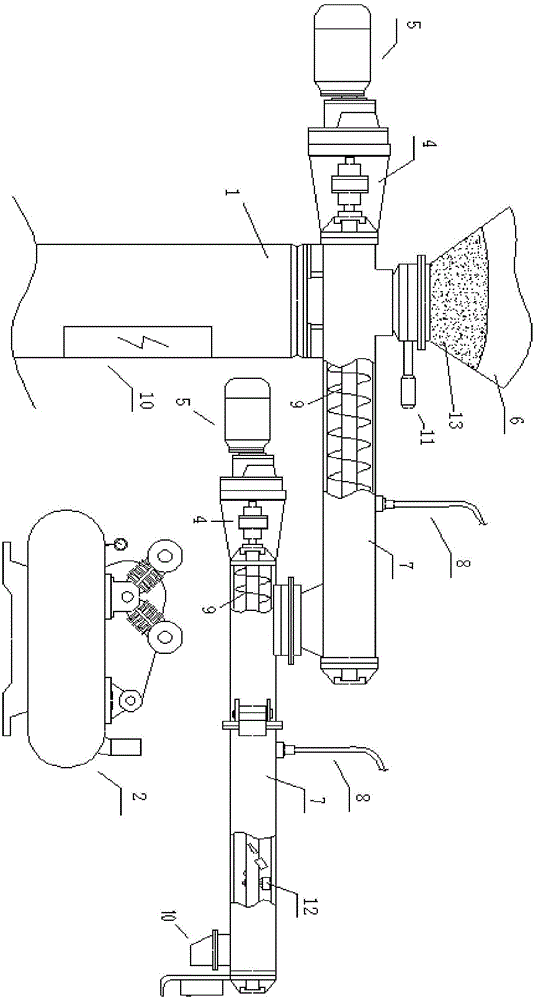

Silica gel 3D printer and silica gel product printing method

ActiveCN105643939AHigh precisionPrecise output controlAdditive manufacturing apparatusData informationEngineering

The invention provides a silica gel 3D printer and a silica gel product printing method. The silica gel printer comprises a frame, an X-axle slide module, a Y-axle slide module, a Z-axle slide module, a silica gel printing head and an air pressure adjusting module. A main control module is used for controlling the Z-axle slide module to drive a forming platform to change the position along a Z axle according to model data information of a silica gel product to be printed, controlling the X-axle slide module and the Y-axle slide module to drive the silica gel printing head to move along a predetermined path at a first predetermined speed, and controlling the air pressure adjusting module to adjust air pressure in the silica gel printing head so as to control the silica gel printing head to extrude out silica gel at a second predetermined speed. The silica gel printer has the beneficial effects of simple structure, low energy consumption and simple technological flow.

Owner:SHENZHEN ADVENTURE TECH CO LTD

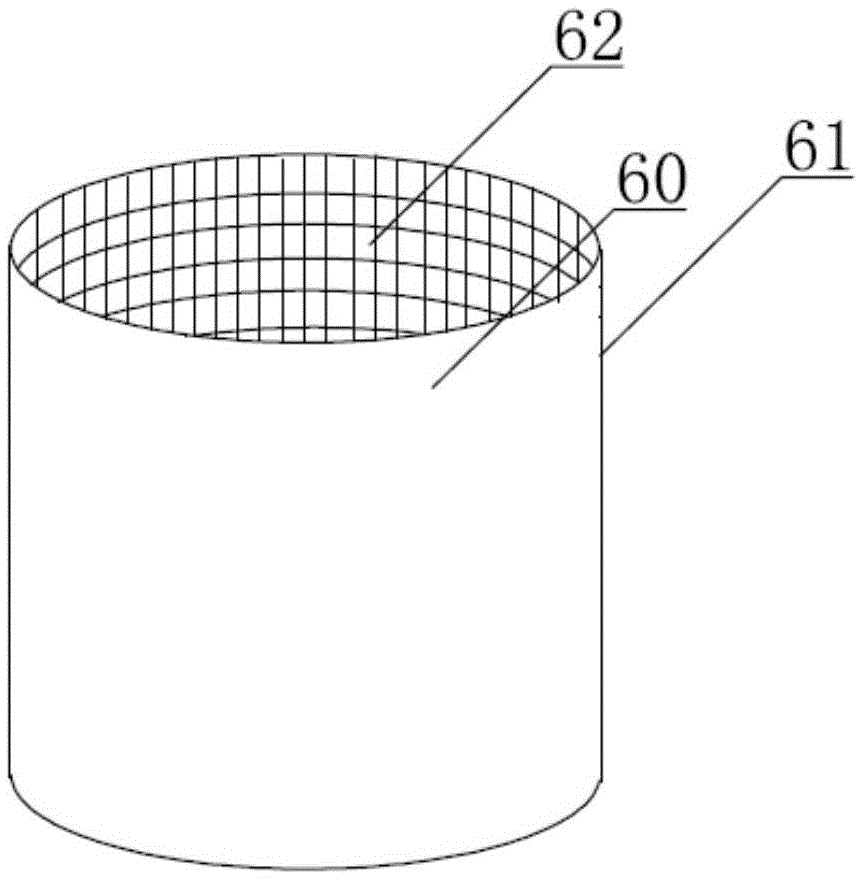

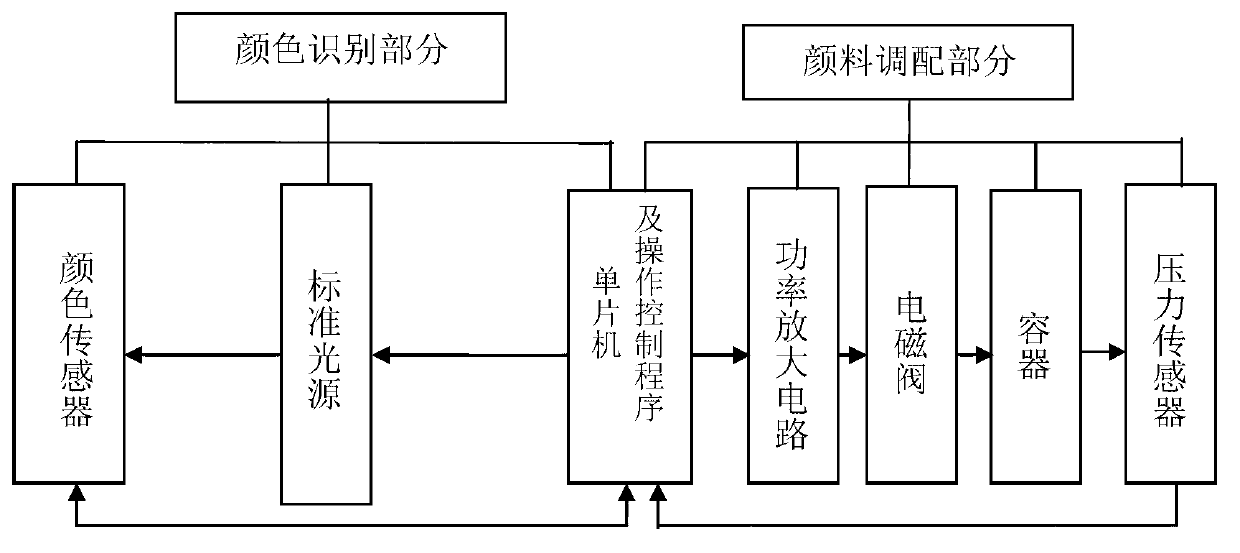

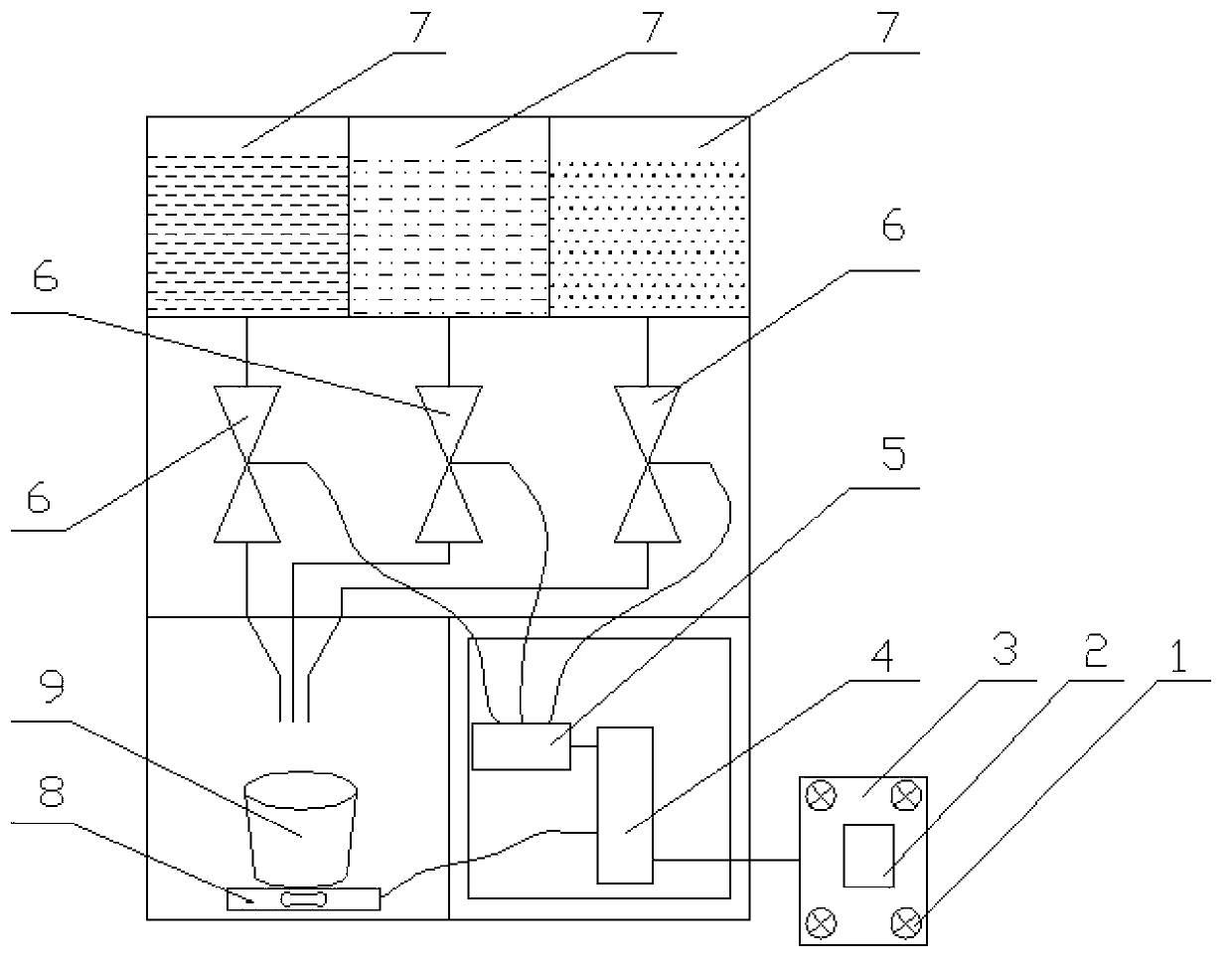

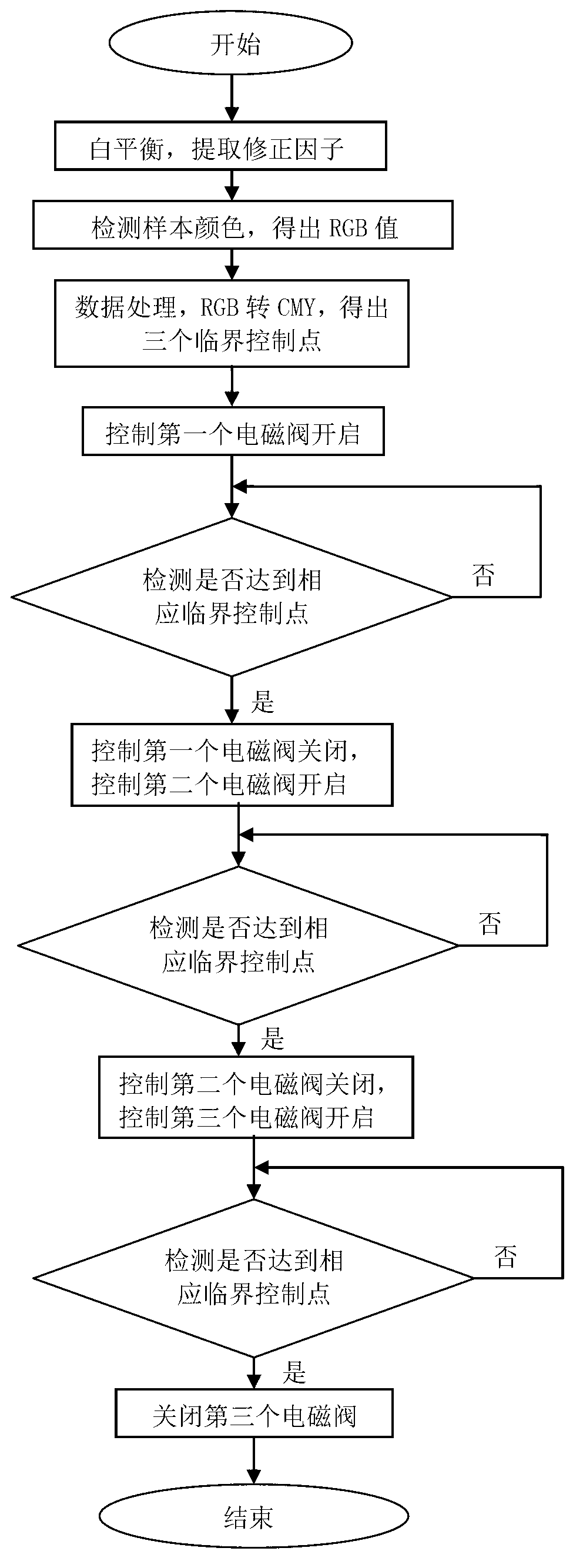

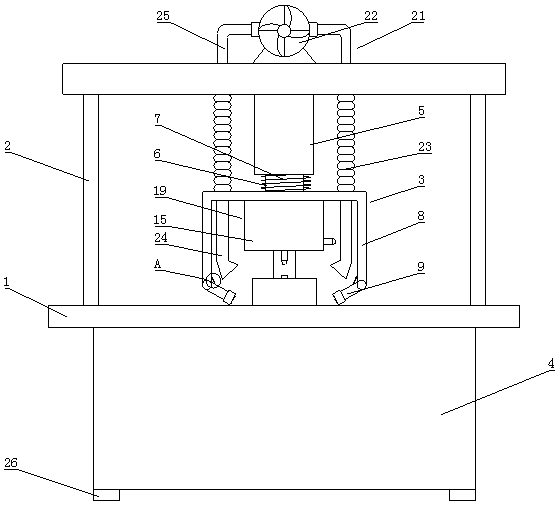

Automatic mixing device for pigment

ActiveCN103101393AFully automatedReduce human errorOther artistic work equipmentsColor recognitionMagnetic valve

The invention provides an automatic mixing device for pigment and relates to a device which is used for color combination. The automatic mixing device for the pigment comprises a color recognition portion and a color mixing portion, wherein the color recognition portion mainly comprises a standard light source, a color sensor, a single chip microcomputer and an operation control procedure. The single chip microcomputer is synchronously connected with the standard light source and the color sensor through lines, and the standard light source and the color sensor are arranged in a light shielding cover. The color mixing portion mainly comprises a single chip microcomputer, a power amplifying circuit, an electromagnet, a pressure sensor and a container. The single chip microcomputer is connected with the electromagnet through a power amplifying circuit, one end of the electromagnet is installed at the bottom of the container, and the other end of the electromagnet is provided with a pipeline which is guided out of the other end of the electromagnet. The pressure sensor is connected with the single chip microcomputer through lines, a round bucket which is used for containing mixed pigment is arranged on the pressure sensor, and the round bucket is arranged below the pipeline which is guided out of the other port of the electromagnet. The automatic mixing device for pigment overcomes the shortcomings that automatic recognition can not be achieved in the prior art in the color recognition process and precise color mixing rate in a color mixing link can hardly be achieved.

Owner:HEBEI UNIV OF TECH

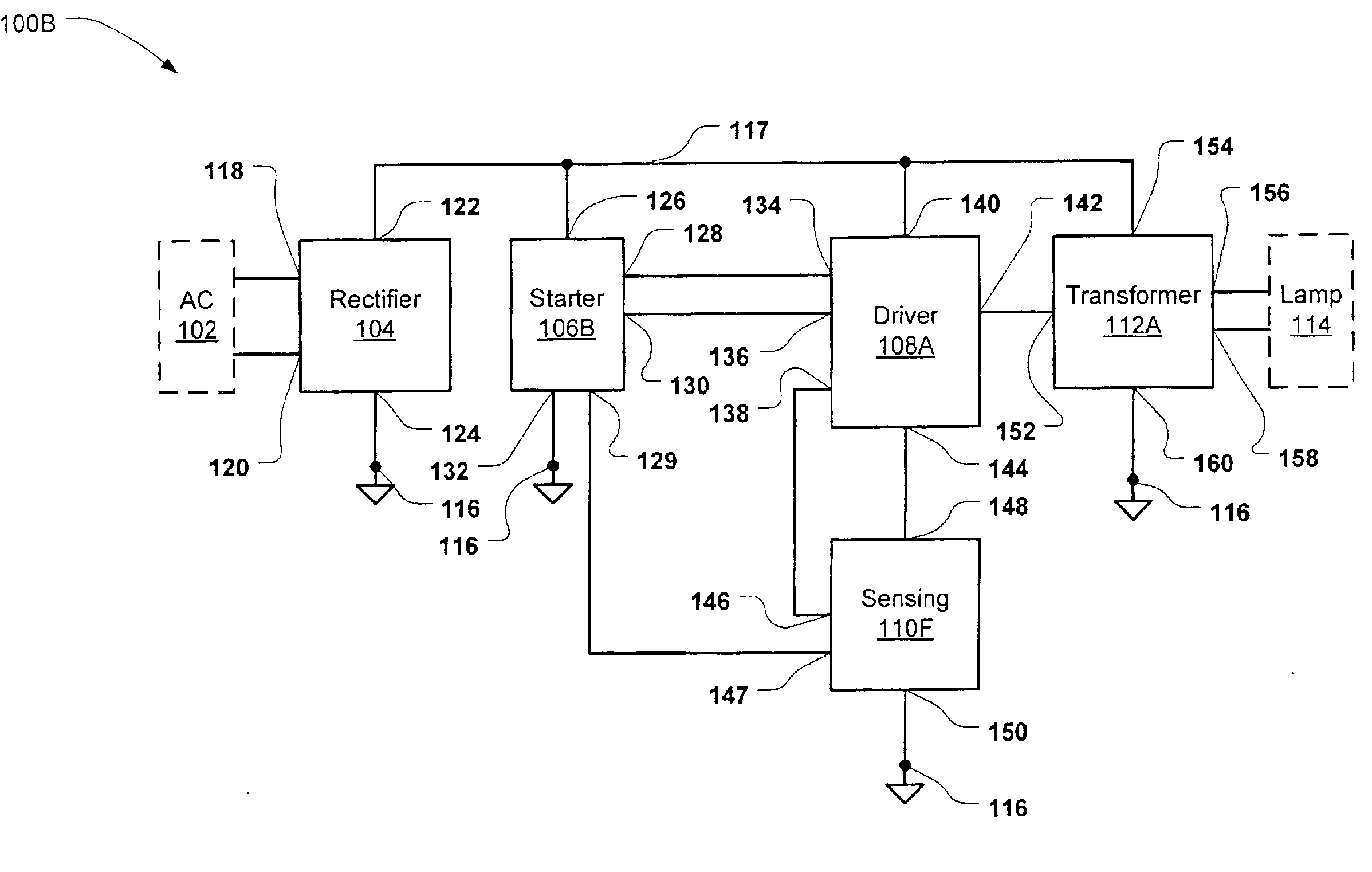

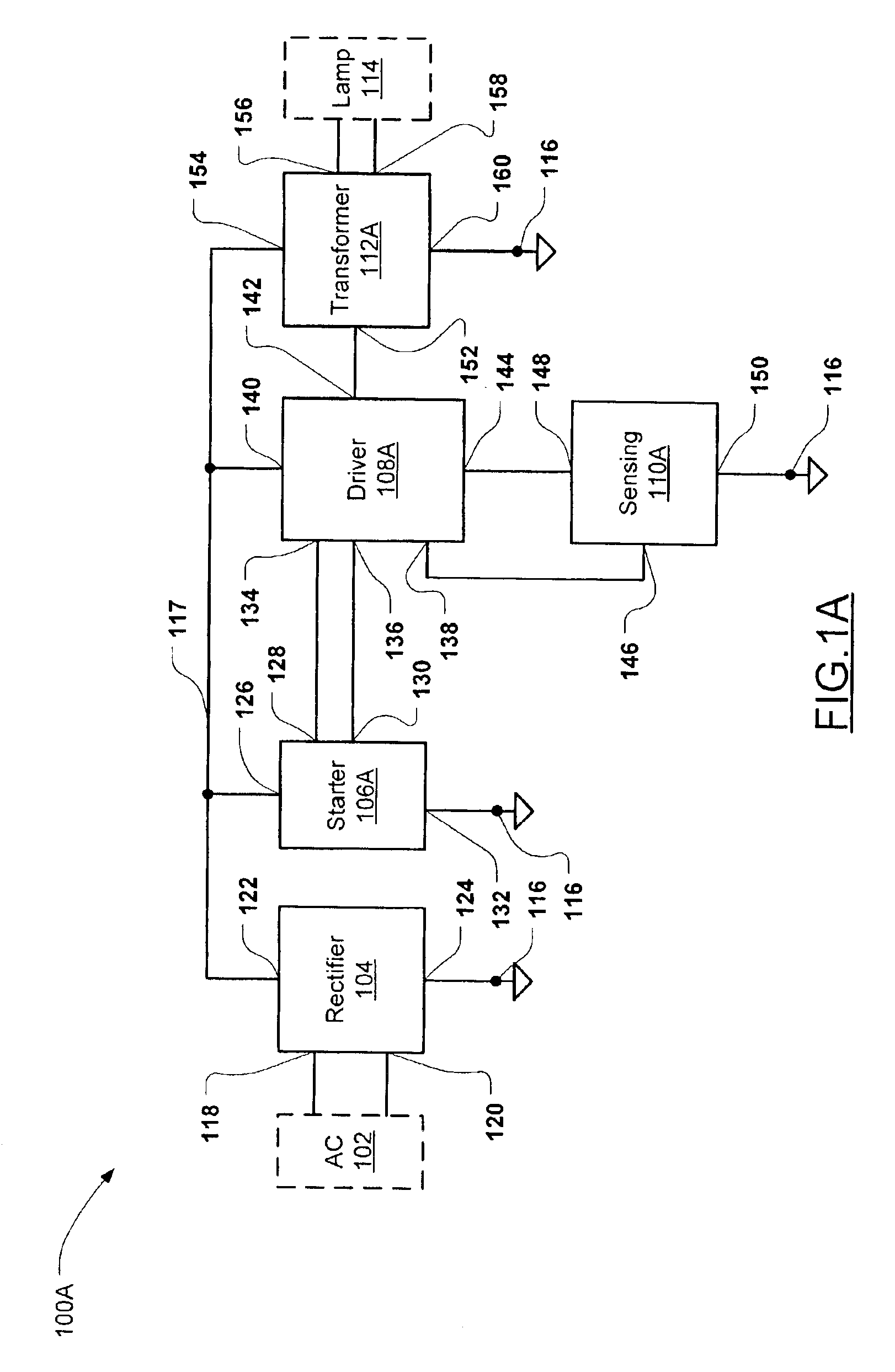

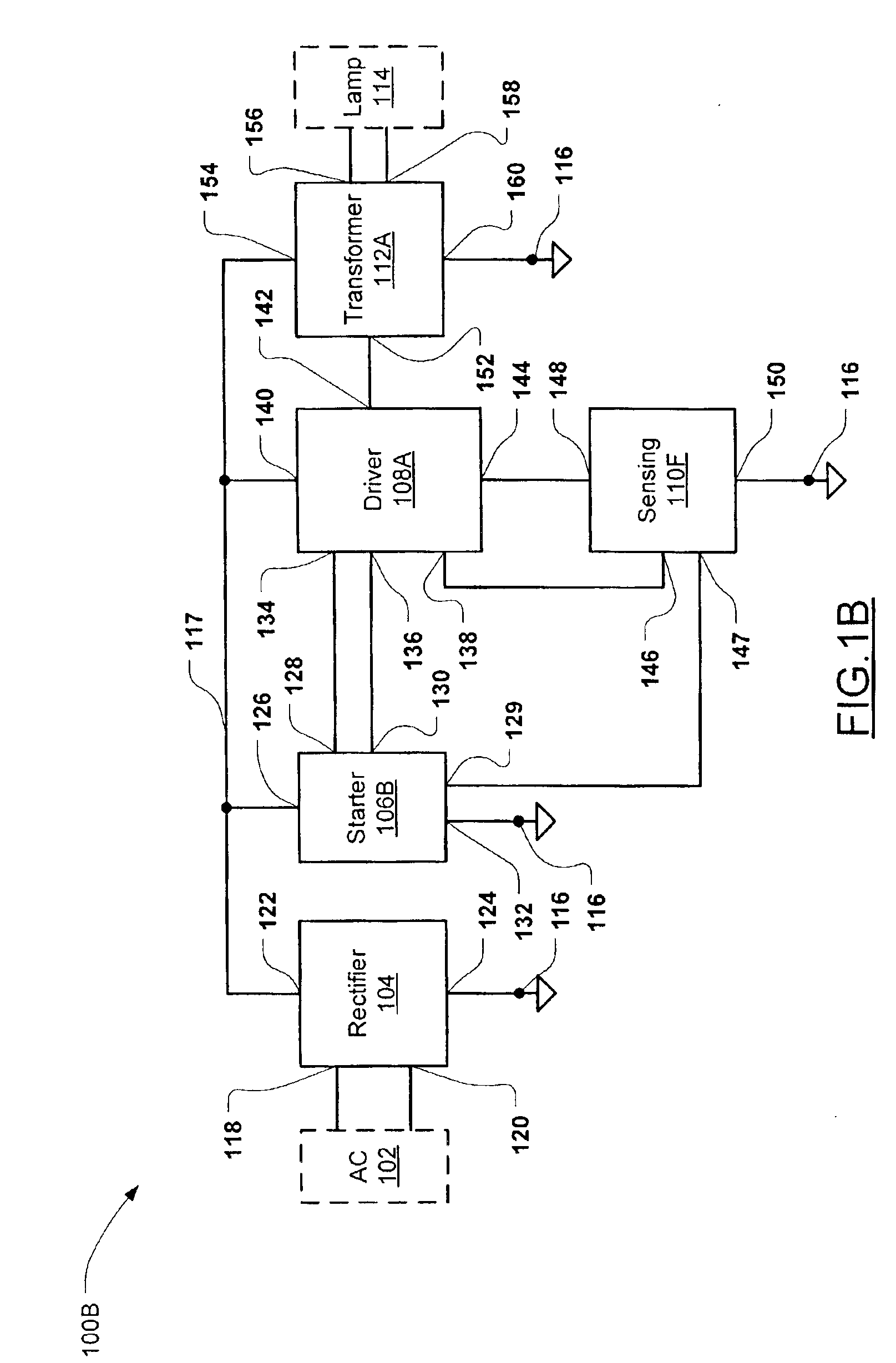

Converter for converting an AC power main voltage to a voltage suitable for driving a lamp

InactiveUS6856098B2Low costImprove reliabilityAc-dc conversionElectric light circuit arrangementDriver circuitDriving current

An electronic converter converts high-voltage AC power main voltage, such as 120V, 240V or 277V, to a low-voltage suitable for driving a halogen lamp. The converter includes a rectifier circuit, starter circuit, a driver circuit, a current sensing circuit and a transformer circuit with an optional synchronous output rectifier. The current sensing circuit senses an output current of the converter. The sensed current is used to govern pulse-width modulation of the lamp drive voltage, to provide over-voltage protection. Temperature protection can also be provided to reduce drive current when the converter overheats. This enables reliable operation of the converter over an extended temperature range, and reduces the occurrence of converter component failures due to ground faults or overheating.

Owner:ECLAIRAGE CONTRASTE M L

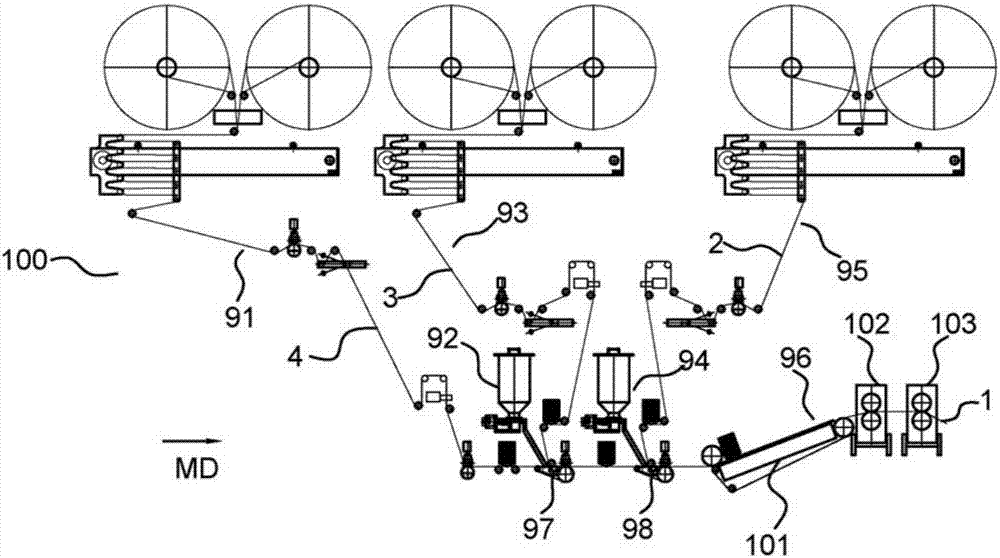

Manufacturing system and method for absorbing articles

ActiveCN107411886ALow costPromote Absorptive CapacityAbsorbent padsBaby linensTechnical supportAbsorption effect

The invention discloses a manufacturing system and method for absorbing articles. The system is provided with a first carrying unit, a second carrying unit, a first connecting workstation, a second water-absorbent particle adding device, a third carrying unit, a second connecting workstation and a first water-absorbent particle adding device. The problem that the traditional system difficultly meets requirements of on-line manufacturing of composite cores is solved. The method comprises the following processes of primary spreading, secondary spreading, edge folding, compacting, air discharging, dotting and compounding and the like. On-line manufacturing of composite cores is realized. The manufacturing system for absorbing articles has the advantages of low manufacturing cost and good absorbing effect. The gap in the field of on-line forming of composite cores is filled, and the technical support is provided for on-line production of the composite cores. The manufacturing system is simple in structure, accurate in control and high in production efficiency.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

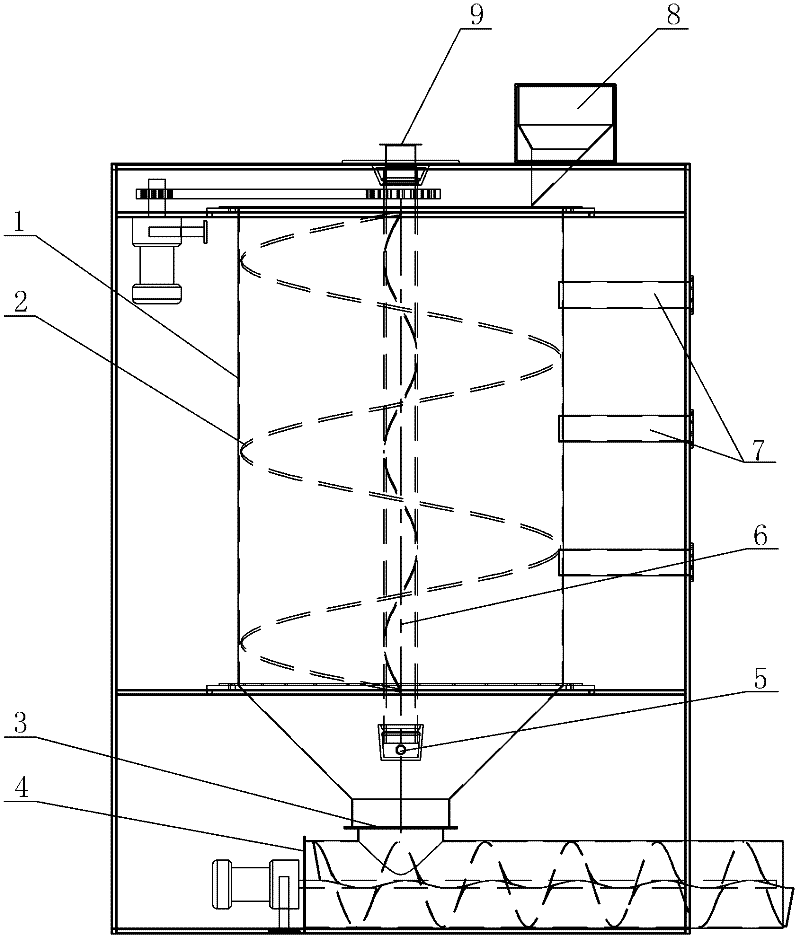

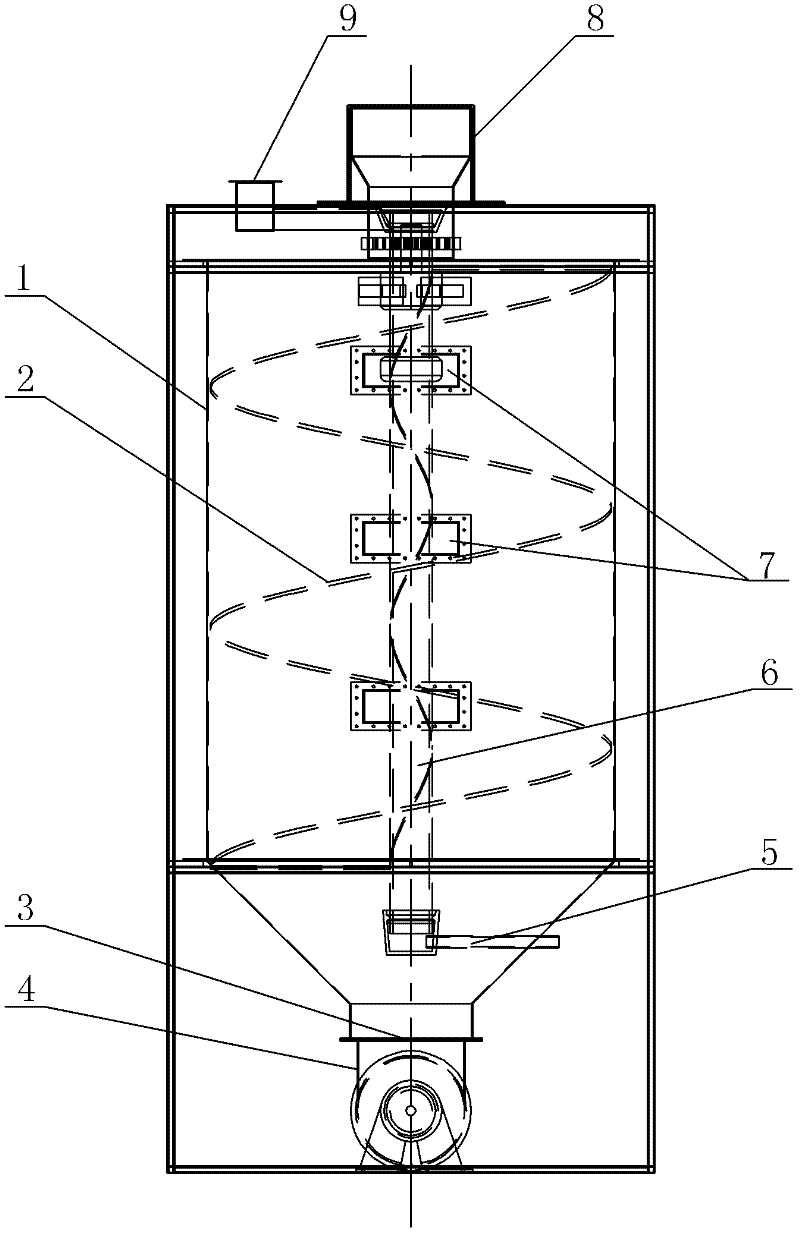

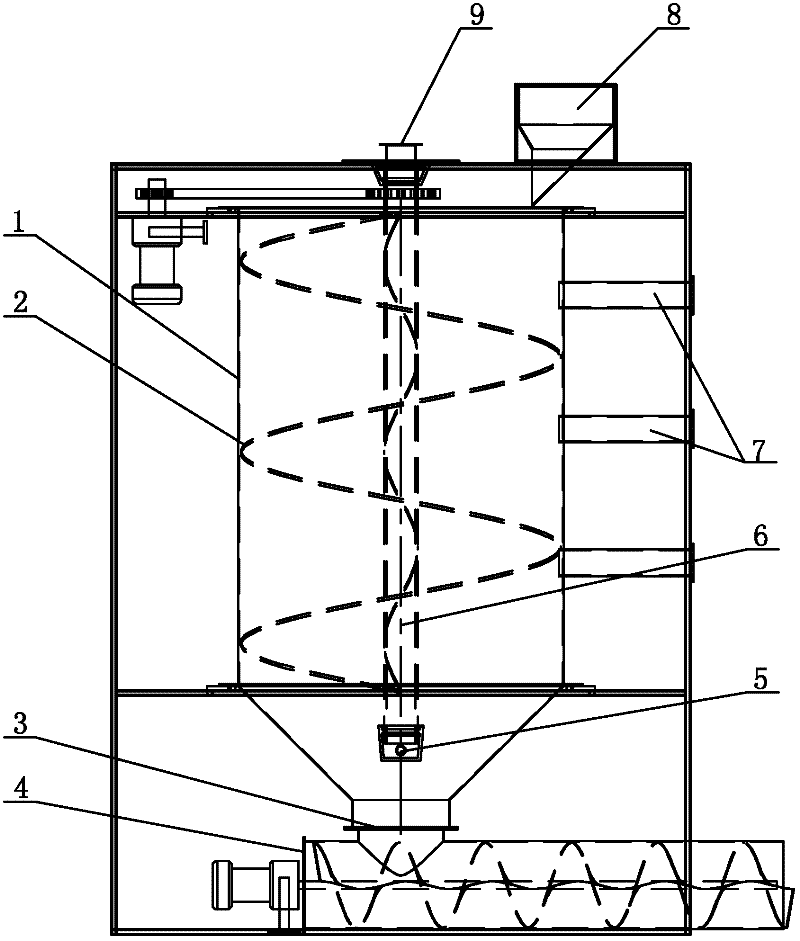

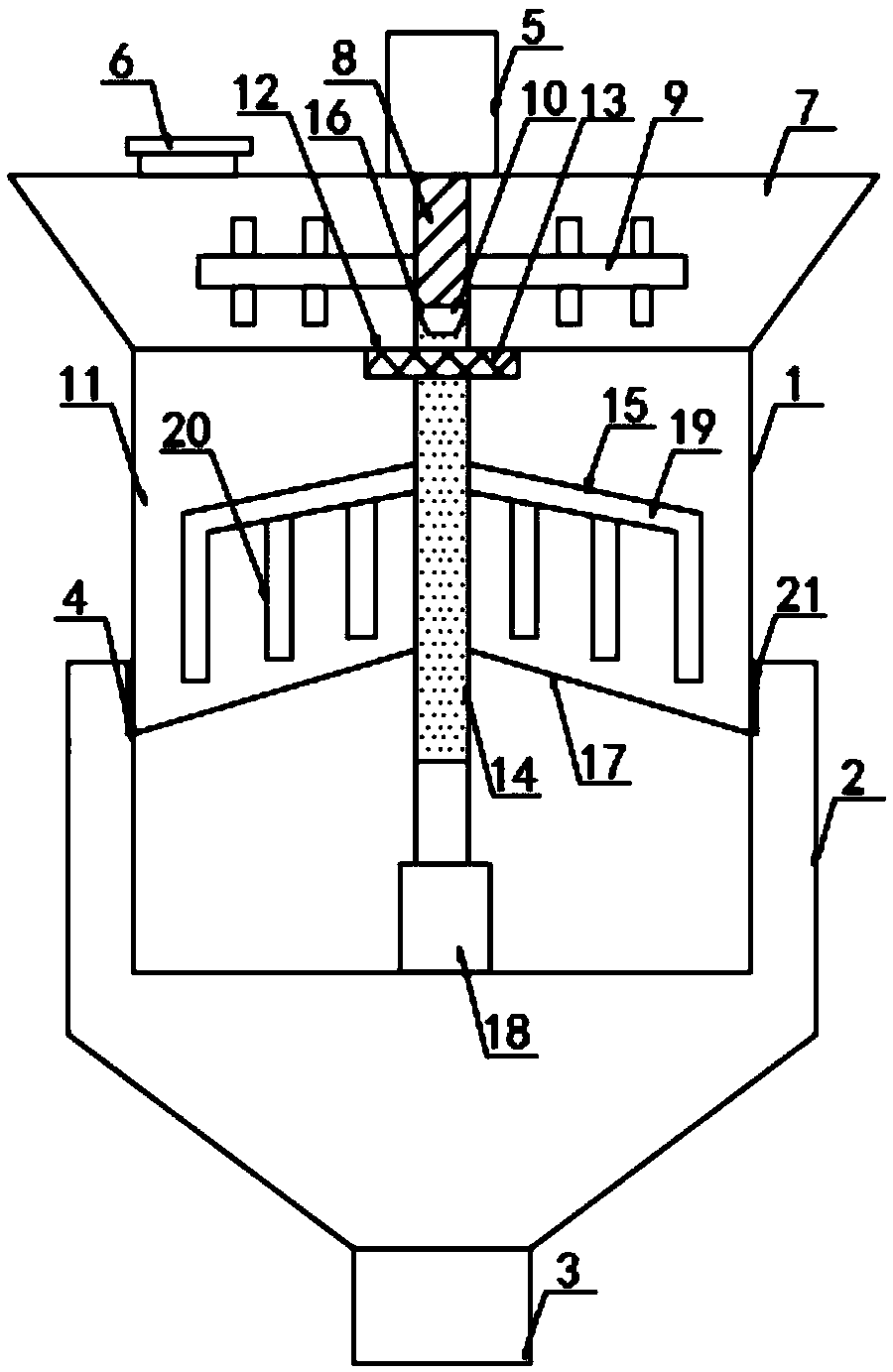

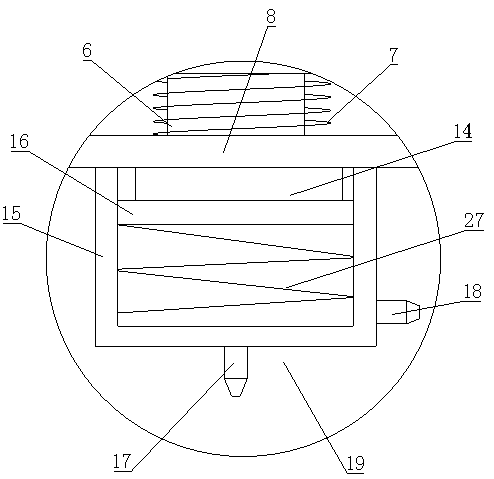

Vertical microwave drying coal furnace

InactiveCN102393132ADry evenlyPrecise output controlDrying solid materials with heatHearth type furnacesMicrowaveWater vapor

The invention belongs to the field of material drying equipment, in particular relates to a vertical microwave drying coal furnace which comprises a microwave drying furnace body, wherein a feeding hopper is arranged at the top end of the microwave drying furnace body; a waveguide duct for conducting microwaves is installed on the microwave drying furnace body; a ventilation pipeline is arranged in the microwave drying furnace body; a gas inlet of the ventilation pipeline is connected with high-pressure nitrogen gas filling equipment, and a gas outlet of the ventilation pipeline is communicated to the outside; the ventilation pipeline is drilled; and a discharge valve is arranged at a discharge opening at the bottom of the microwave drying furnace body. In the invention, a vertical structure is adopted, thus the floor space is small, the structure is simple, and the manufacturing cost is lowered; the microwave heating is adopted, thus the coal can be dried quickly and uniformly; the coal is used as a heating element, thus the heat utilization efficiency is high, the energy is saved, and the environment is protected; the high-pressure nitrogen gas filled in the ventilation pipeline forms negative pressure in the pipeline, and a through hole only absorbs water vapor evaporated from the coal, thus the clogging or microwave leakage is avoided; and a helical conveyer below the discharge opening can be used for accurately controlling the discharge quantity and discharge speed of the coal.

Owner:SHANDONG BO RUN IND TECH

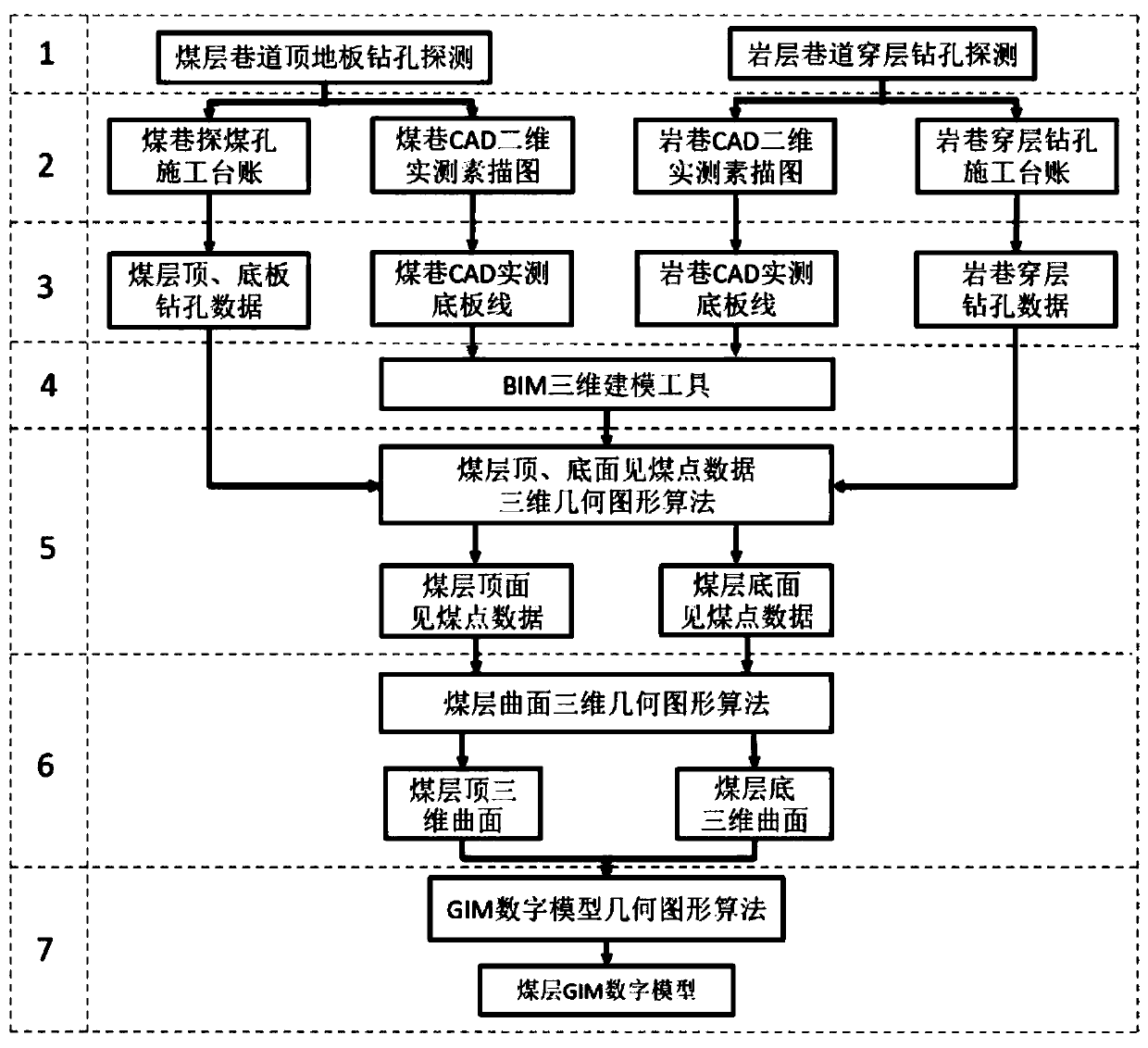

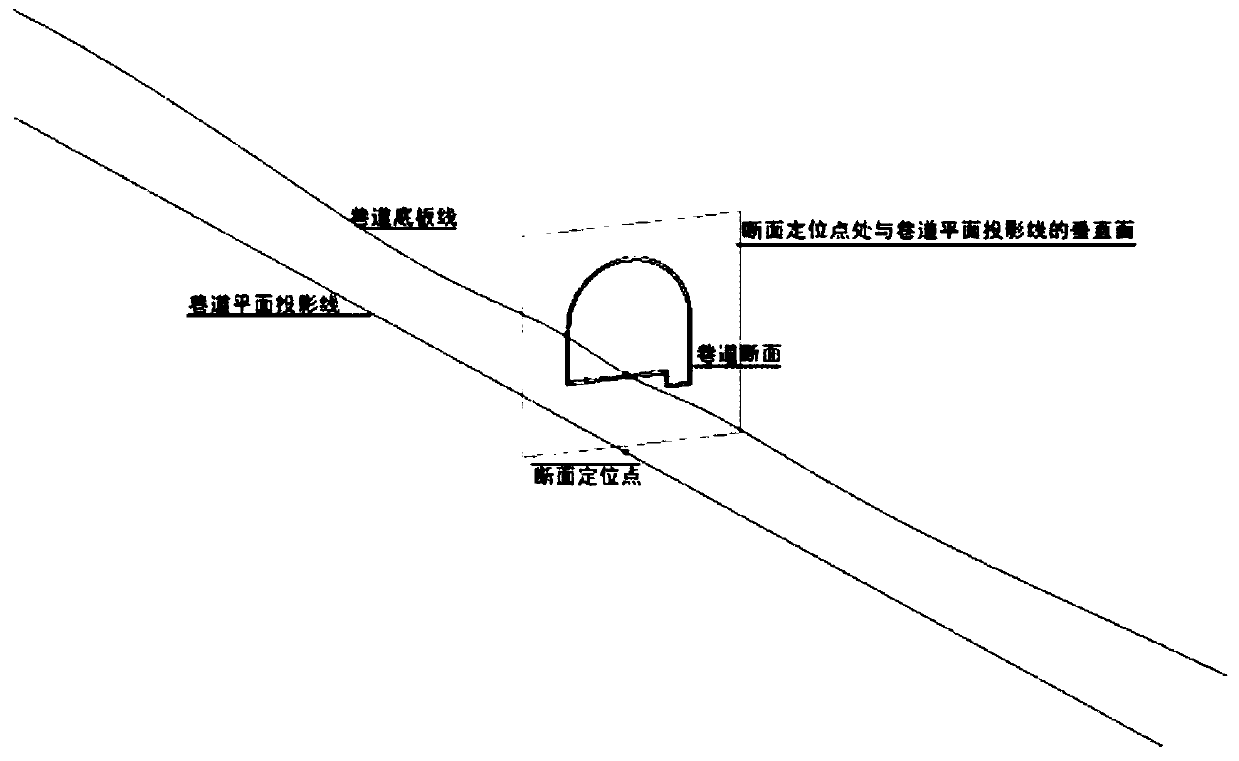

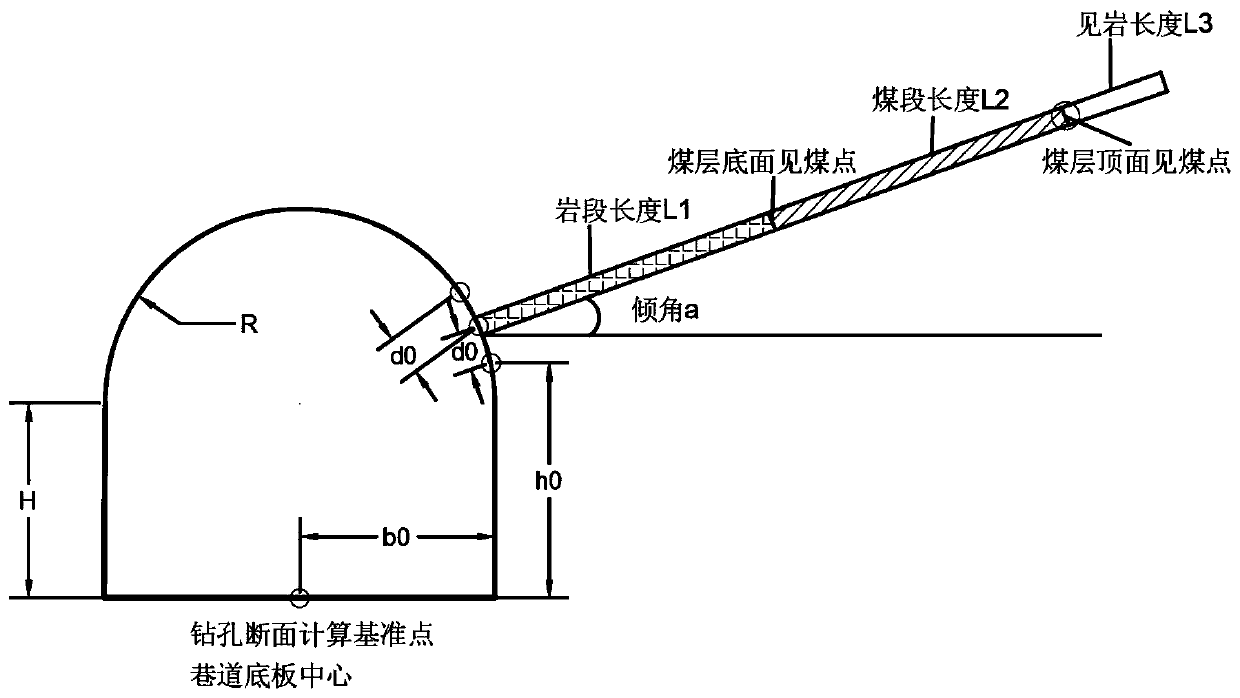

Coal mine working face coal seam GIM digital model creation method based on BIM

InactiveCN110245427APrecise output controlHigh precisionGeometric CADSpecial data processing applicationsStopped workComputer science

The invention provides a coal mine working face coal seam GIM digital model creation method based on BIM. The method includes: processing the field drilling actual measurement data; using a BIM modeling tool to edit three-dimensional geometric figure algorithm, creating a coal seam GIM digital model. The coal seam occurrence condition of the to-be-mined working face is accurately reflected; the technical defects of the existing two-dimensional CAD drawing technology are overcome; the problem that the coal seam occurrence condition cannot be visually and accurately checked before the coal mine is stoped on the working face is solved; the accuracy of coal mine production design management personnel for mastering the coal seam occurrence condition of the working face is improved, the coal yield of the working face is controlled more accurately, follow-up stoping work is guided to be carried out smoothly, and prevention and prejudgment on the disaster condition are achieved in advance.

Owner:华夏天信物联科技有限公司

Pneumatic impact system with digital display screen

InactiveCN102805888AAdjustable sizePrecise output controlIntravenous devicesHypodermoclysisImpact system

The invention discloses a pneumatic impact system with a digital display screen. The impact system can be used for providing an accurate high-pressure gas output amount through a pressure sensor, can be applied to a microjet injector for intradermic injection, hypodermic injection or muscle fluid injection, and can be applied to powder jet of solid powder.

Owner:张文芳

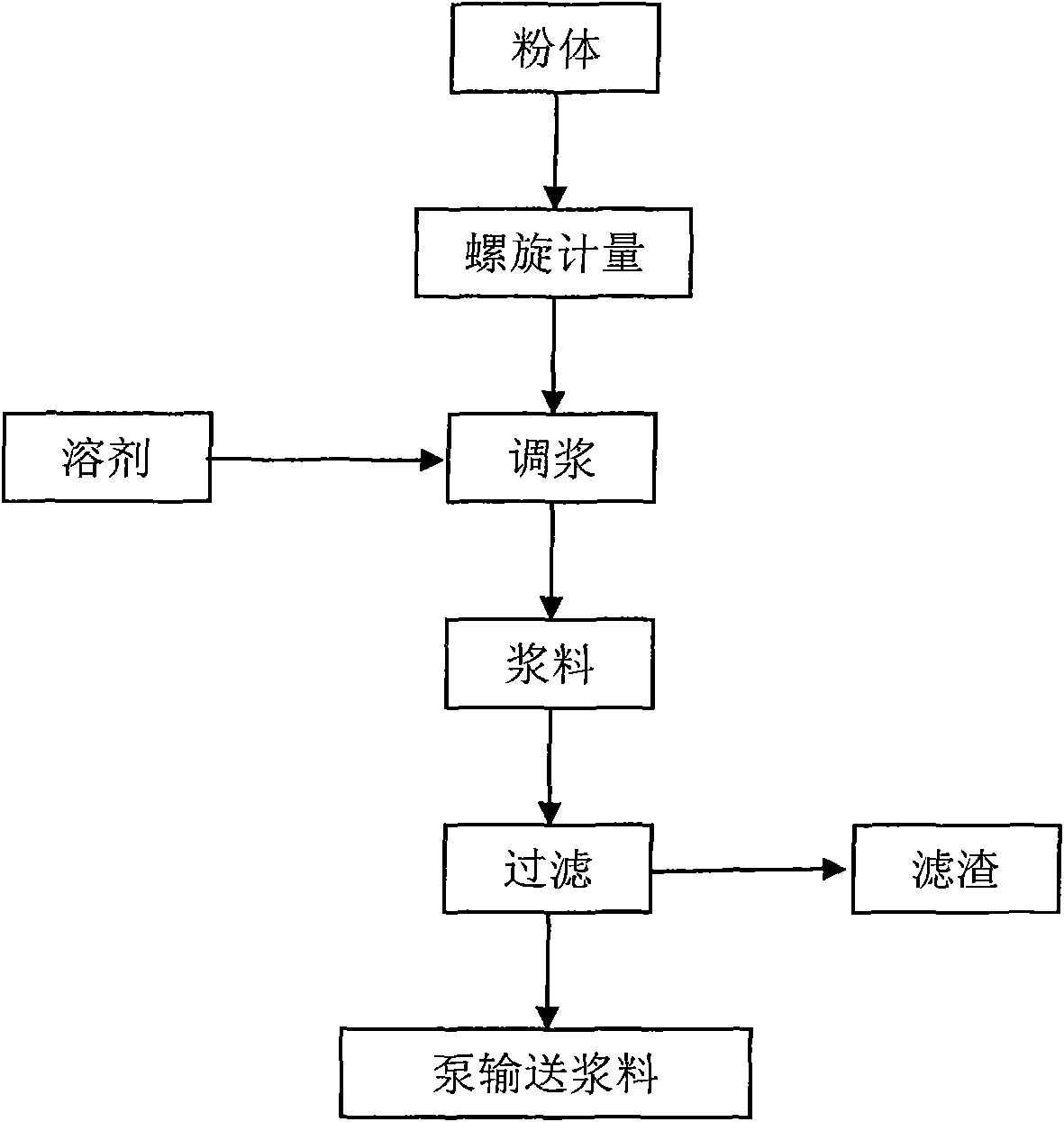

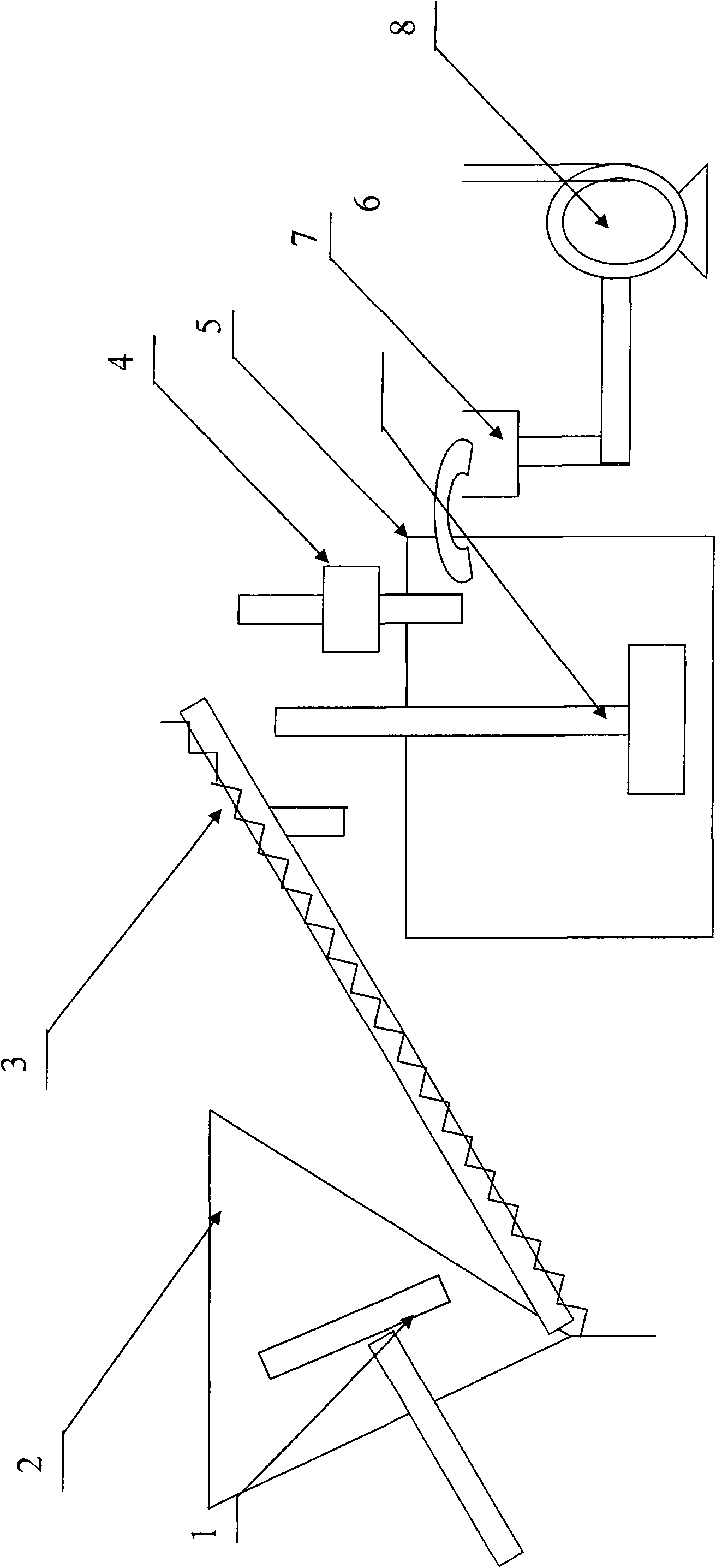

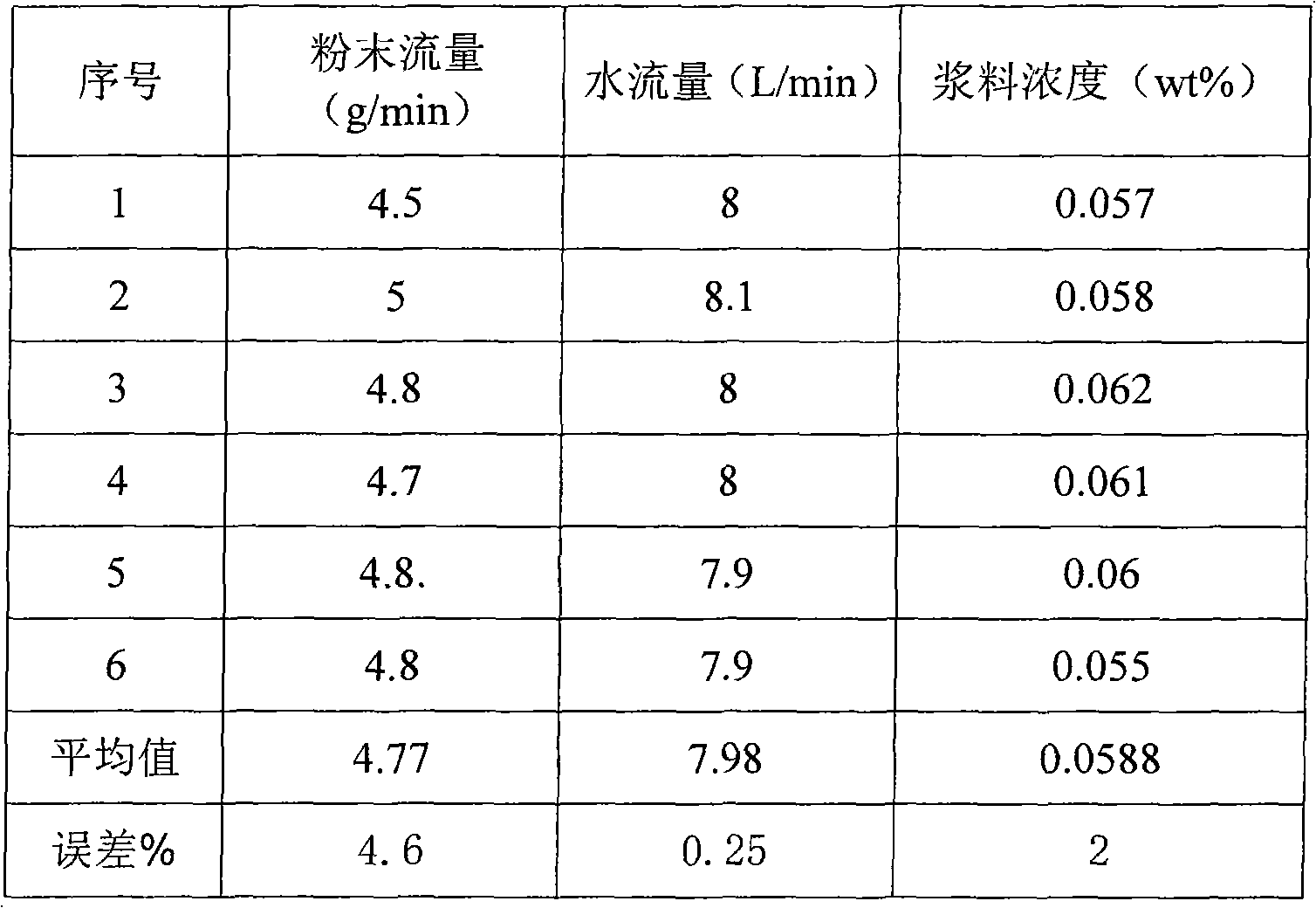

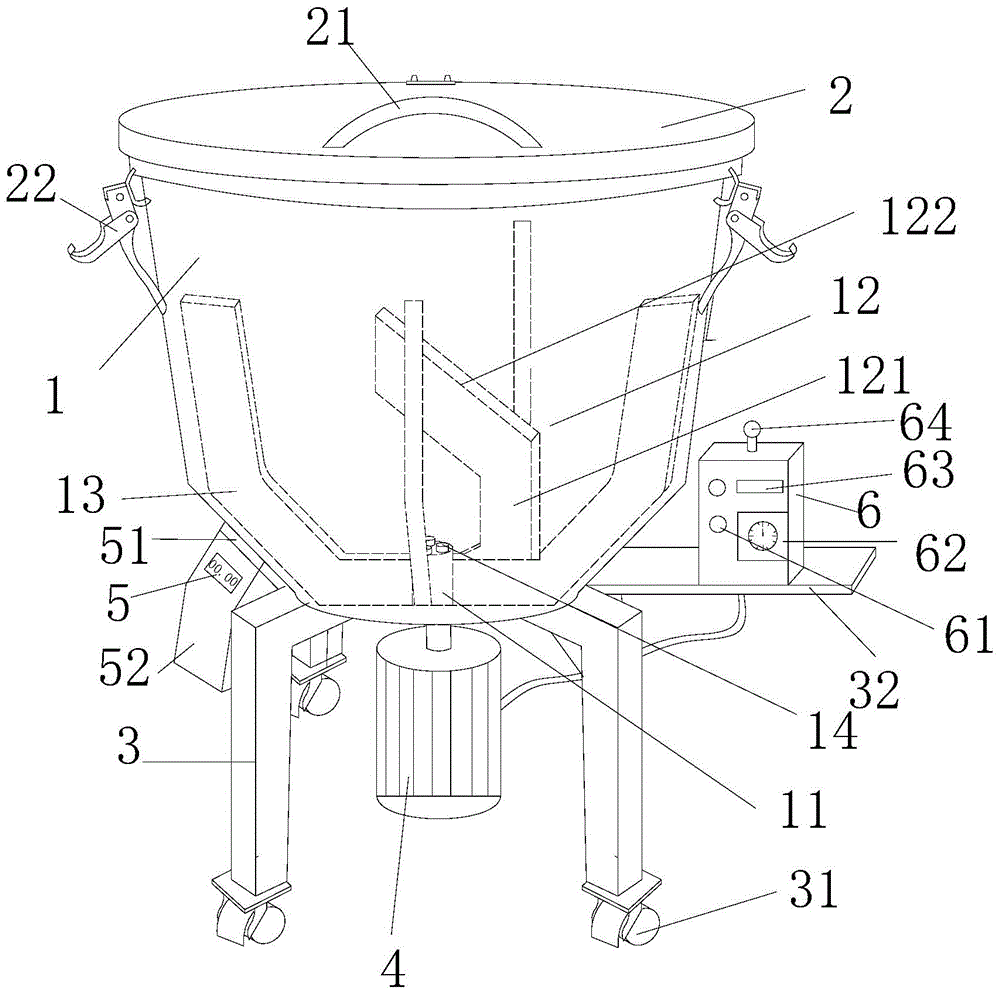

Quantitive slurry conveying equipment and method for conveying slurry

InactiveCN101993026APrevent subsidenceReduced precision requirementsRotary stirring mixersMixing methodsSpecific gravityLogistic management

The invention provides quantitive slurry conveying equipment and a method for conveying slurry. The equipment can convey the slurry with a fixed slurry concentration. The equipment comprises a slurry mixing barrel 4, a quantitive powder conveying device, a stirring device 5, a solution metering device 6 and a slurry conveying device. The method for applying the equipment to convey the slurry comprises the following steps of continuously conveying a powdery substance and a liquid medium into a slurry mixing device in a cocurrent flow mode; and utilizing a spiral feeding device to continuously and quantitively convey the powdery substance, utilizing a flowmeter to continuously and quantitively convey the liquid medium, stirring and mixing in the slurry mixing device to form suspended slurry, continuously overflowing and outputting, and conveying the suspended slurry to an application position through the slurry conveying device. The equipment and the slurry conveying method can quantitively and continuously convey the slurry, are suitable for conveying a solid substance which has larger bulk specific gravity variation and is difficult to accurately control on the output quantity by depending on simple spiral feeding equipment, can also quantitively and remotely convey the slurry and are convenient for logistics management and safety operation.

Owner:GRIREM ADVANCED MATERIALS CO LTD +1

Silicone 3D printer and printing method of silicone products

ActiveCN105643939BHigh precisionPrecise output controlManufacturing driving meansManufacturing heating elementsData informationComputer module

The invention provides a silica gel 3D printer and a silica gel product printing method. The silica gel printer comprises a frame, an X-axle slide module, a Y-axle slide module, a Z-axle slide module, a silica gel printing head and an air pressure adjusting module. A main control module is used for controlling the Z-axle slide module to drive a forming platform to change the position along a Z axle according to model data information of a silica gel product to be printed, controlling the X-axle slide module and the Y-axle slide module to drive the silica gel printing head to move along a predetermined path at a first predetermined speed, and controlling the air pressure adjusting module to adjust air pressure in the silica gel printing head so as to control the silica gel printing head to extrude out silica gel at a second predetermined speed. The silica gel printer has the beneficial effects of simple structure, low energy consumption and simple technological flow.

Owner:SHENZHEN ADVENTURE TECH CO LTD

Device for automatically outputting e-liquid and electronic cigarette

The invention relates to a device for automatically outputting e-liquid. The device comprises a shell, a driving part, a controller, a battery assembly, an e-liquid storage bin, a piston assembly, a fixing base and an ejector-pin-type one-way valve; the driving part and the controller are fixed in the shell; the driving part is electrically connected with the battery assembly; the driving part isconnected to the piston assembly; the controller is electrically connected with the driving part and controls the driving part to drive the piston assembly to move in the e-liquid storage bin in the axis direction of the piston assembly; the e-liquid storage bin is located in the shell and provided with an e-liquid inlet and an e-liquid outlet; the fixing base is fixed to the top of the shell andlocated at the top of the e-liquid storage bin; a through hole is formed in the middle of the fixing base and internally provided with the ejector-pin-type one-way valve; the ejector-pin-type one-wayvalve can be converted to be communicated with or close the e-liquid outlet of the e-liquid storage bin. The invention further provides an electronic cigarette. By means of the device for automatically outputting the e-liquid, the output amount of the e-liquid can be controlled, and the electronic cigarette is prevented from e-liquid leakage at the same time.

Owner:蒋双峰

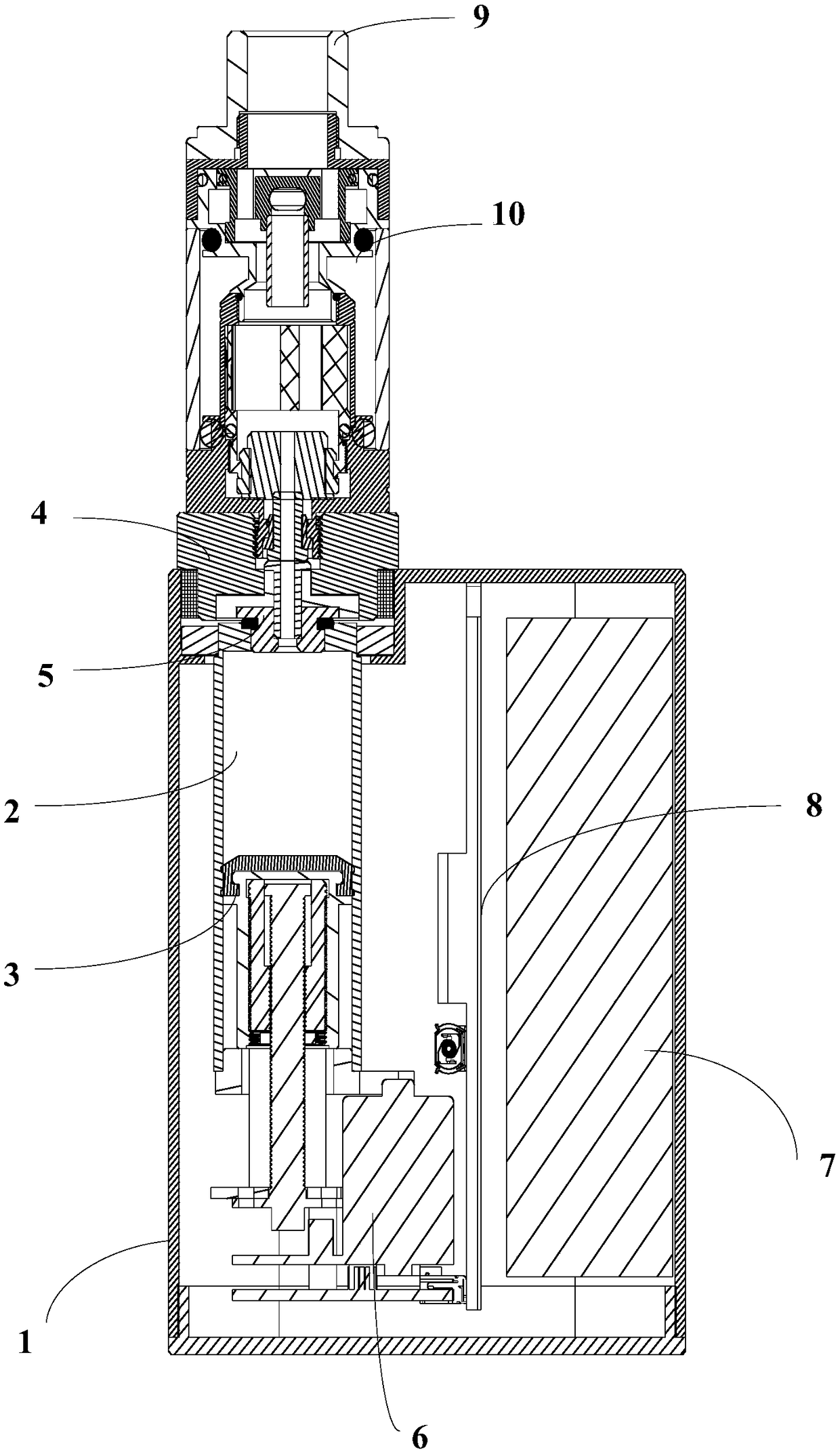

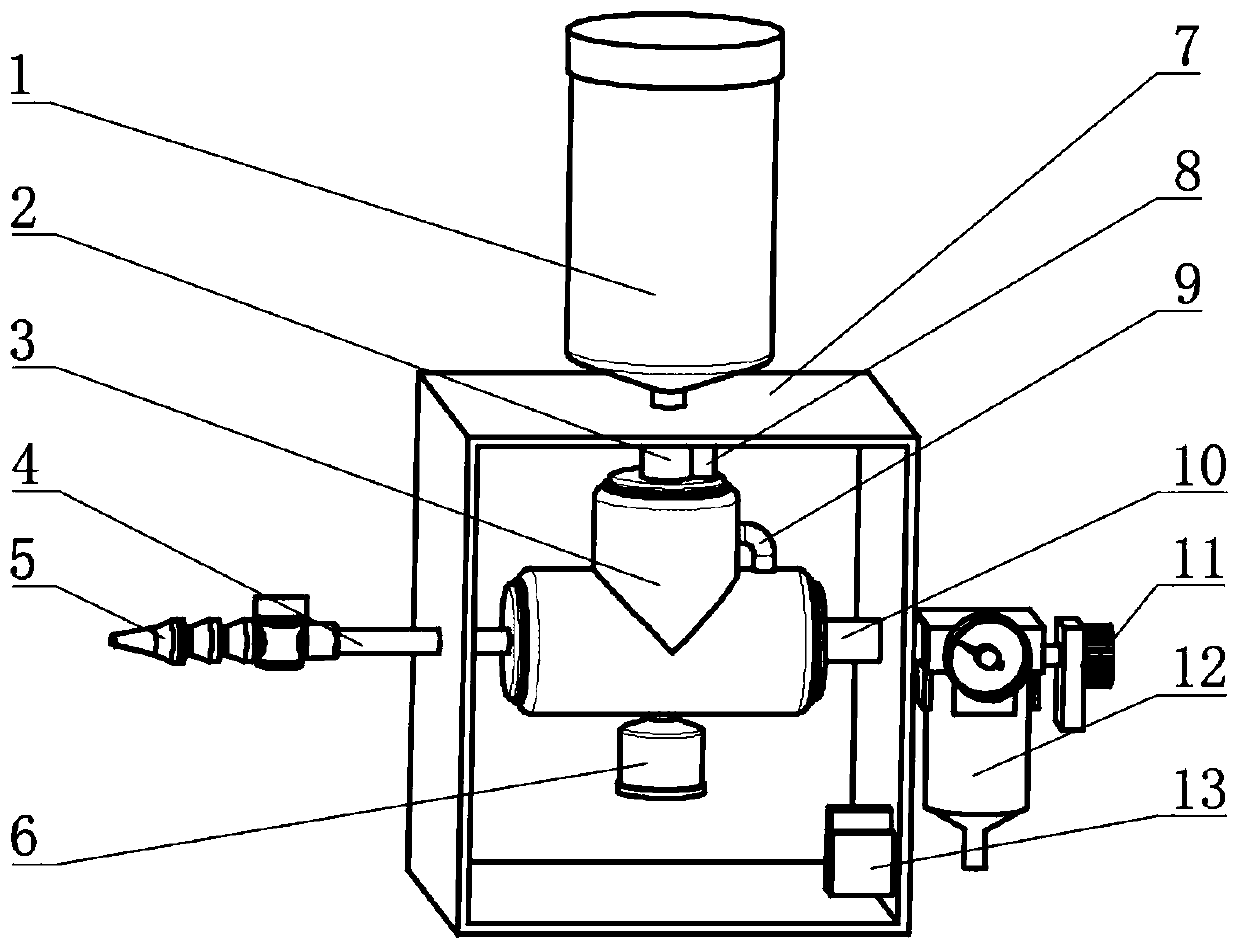

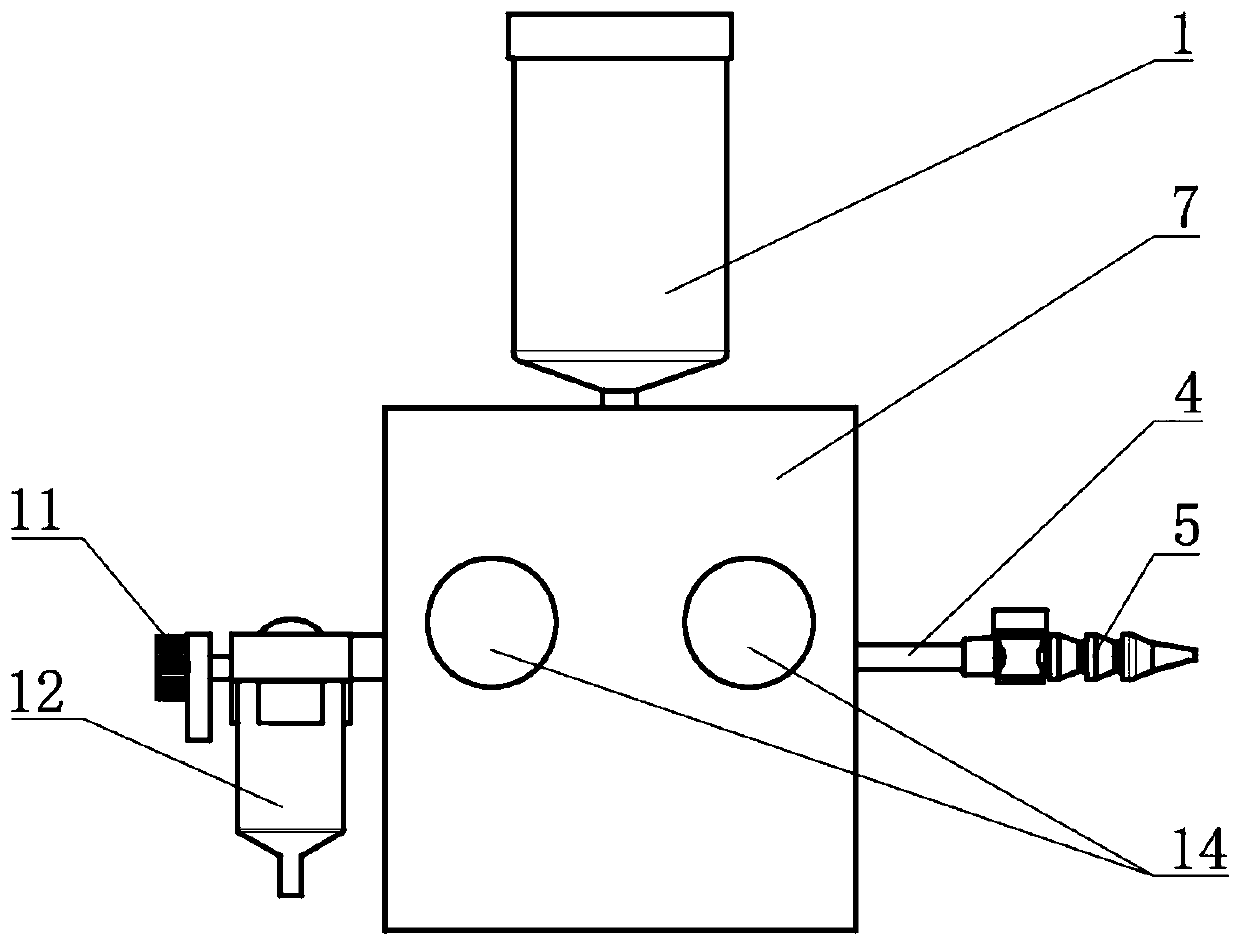

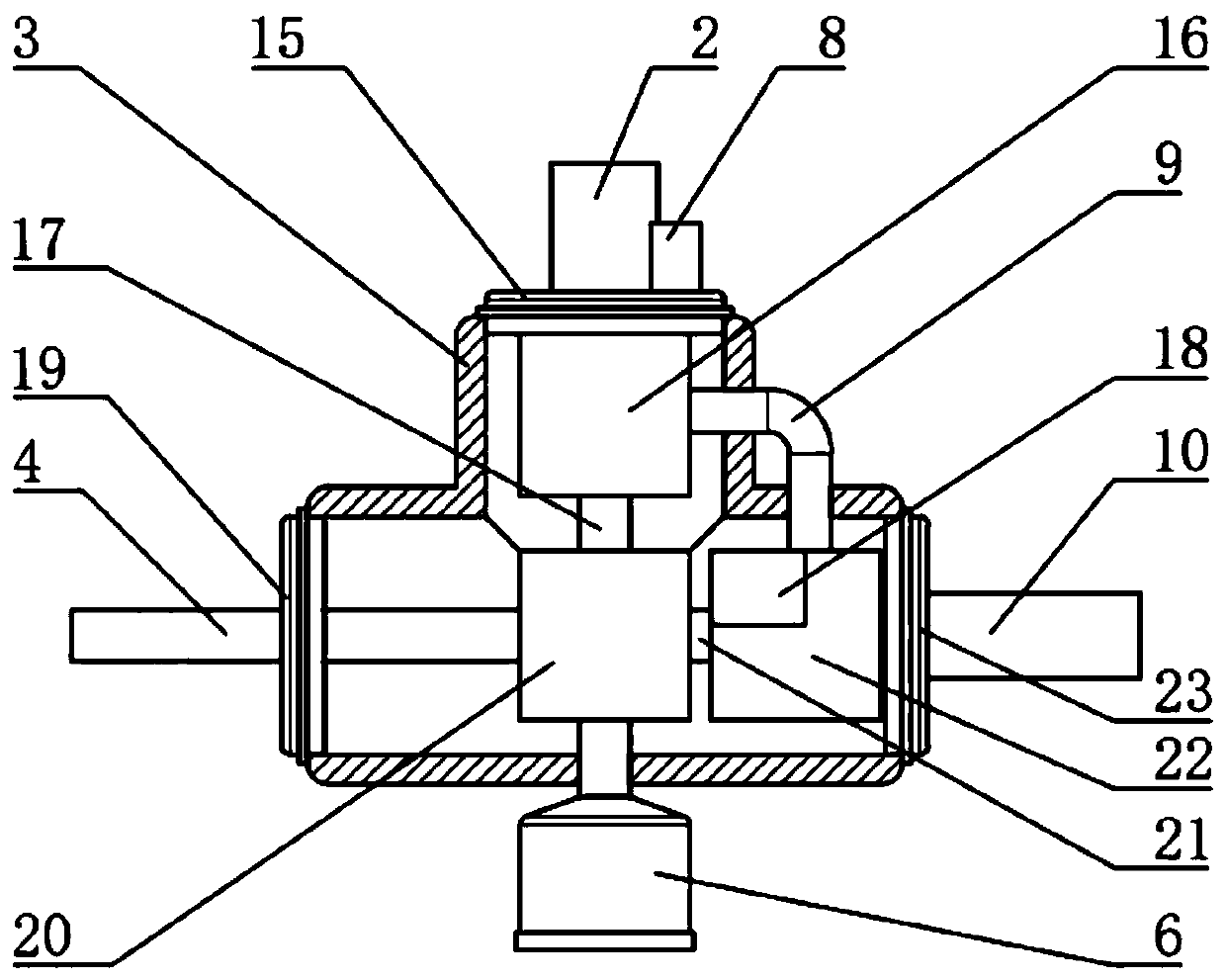

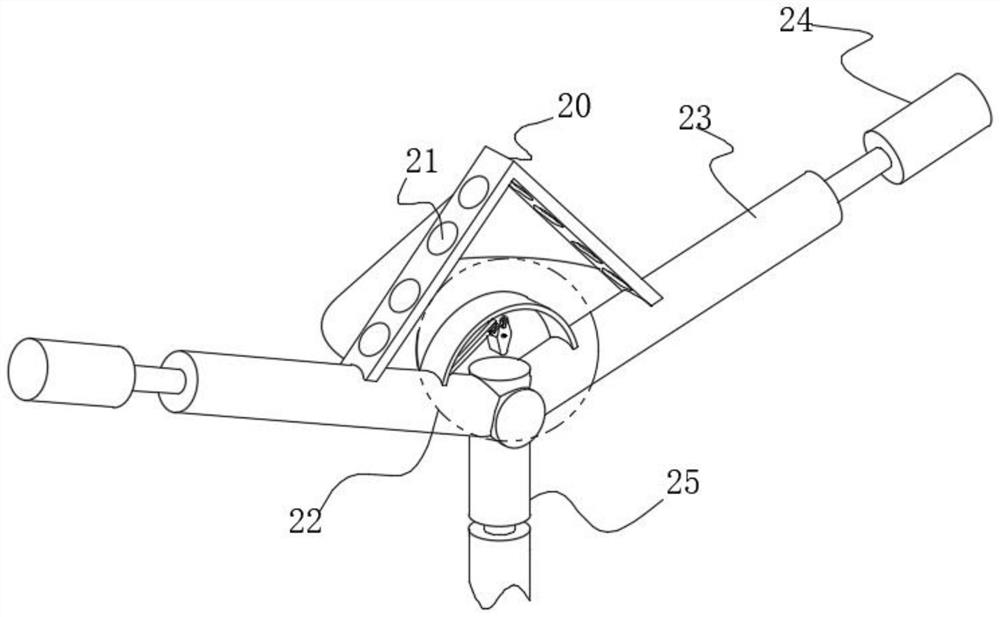

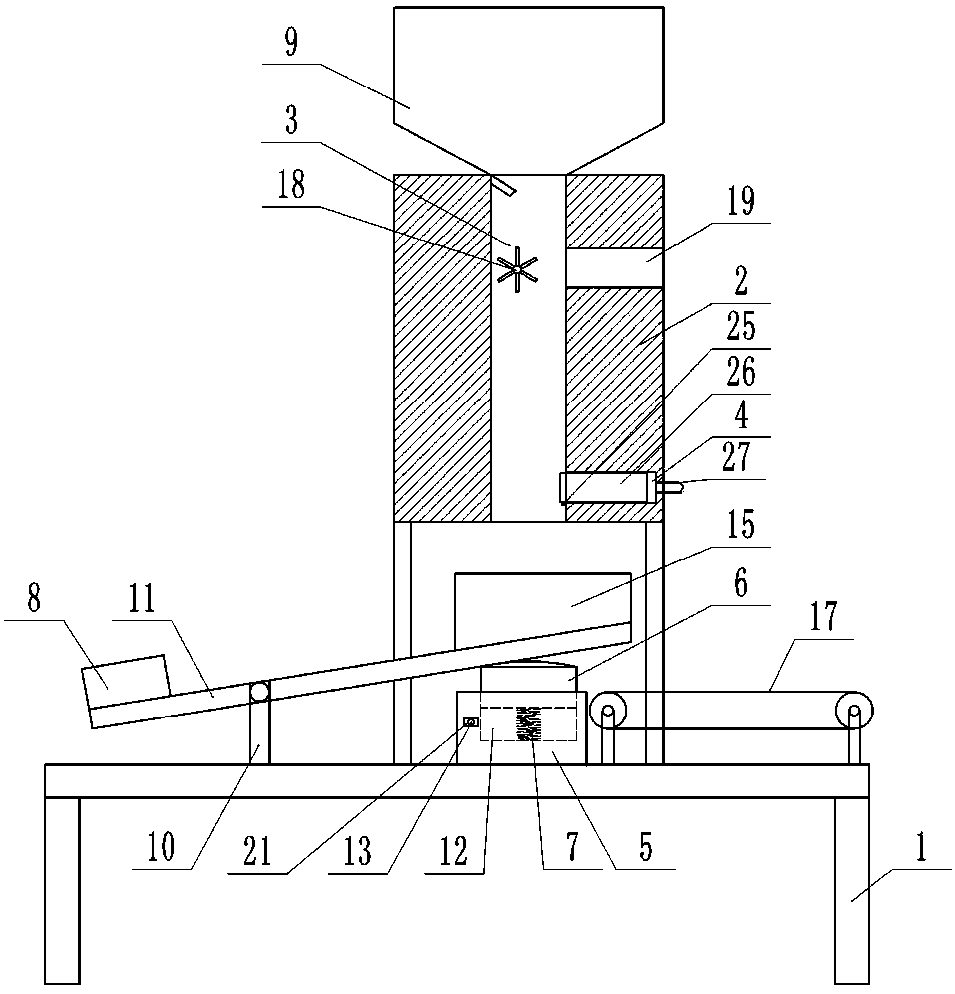

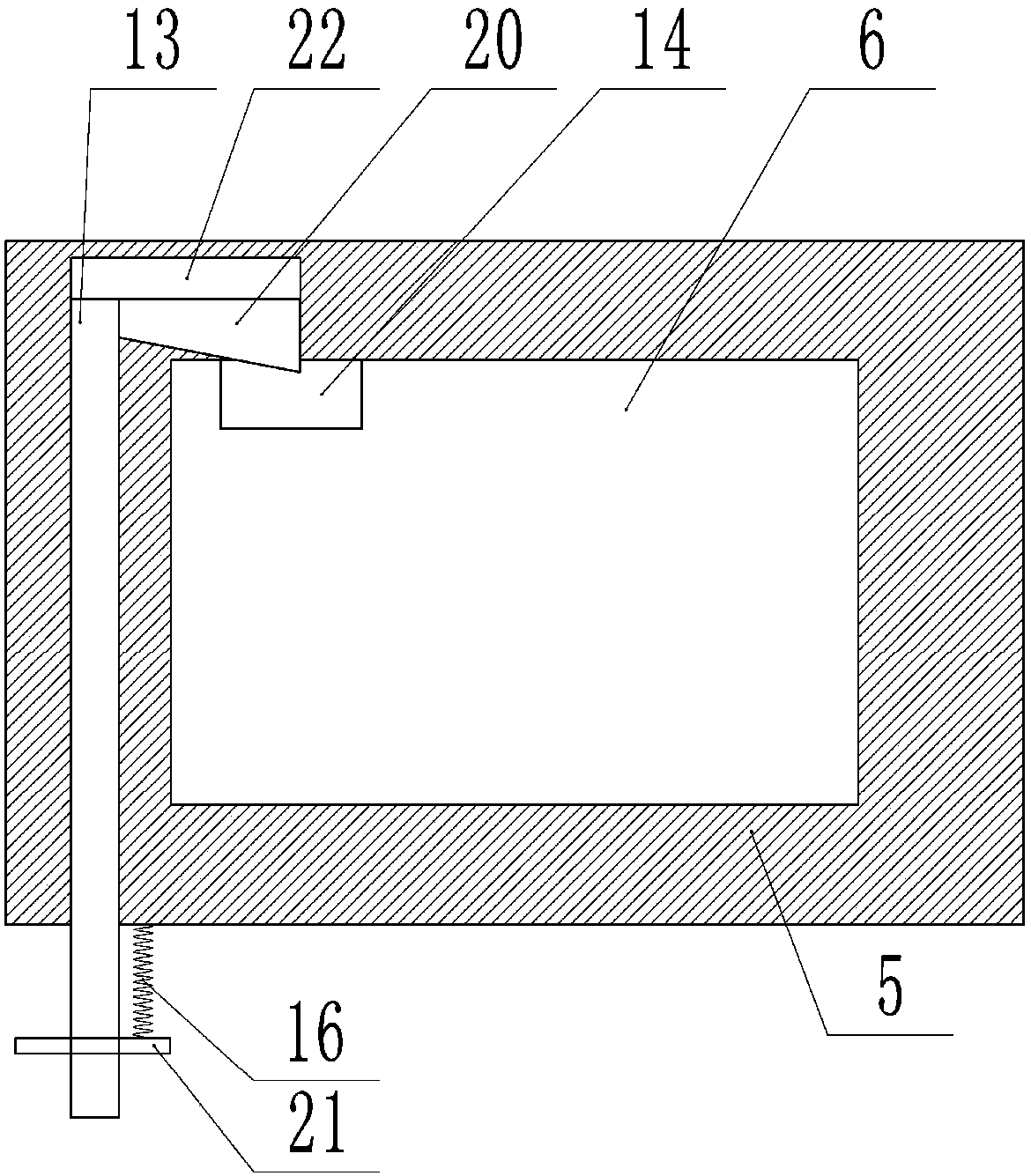

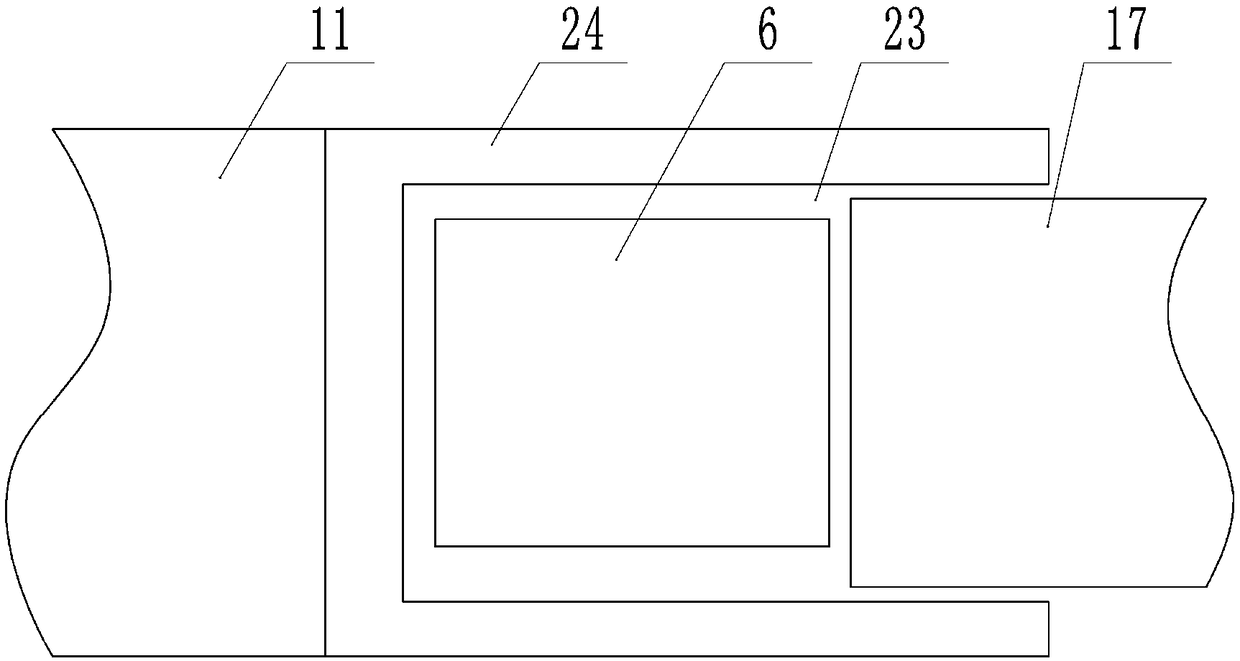

Micro lubricating device and using method thereof

ActiveCN109731705AControl outputPrecise output controlLiquid spraying apparatusSpray nozzleEngineering

The invention relates to a micro lubricating device and a using method thereof. The device comprises a box body (7) as well as an oil supply mechanism, a gas supply mechanism and a spray nozzle (5), which are arranged outside the box body (7). The micro lubricating device is characterized in that a secondary atomizing integrated pump (3) is arranged in the box body (7), wherein the oil supply mechanism, the gas supply mechanism and the spray nozzle (5) communicate with the secondary atomizing integrated pump (3); and after being mixed and atomized in the secondary atomizing integrated pump (3), oil and gas are spray out through the spray nozzle (5). Compared with the prior art, the micro lubricating device can improve lubricating performance of an oil-gas mixture, processing performance isfurther improved, production cost is reduced, the structure is simple, operation is convenient, and mounting and maintaining are easy.

Owner:SHANGHAI UNIV OF ENG SCI

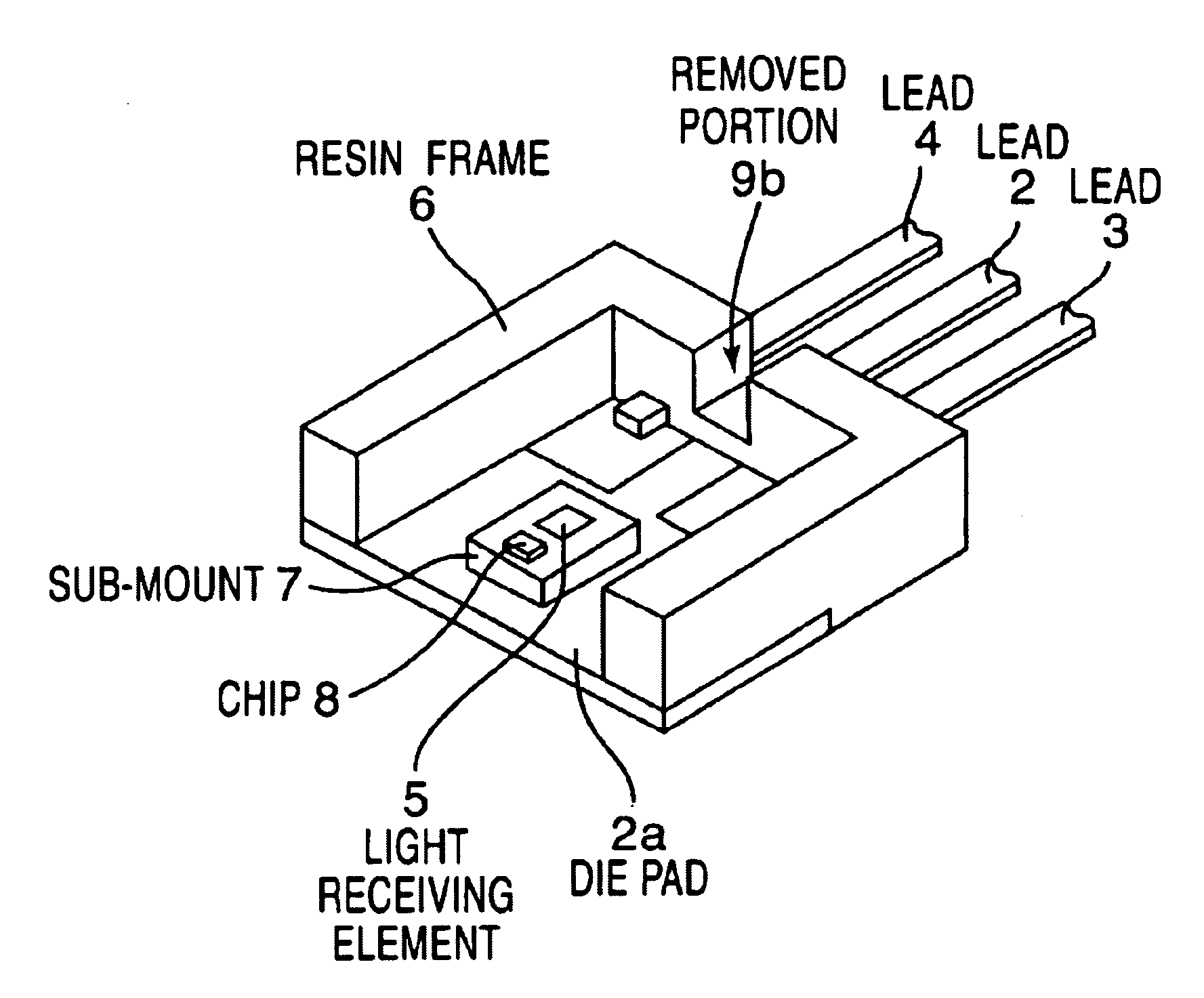

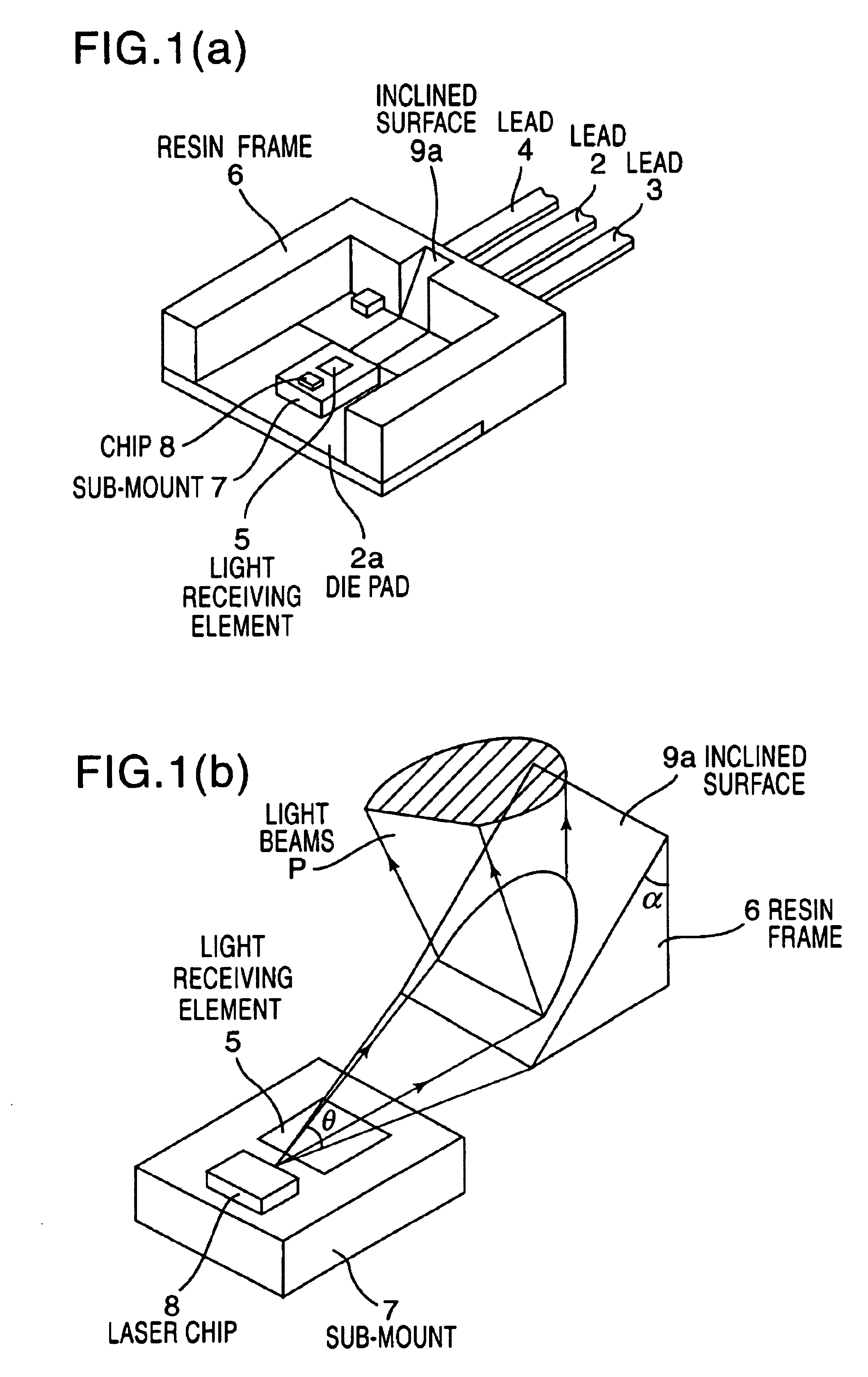

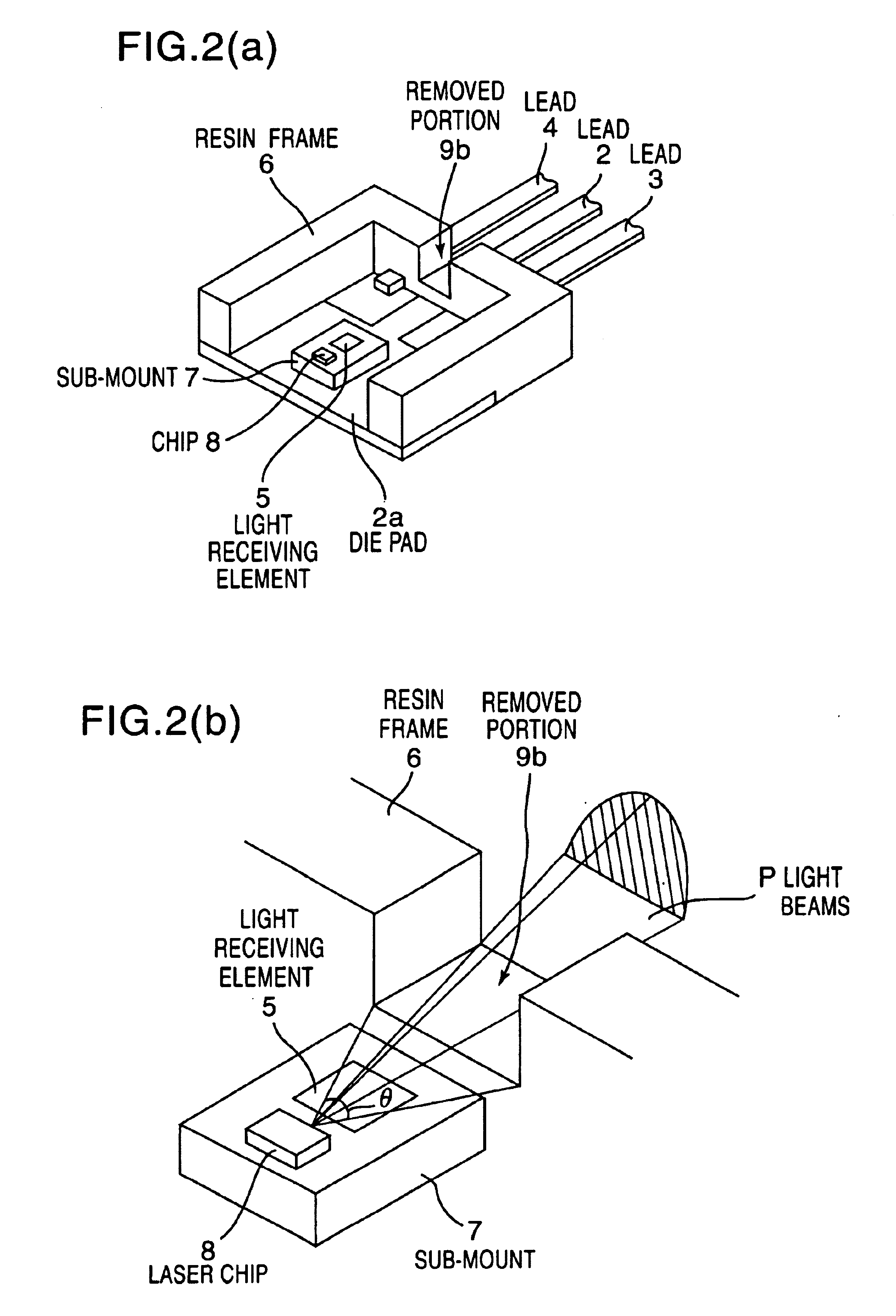

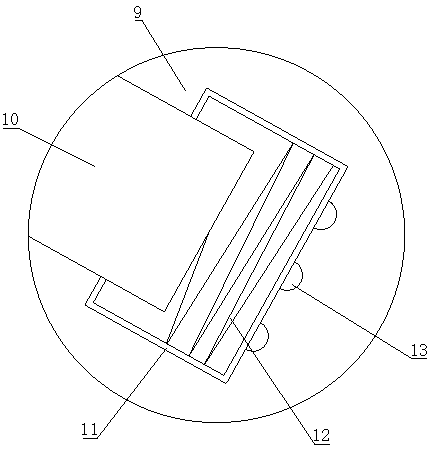

Mold type semiconductor laser

InactiveUS6970486B2Precise output controlEliminate variationLaser active region structureOptical beam sourcesElectricityEngineering

A sub-mount (7) provided with a laser chip (8) and a light receiving element (5) for monitoring is bonded to a die pad portion (2a) of a first lead (2). An electrode of the laser chip and an electrode of the light receiving element are electrically connected to second leads (3, 4) by wires such as metallic wires, not shown, respectively. A resin frame (6) is provided to cover sides and a rear surface side of the sub-mount except for an emission surface side of the laser chip and to integrally hold one end portion sides of the first and second leads. An antireflection unit (9) for preventing light from being reflected on the light receiving element is formed on a portion of the resin frame opposite to the rear end face of the laser chip. As a result, it is possible to obtain a mold type semiconductor laser capable of constantly detect accurate laser chip output and capable of forming an accurate optical output control circuit.

Owner:ROHM CO LTD

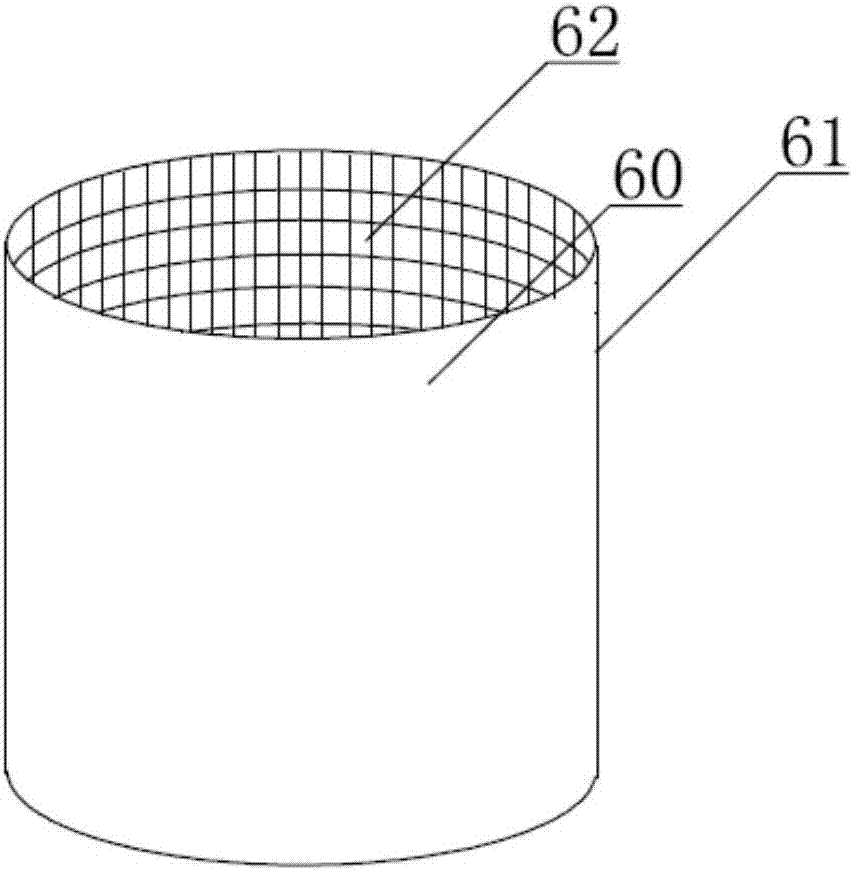

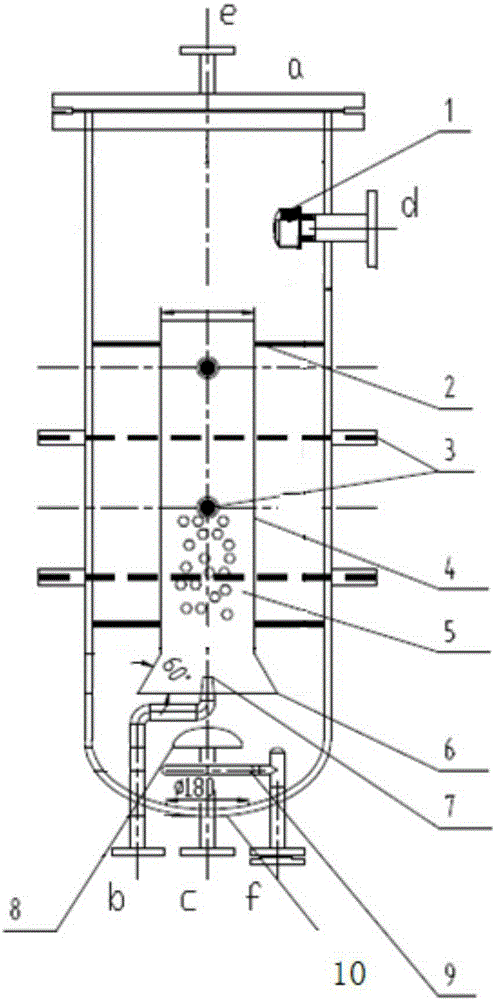

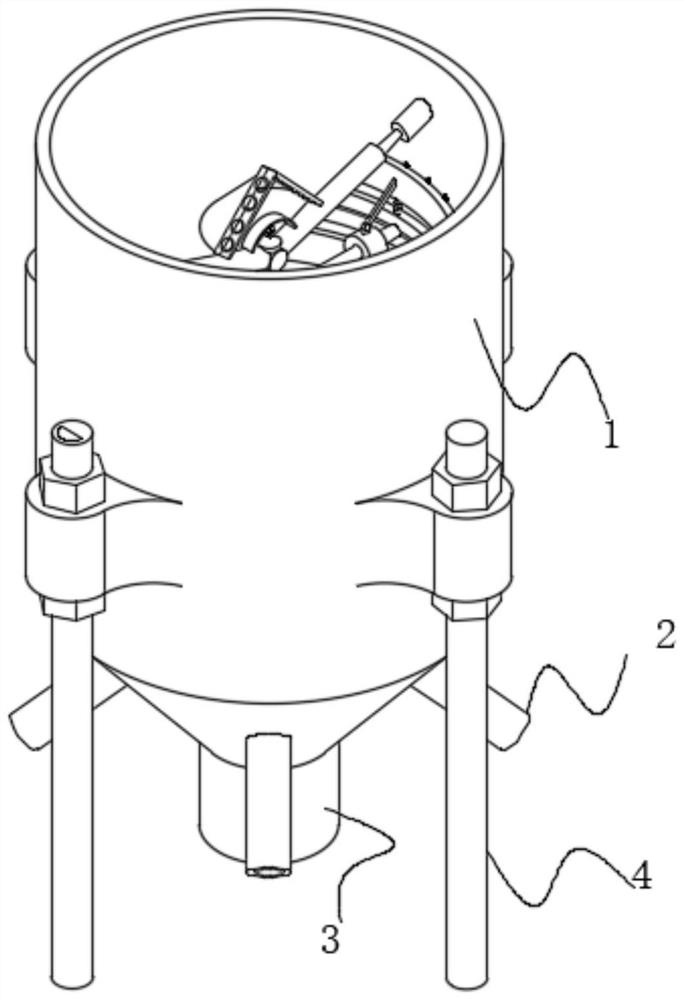

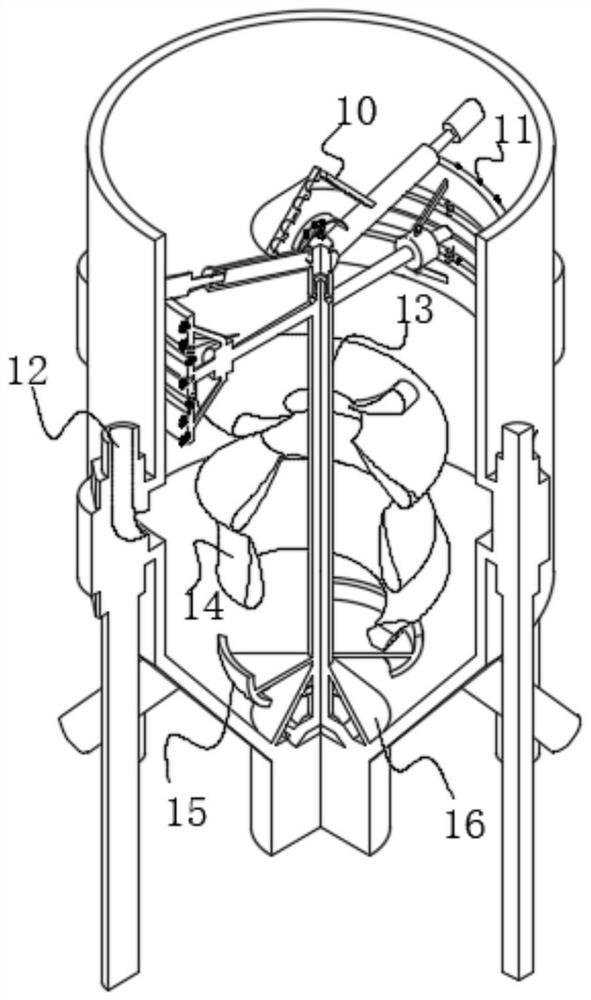

Removal device for organic matters of wastewater

InactiveCN105152307AAdjust the number of cyclesAdjust reaction timeTreatment using aerobic processesWater/sewage treatment by irradiationWastewaterEngineering

The invention relates to a removal device for organic matters of wastewater. The removal device is characterized by comprising an upright cylindrical tubular body, wherein an internal flow guide cylinder, of which the lower part is provided with a flow guide cover, is arranged in the center of the tubular body, a water inlet pipe is arranged in the flow guide cover, the lower part of the flow guide cover is provided with an aerator, a filler layer is arranged inside the flow guide cover, a plurality of ultraviolet lamp tubes are further uniformly distributed inside the flow guide cover, and a water outlet is located at the upper part of the tubular body.

Owner:CEEP CO LTD

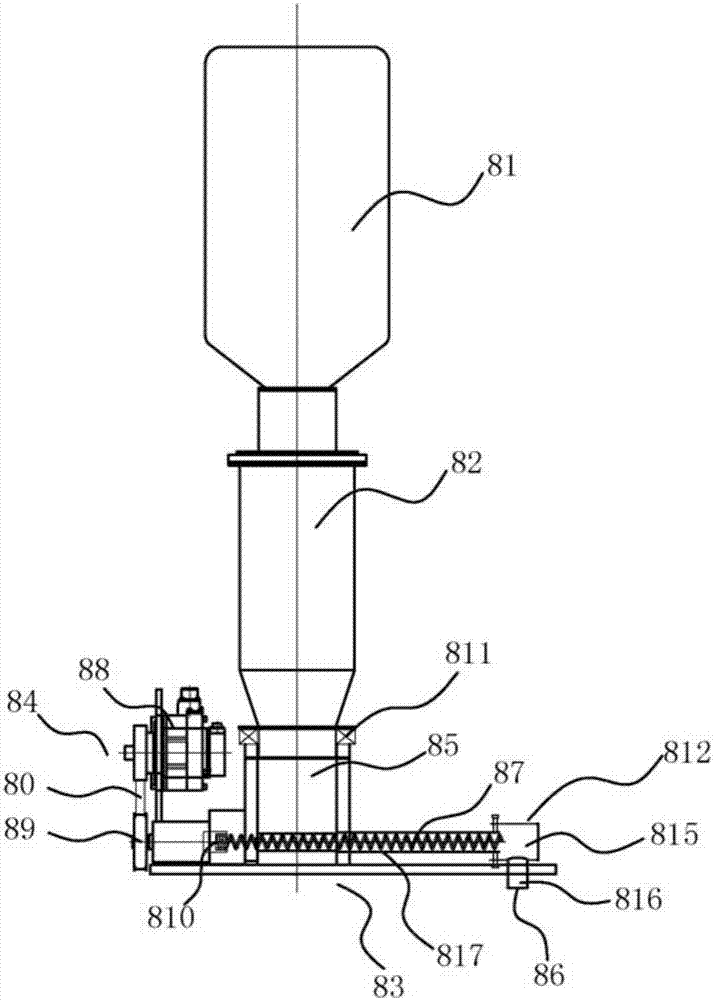

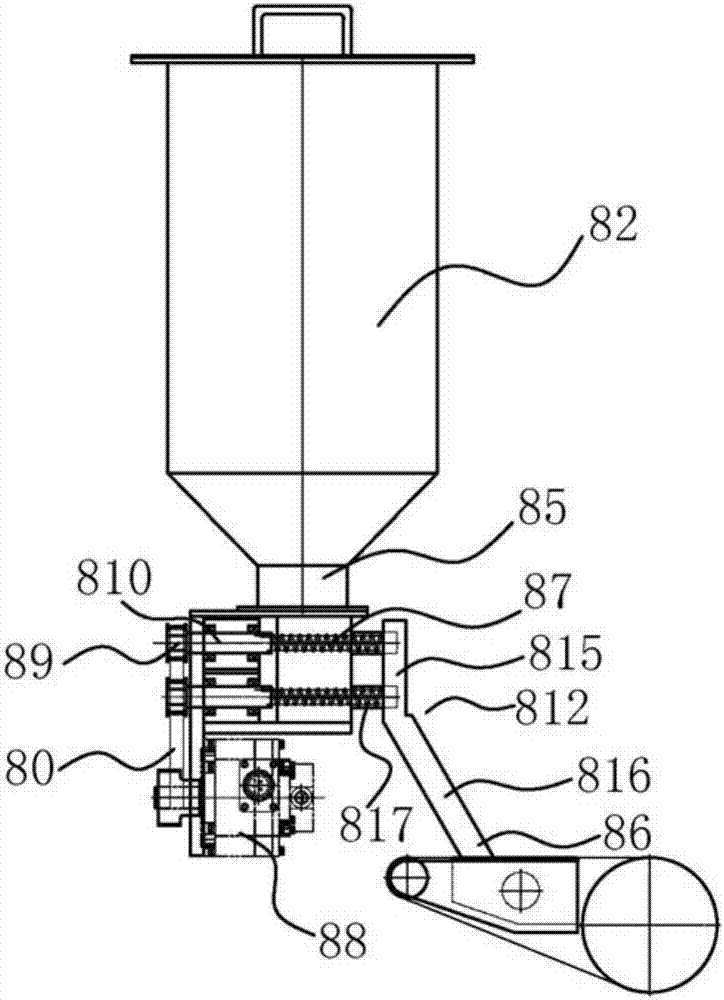

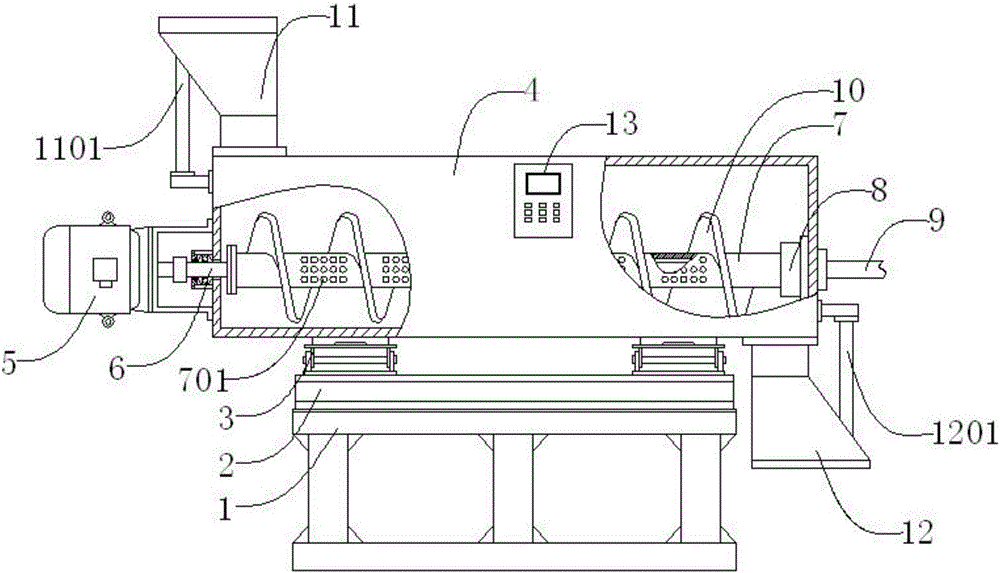

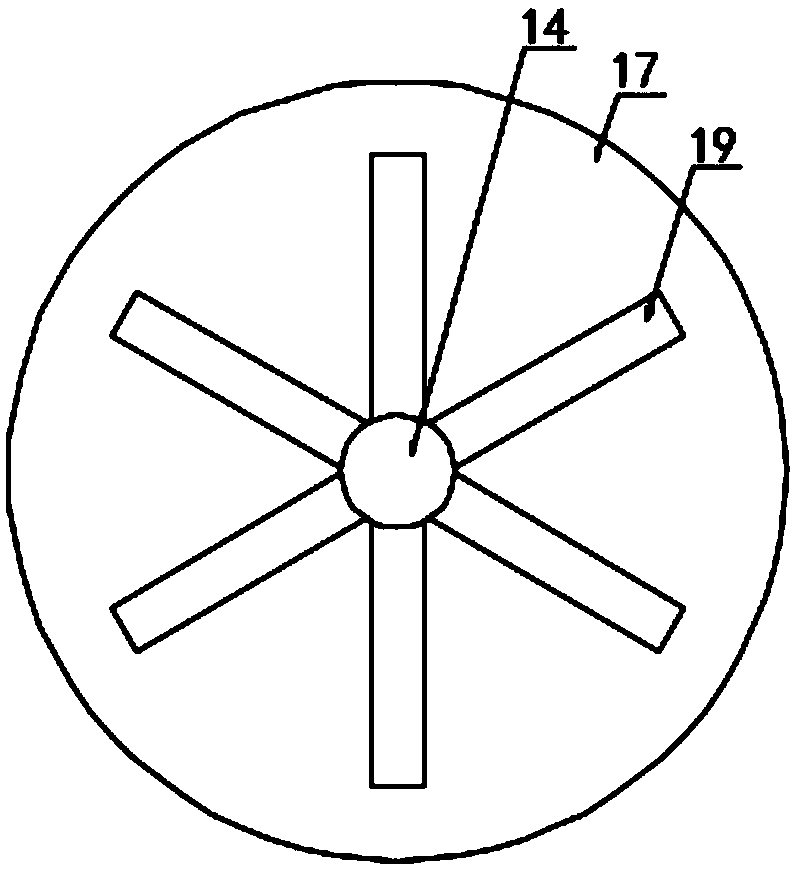

Pre-mixing type spiral powder feeding device

InactiveCN106672561APrecise output controlSimple structureMixer accessoriesPackagingBiochemical engineeringBlend time

The invention discloses a pre-mixing type spiral powder feeding device which comprises a rack, a plane table, weighing sensors, a box, a motor, a rotating shaft, a hollow shaft, a sealing seat, a blowing pipe, a spiral impeller, a feeding nozzle, a discharging nozzle and a controller. Raw materials and a modifier are fed into the box through the feeding nozzle, and the controller controls the motor to drive the spiral impeller fixedly connected with the hollow shaft to rotate through the rotating shaft, so that the raw materials and the modifier are continuously conveyed; meanwhile, compressed air is pumped into the hollow shaft through the blowing pipe, so that the raw materials and the modifier are blown up, and the raw materials and powder are mixed; and the raw materials and the modifier are mixed and pushed to move forwards by the spiral impeller at the same time till mixtures are discharged from the discharging nozzle, and the weighing sensors are used for weighing, so that the output amount of the raw materials and the modifier is precisely controlled. The pre-mixing type spiral powder feeding device is simple in structure, the raw materials and the modifier are mixed and pushed to move forwards by the spiral impeller at the same time so as to be mixed in advance, the subsequent modification mixing time is shortened, and modification efficiency is improved.

Owner:安徽金鼎新材料有限公司

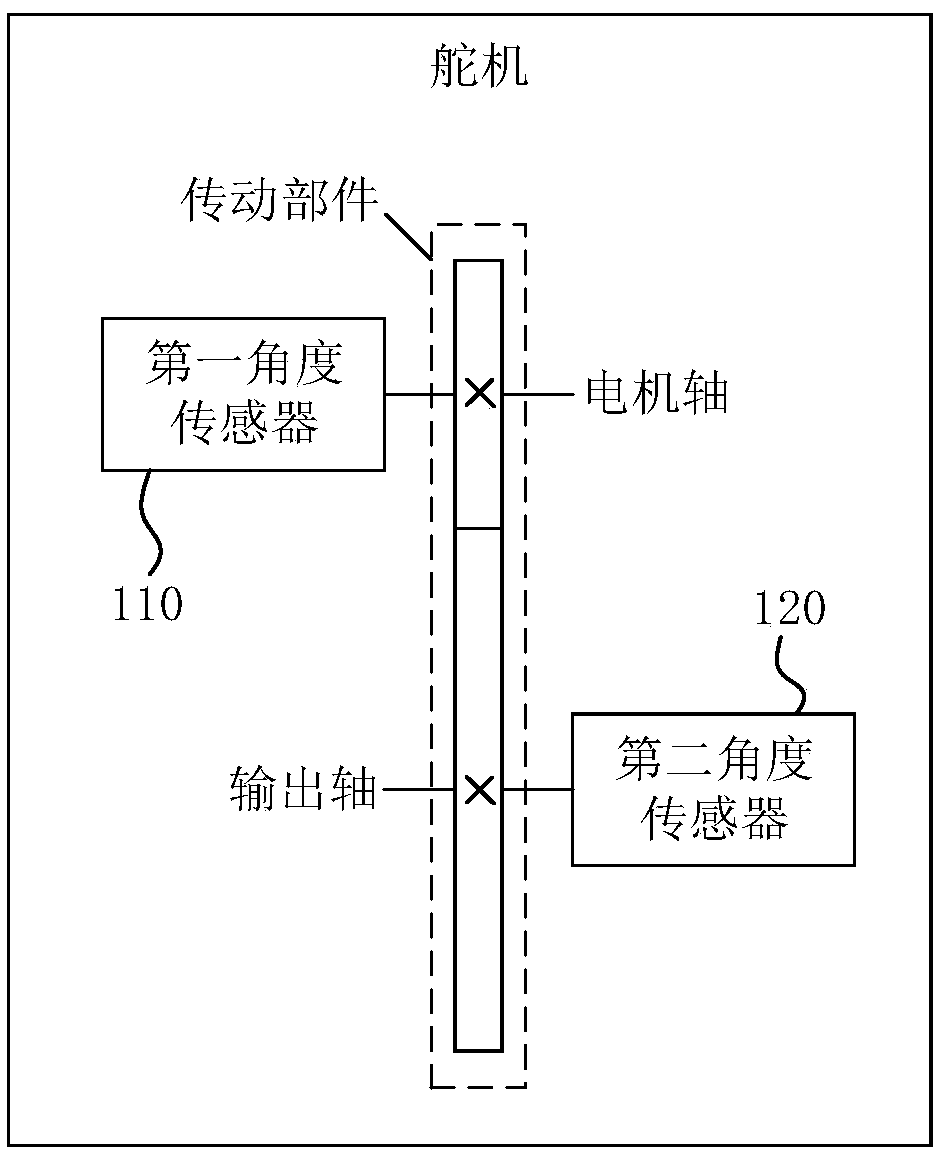

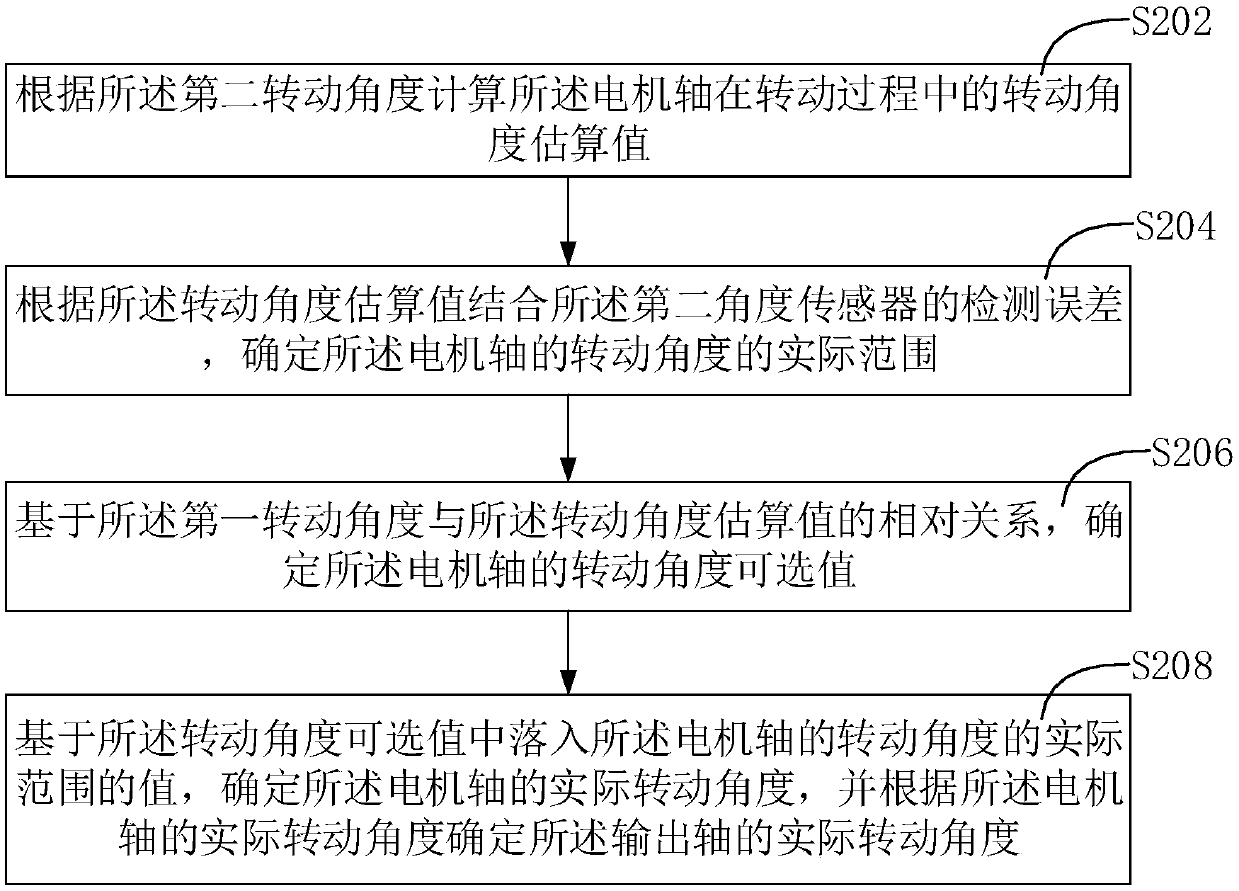

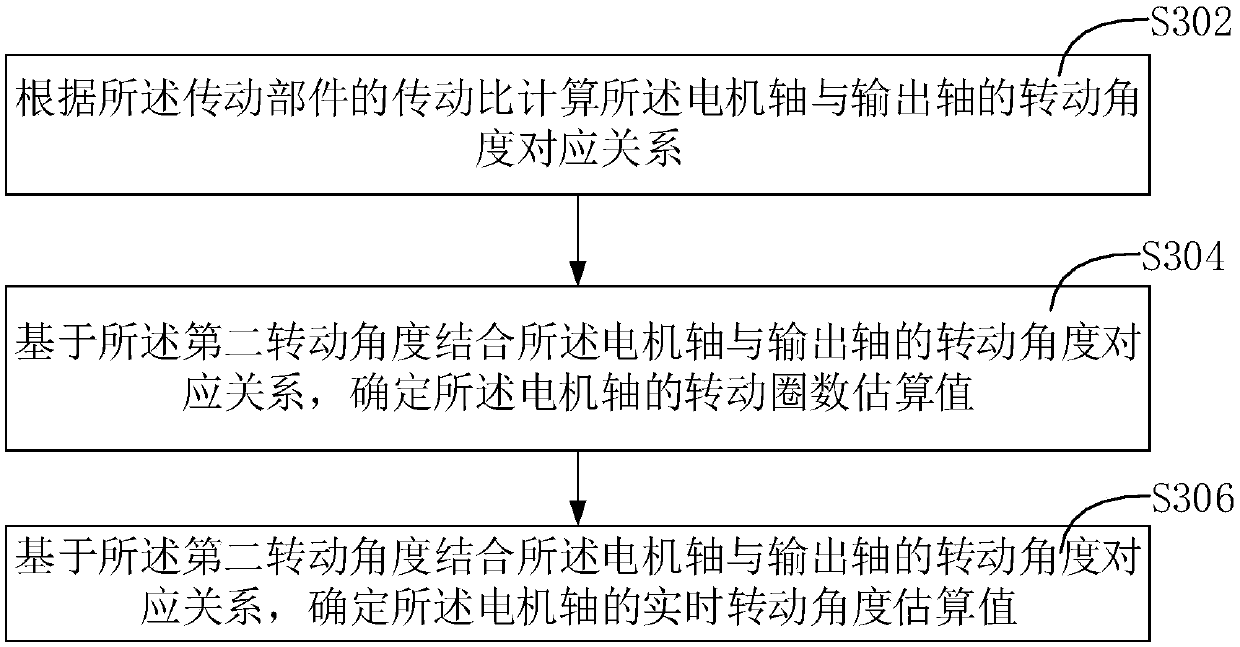

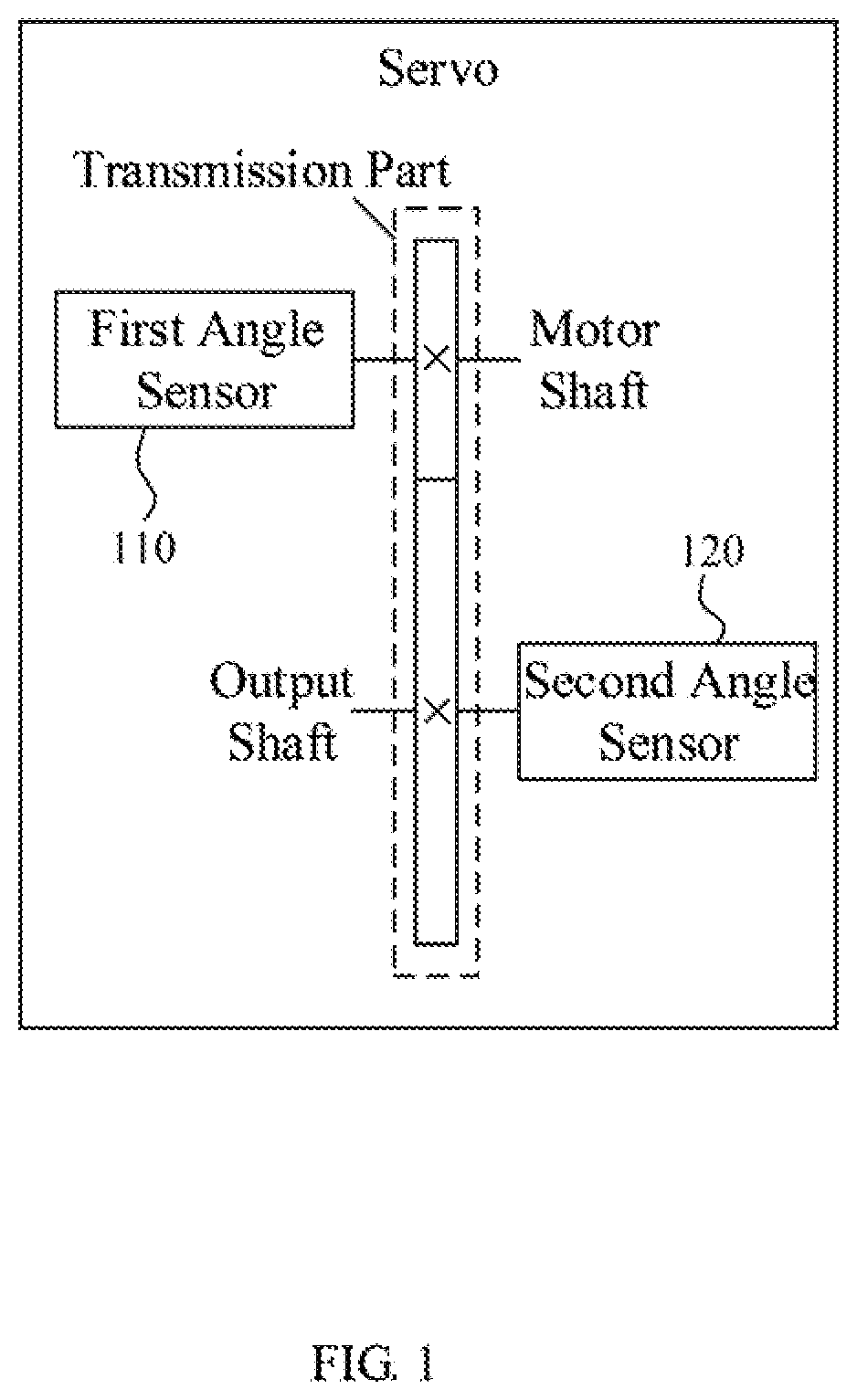

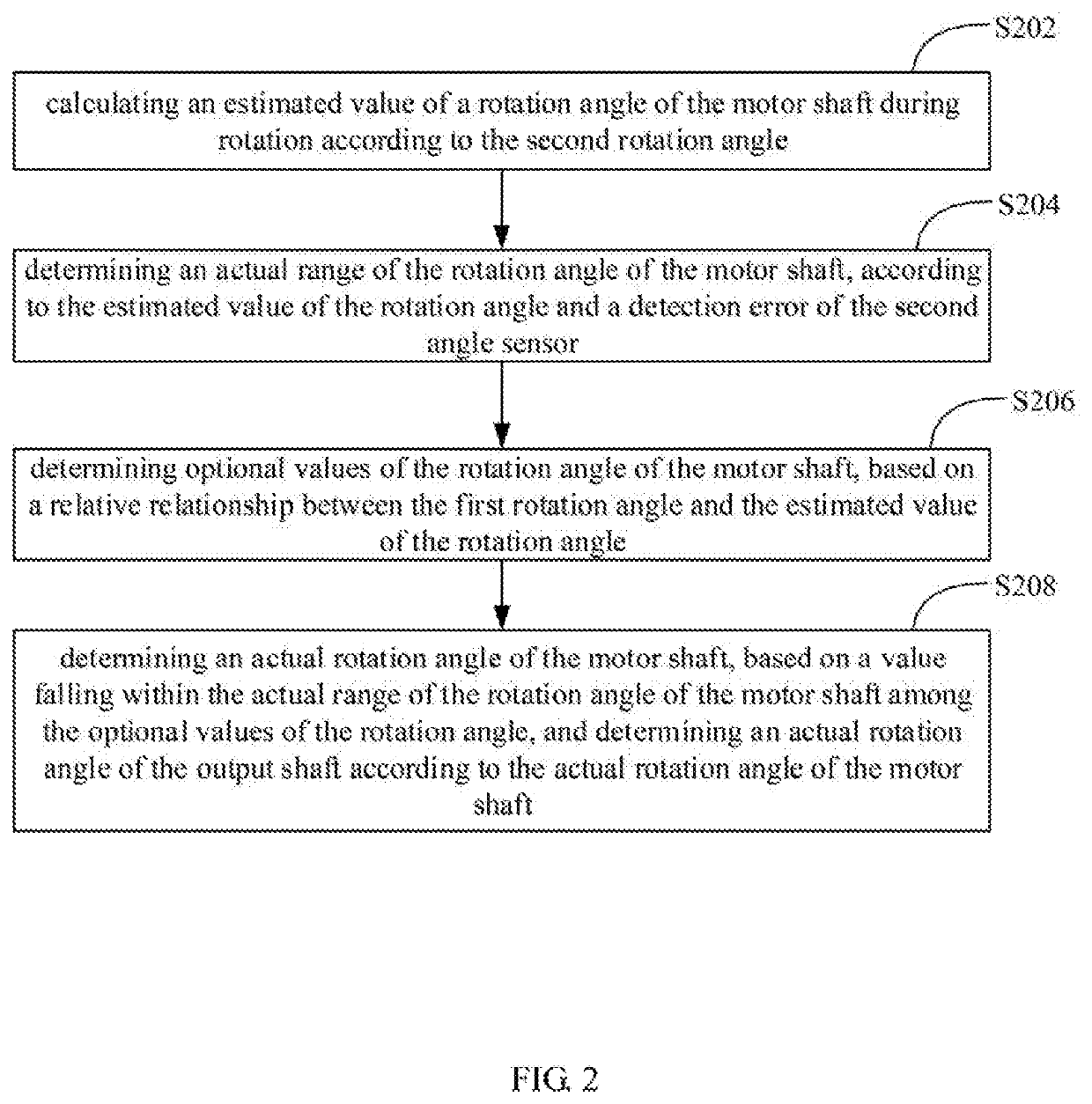

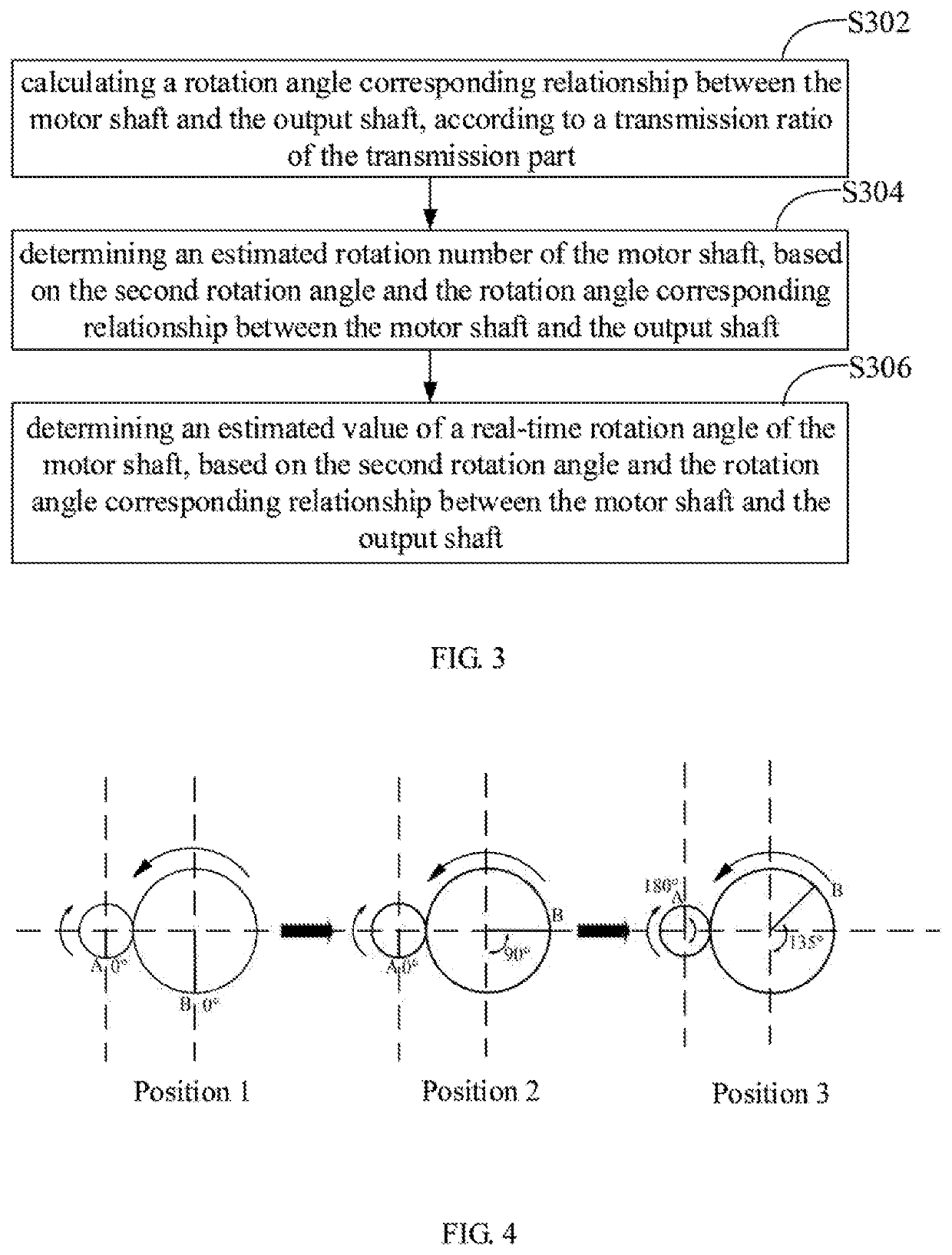

Rotation angle detection method and device

ActiveCN111380499AHigh measurement accuracyPrecise output controlMeasurement devicesElectric machineryEngineering

The embodiment of the invention discloses a method and device for detecting a rotation angle of a steering engine. The method comprises the following steps: calculating a rotation angle estimated value of a motor shaft in a rotation process according to a second rotation angle; determining the actual range of the rotation angle of the motor shaft according to the estimated value of the rotation angle in combination with the detection error of the second angle sensor; determining a rotation angle selectable value of the motor shaft based on the relative relationship between the first rotation angle and the rotation angle estimated value; determining the actual rotation angle of the motor shaft based on the value falling into the actual range of the rotation angle of the motor shaft in the rotation angle selectable value, and determining the actual rotation angle of the output shaft according to the actual rotation angle of the motor shaft. Through the method, the measurement precision of the rotation angle of the output shaft of the rotating mechanism can be improved, the influence on the overall error of the system caused by the precision error of the angle sensor is greatly reduced, and the output control of the rotating mechanism is more accurate.

Owner:UBTECH ROBOTICS CORP LTD

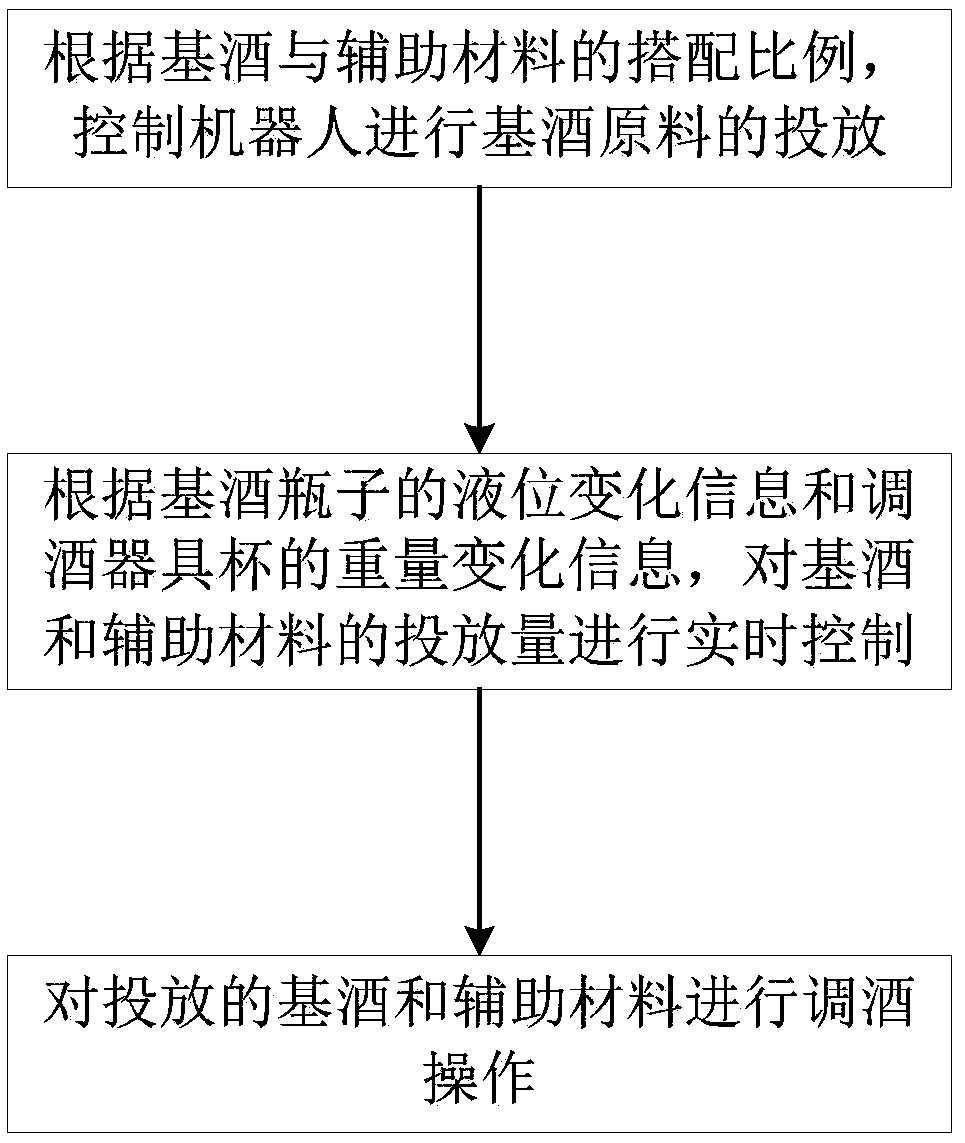

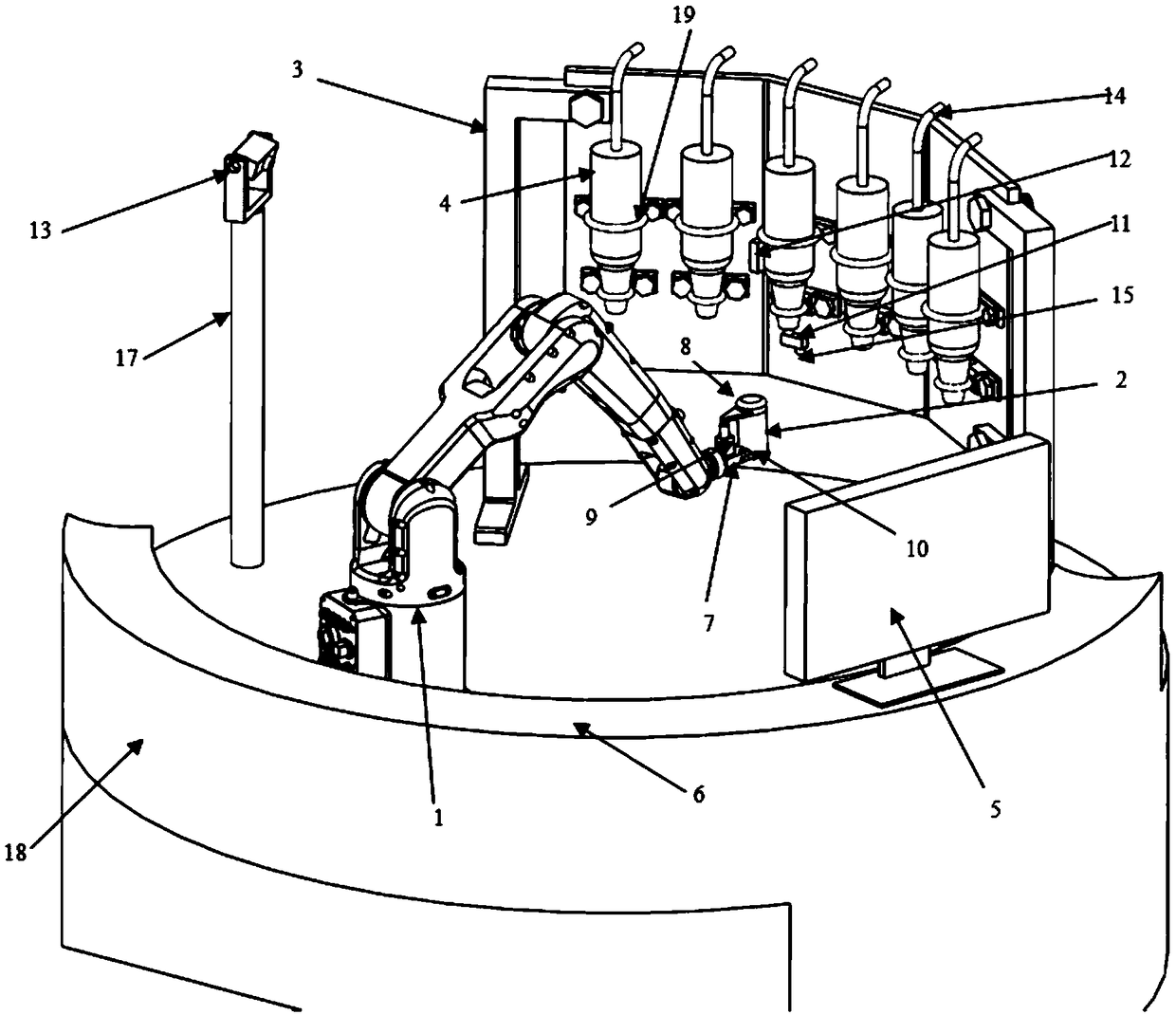

Bartending robot automatic control system and realization method thereof

InactiveCN108983654APrecise output controlEnsure consistencyProgramme controlComputer controlComputer control systemAutomatic control

The invention discloses a bartending robot automatic control system and a realization method thereof. The system comprises an upper computer control system, a robot control system, a liquid level sensor and a weight sensor. The method comprises the following steps of according to the matching proportion of base wine and an auxiliary material, making a robot release a base wine material; carrying out real-time control on the release amount of the base wine and the auxiliary material according to the liquid level change information of a base wine bottle and the weight change information of a bartending device cup; and carrying out bartending operation on the released base wine and the auxiliary material. In the invention, automation control during a bartending process is realized and manualbartending cost is reduced; the discharging amount of the base wine material can be accurately controlled, the consistency of bartending products is ensured, the leakage of raw materials is preventedand cost is further reduced; and the system and the method can be widely applied to the automation equipment technology field.

Owner:深圳市智能机器人研究院

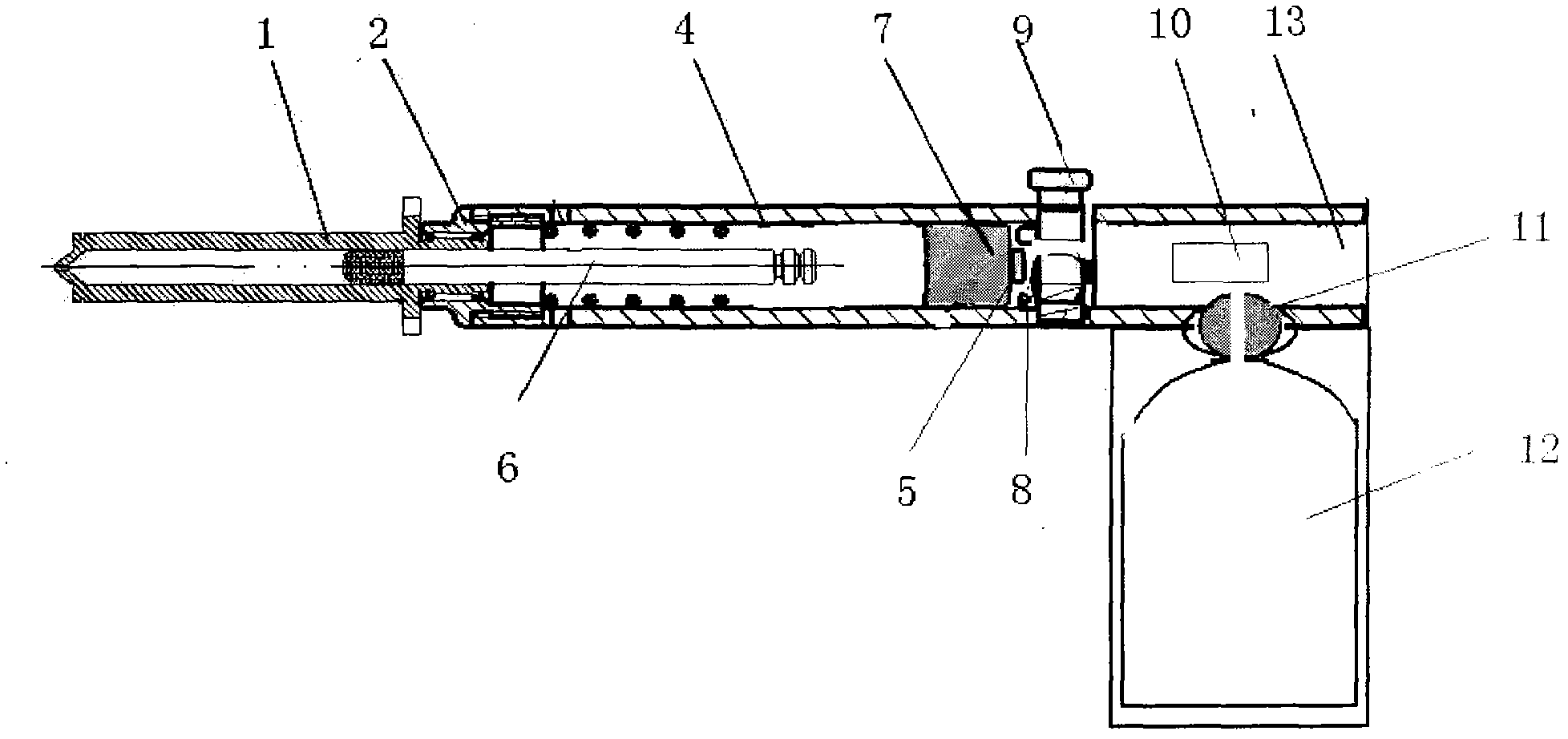

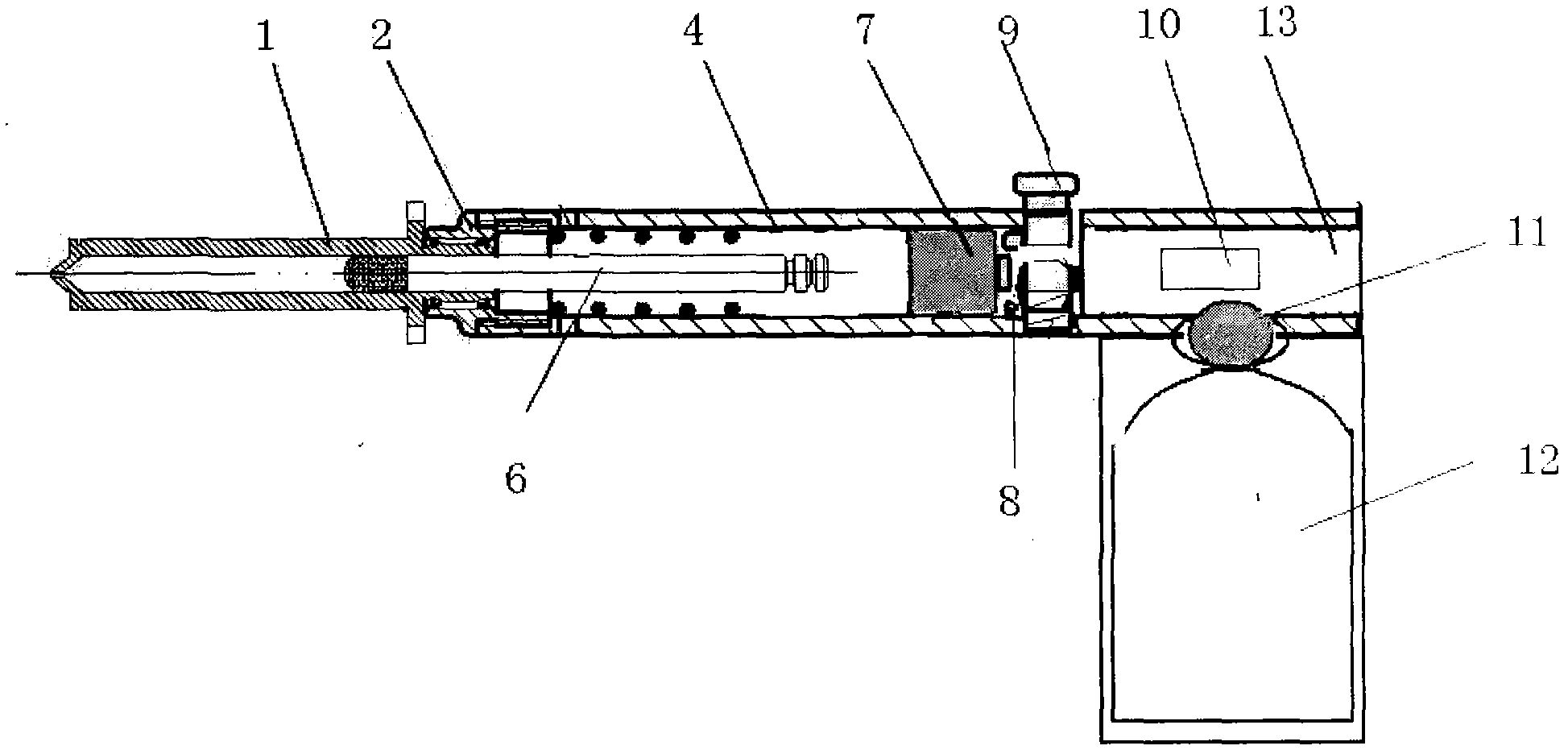

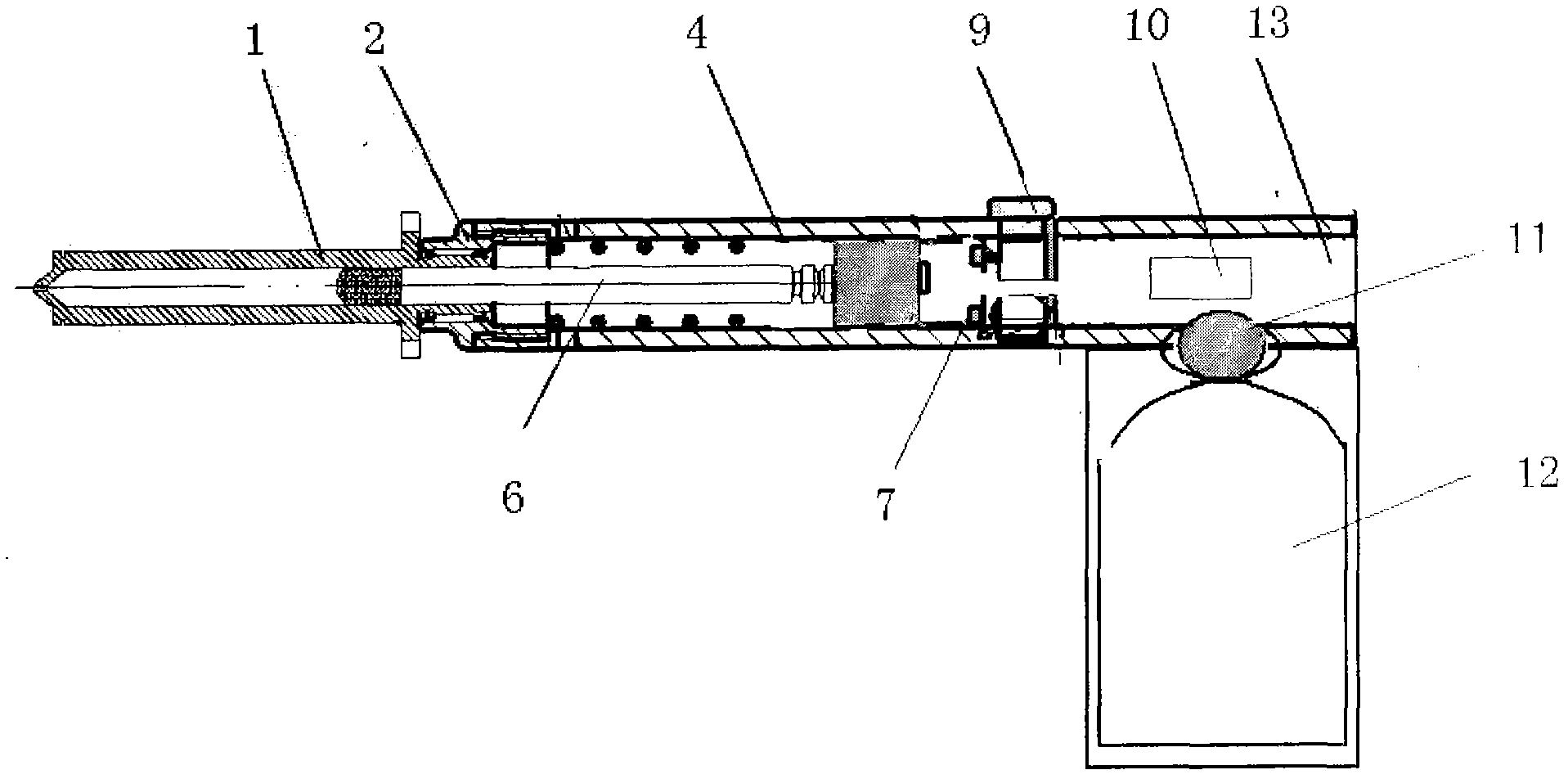

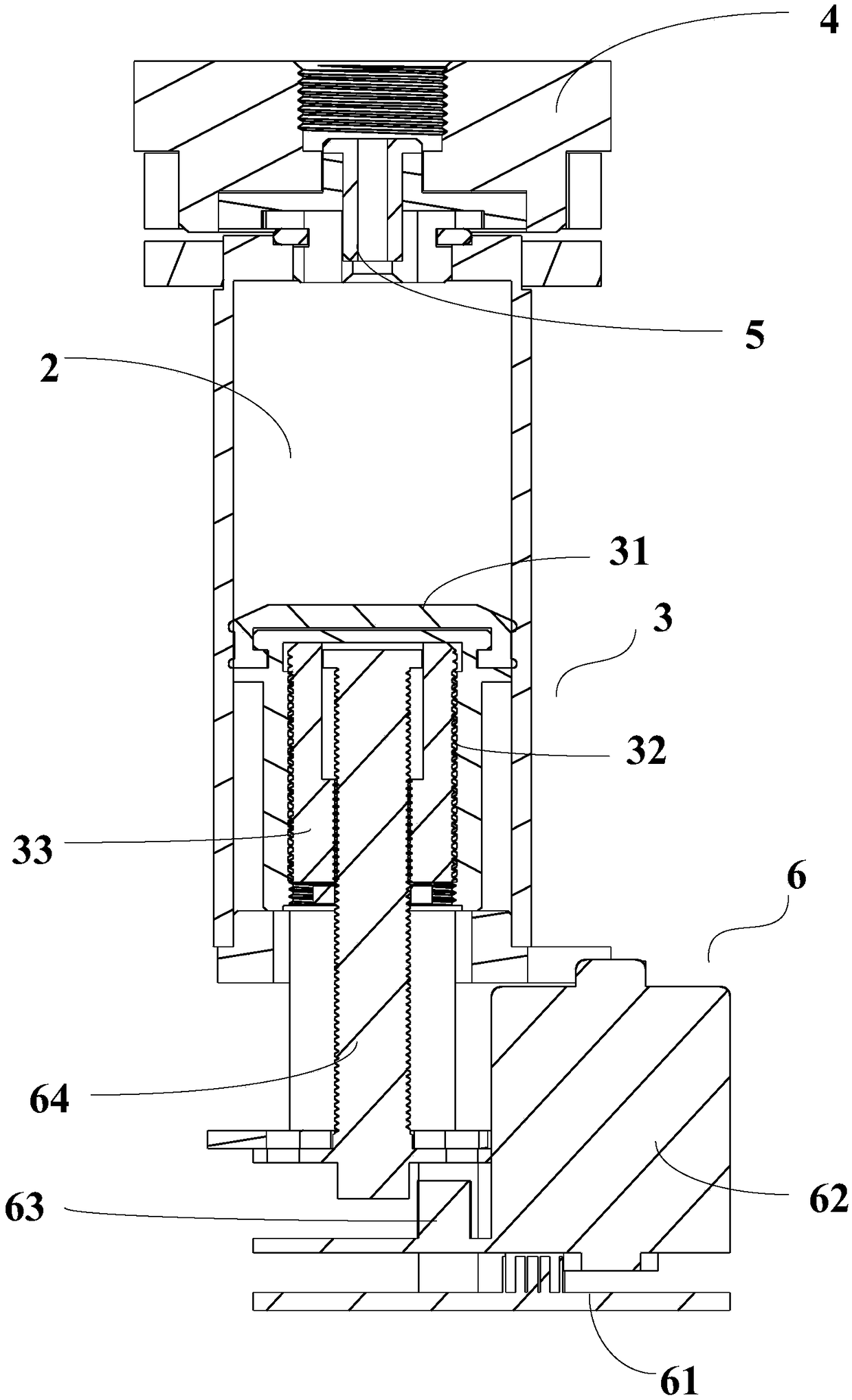

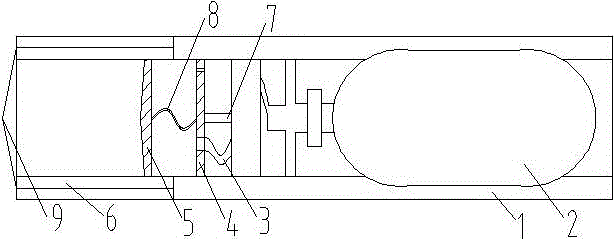

Needleless injection syringe

InactiveCN106474599APrecise output controlWon't enterJet injection syringesIntravenous devicesNeedle Free InjectionGas cylinder

The invention discloses a needleless injection syringe. The needleless injection syringe comprises a cylinder-shaped shell, an injection head and a pneumatic device, wherein the pneumatic device is arranged at the upper part in the shell, a medicine storage tube is arranged at the lower part in the shell, a piston is mounted in the medicine storage tube, the piston is match mounting with the pneumatic device, the exposed end of the medicine storage tube is provided with the injection head, the pneumatic device comprises an air storage bottle, air guide pipes and a mobile plug, the air storage bottle is fixedly mounted in the shell, the outlet of the air storage bottle is connected with a switch device, the outlet of the switch device is connected with one or more air guide pipes, the outlet end (s) of the air guide pipe(s) is / are fixedly mounted on an air hole formed in the mobile plug, and the air hole is a through hole axially communicated along the axis of the mobile plug. The invention aims at providing the needleless injection syringe capable of being used for a plurality of times after being charged with liquid once.

Owner:成都测迪森生物科技有限公司

Stirring equipment for cement production

PendingCN113829502AAvoid cloggingAvoid damageCement mixing apparatusSold ingredients supply apparatusEngineeringCentrifugal force

The invention belongs to the field of cement production, and particularly relates to stirring equipment for cement production. The stirring equipment for cement production comprises a machine body, wherein a discharging pipe is fixedly installed on the outer surface of the machine body; a motor is arranged at the bottom of the discharging pipe; the upper surface of the motor is fixedly connected with the lower surface of the machine body; and a supporting rod is in threaded connection with the outer surface of the machine body. According to the stirring equipment for cement production, by arranging a cleaning mechanism, when a connecting shaft rotates, a sliding block moves rightwards along the outer surface of a guide rod under the effect of centrifugal force, the dip angle of an adjusting rod is increased, an elastic soft rod extends, a sliding block extrudes a pressing plate, an arc-shaped plate moves rightwards along the outer surface of a horizontal rod while being unfolded, and a reset spring extends; and by increasing the pressure, the surface area and the friction force, the cleaning efficiency is improved, the cleaning mechanism can assist in stirring while completing internal cleaning, and the problems that after traditional cement production equipment completes work, the interior can be easily oxidized and hardened, cleaning is not easy, and normal work of the equipment is affected are solved.

Owner:鲜孝刚

Small-sized mixer

InactiveCN104645855ANo pollution in the processWell mixedRotary stirring mixersMixer accessoriesEngineeringTimer

The invention discloses a small-sized mixer. The small-sized mixer comprises a housing, wherein an outer cover is arranged on the upper part of the housing; an electric valve plate and a discharge hole of a discharge counter are arranged at one side of the bottom of the housing; a motor is arranged on the bottom of the housing, and is connected with a stirring device; the stirring device comprises a stirring shaft, a first stirring paddle and a plurality of second stirring paddles; the second stirring paddles are arranged on the stirring shaft; the first stirring paddle is fixed on one second stirring paddle; a controller is arranged at one end of the bracket; a switch, a rotation speed regulator, a timer and an alarm are arranged on the controller. According to the small-sized mixer disclosed by the invention, the first stirring paddle and the second stirring paddles rotate to solve an uneven material mixing problem; the timing controller controls the stirring time, the stirring motor automatically stops and the alarm emits a warning when preset stirring time is reached. The small-sized mixer can be used for precisely controlling the material discharge, is adjustable in rotation speed, can be dismounted, is easy to clear and convenient to move; during working, the small-sized mixer is of a completely sealed structure, so that the whole mixing process is free of dust pollution.

Owner:ANHUI SONGTAI PACKAGING MATERIALS

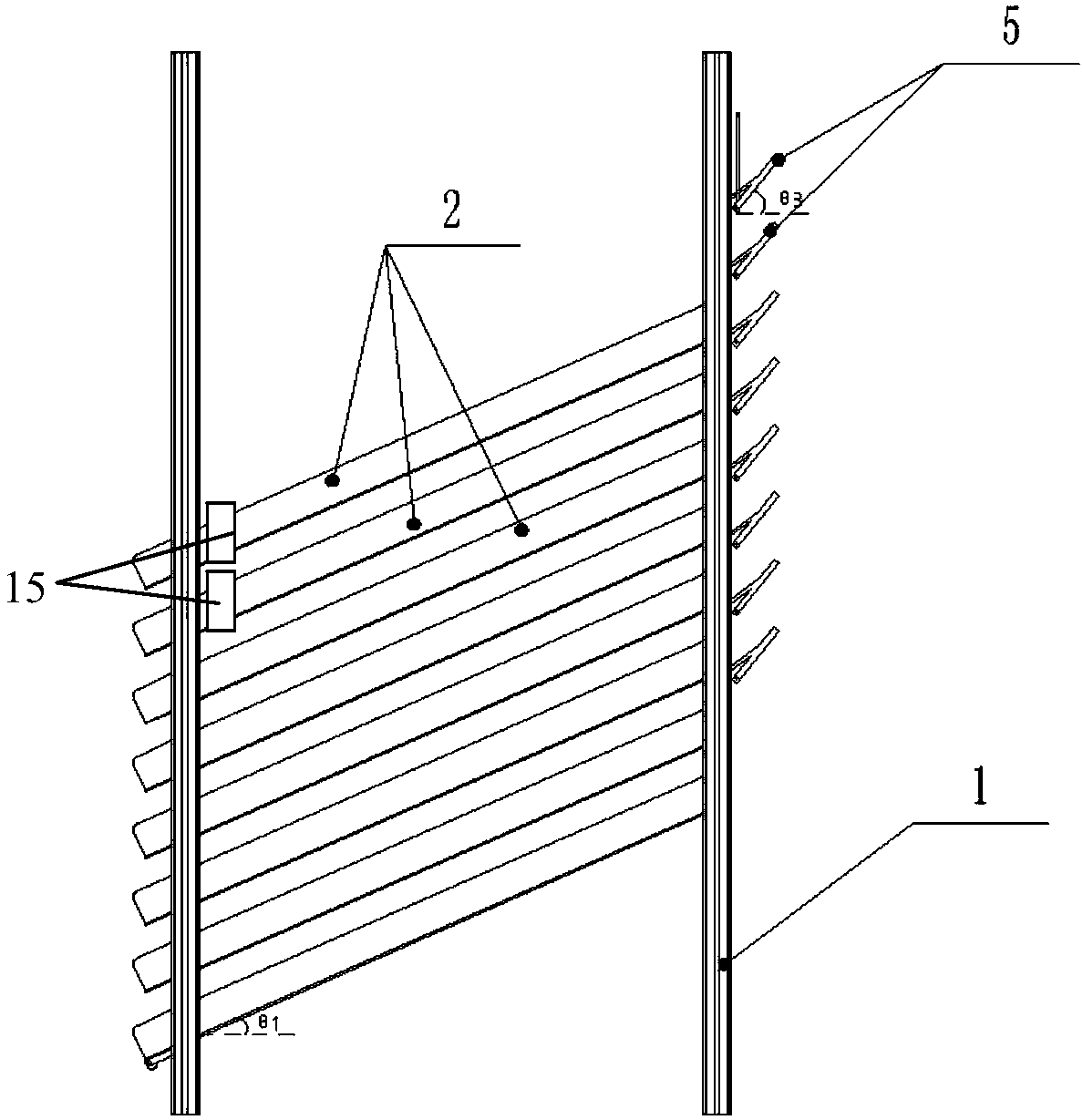

Discharge structure

ActiveCN108113887ASlow and steady slideImprove general performanceOral administration deviceCamElectrical and Electronics engineering

The invention relates to a discharge structure comprising a bracket; at least one slideway, a blocking part and at least one cam and / or at least one eccentric wheel, wherein the at least one slidewayis slantly mounted on the bracket and used for supporting a to-be-conveyed article and enabling the to-be-conveyed article to slide down by means of its own gravity; the blocking part is disposed at the bottom end of the slideway and used for preventing the to-be-conveyed article from further sliding down; and the at least one cam and / or the at least one eccentric wheel are / is disposed at the bottom end of the slideway and used for jacking up the to-be-conveyed article by rotation, so that the to-be-conveyed article crosses across the blocking part to continue to slide down. The discharge structure can ensure medicine boxes are output one by one quickly and accurately.

Owner:SOLEE WUHAN SCI & TECH

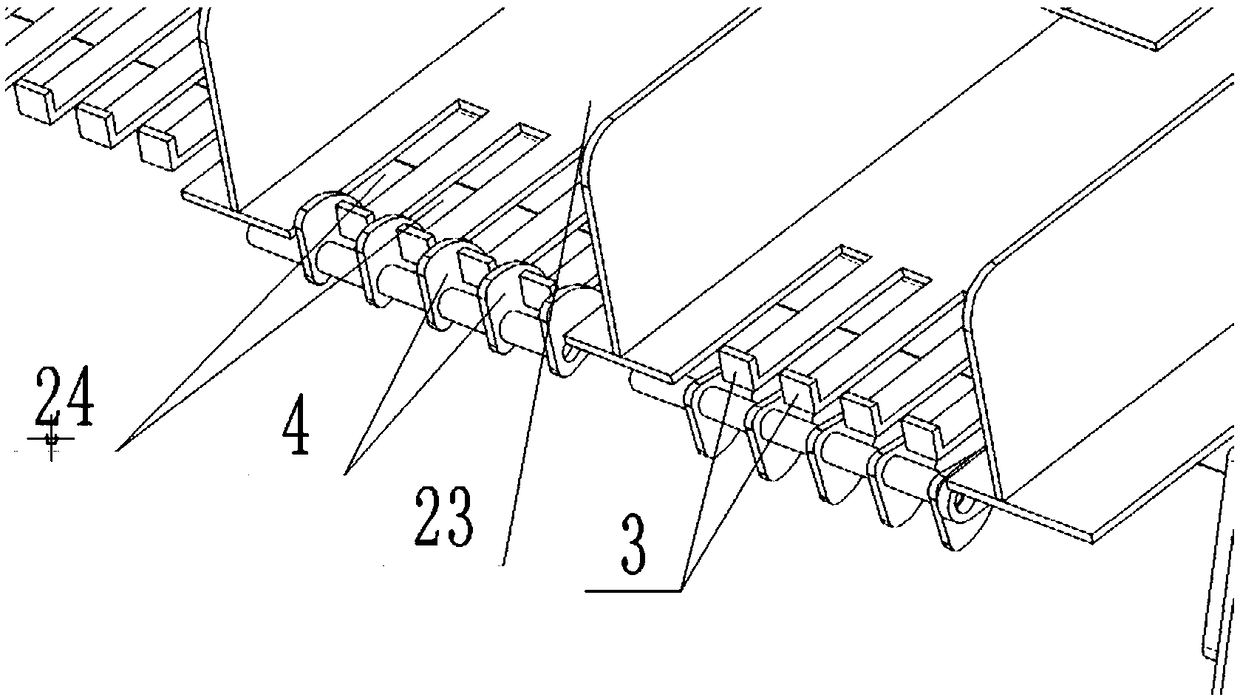

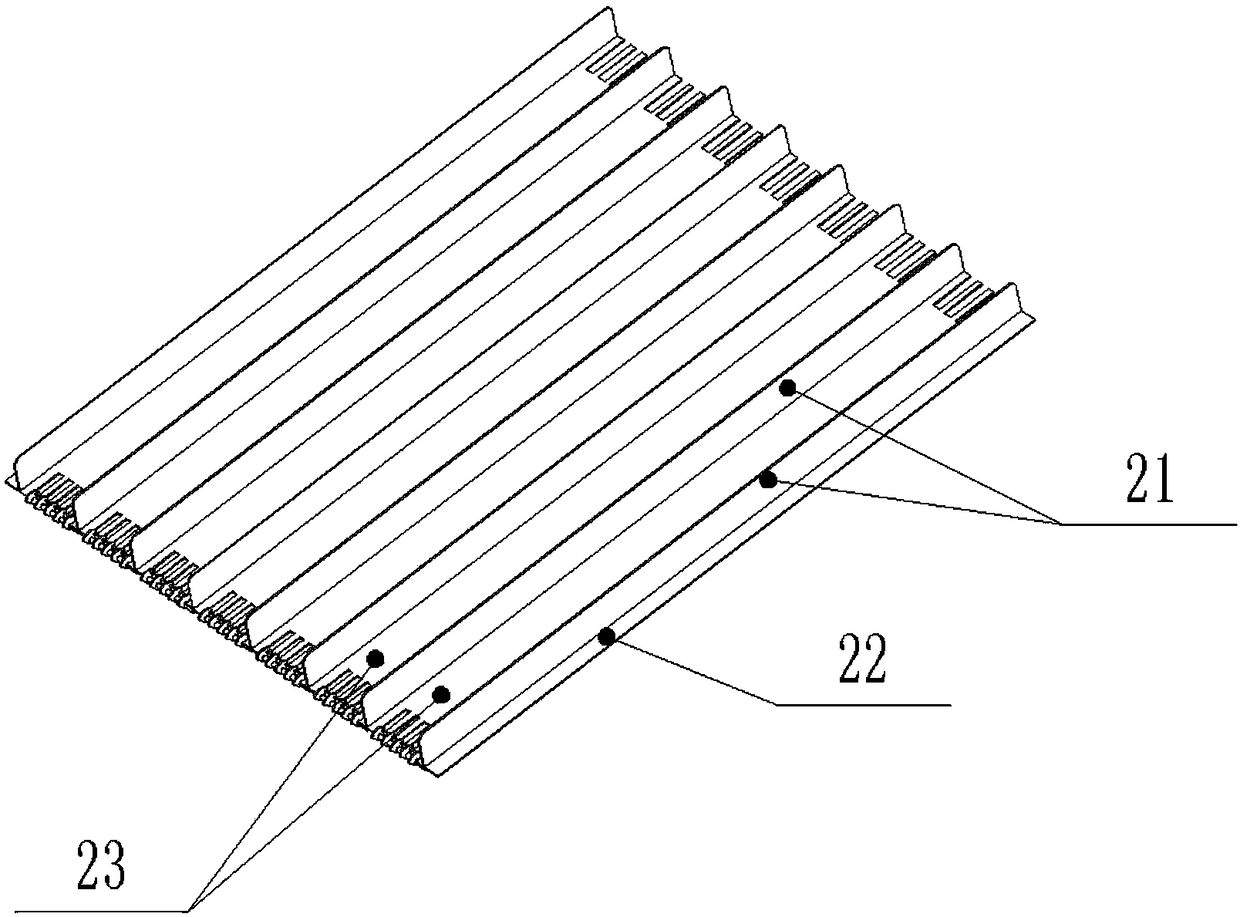

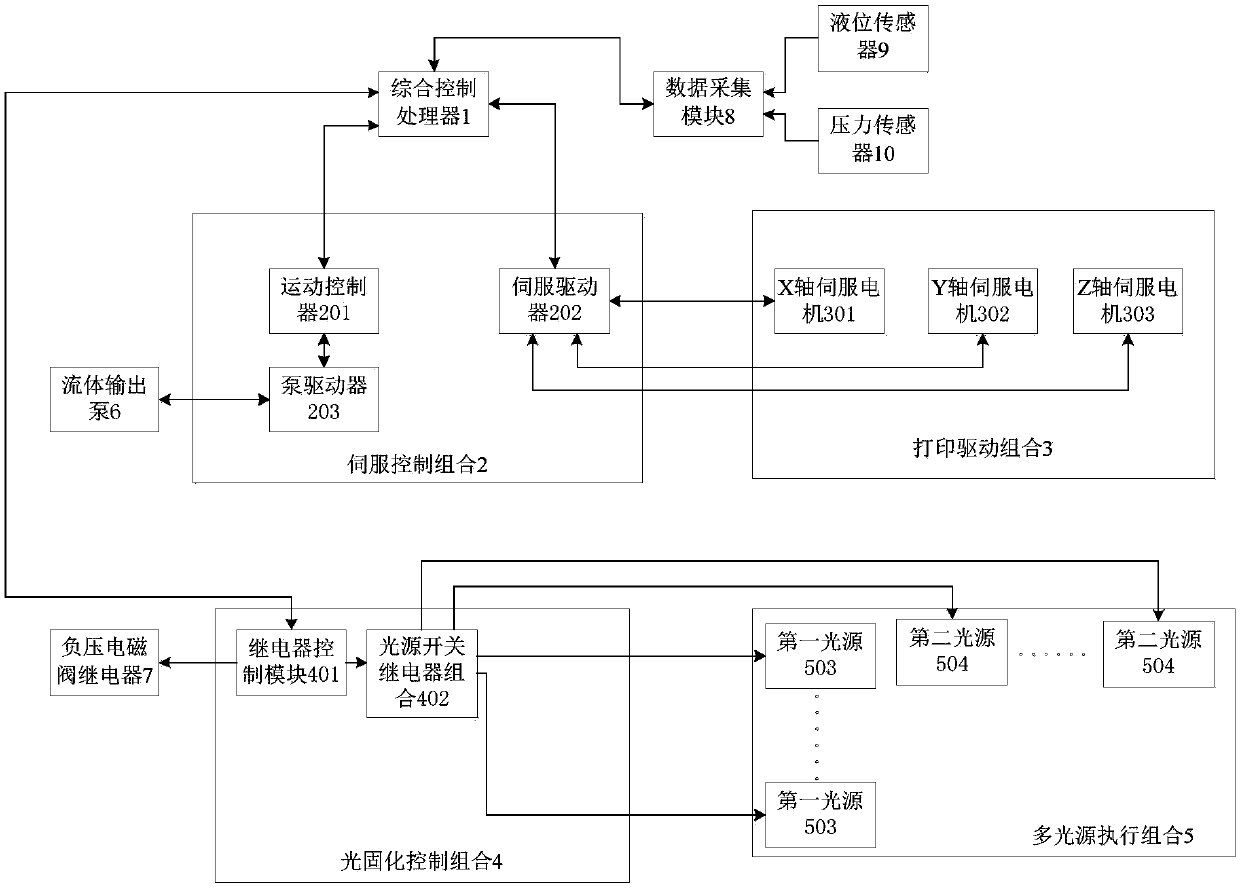

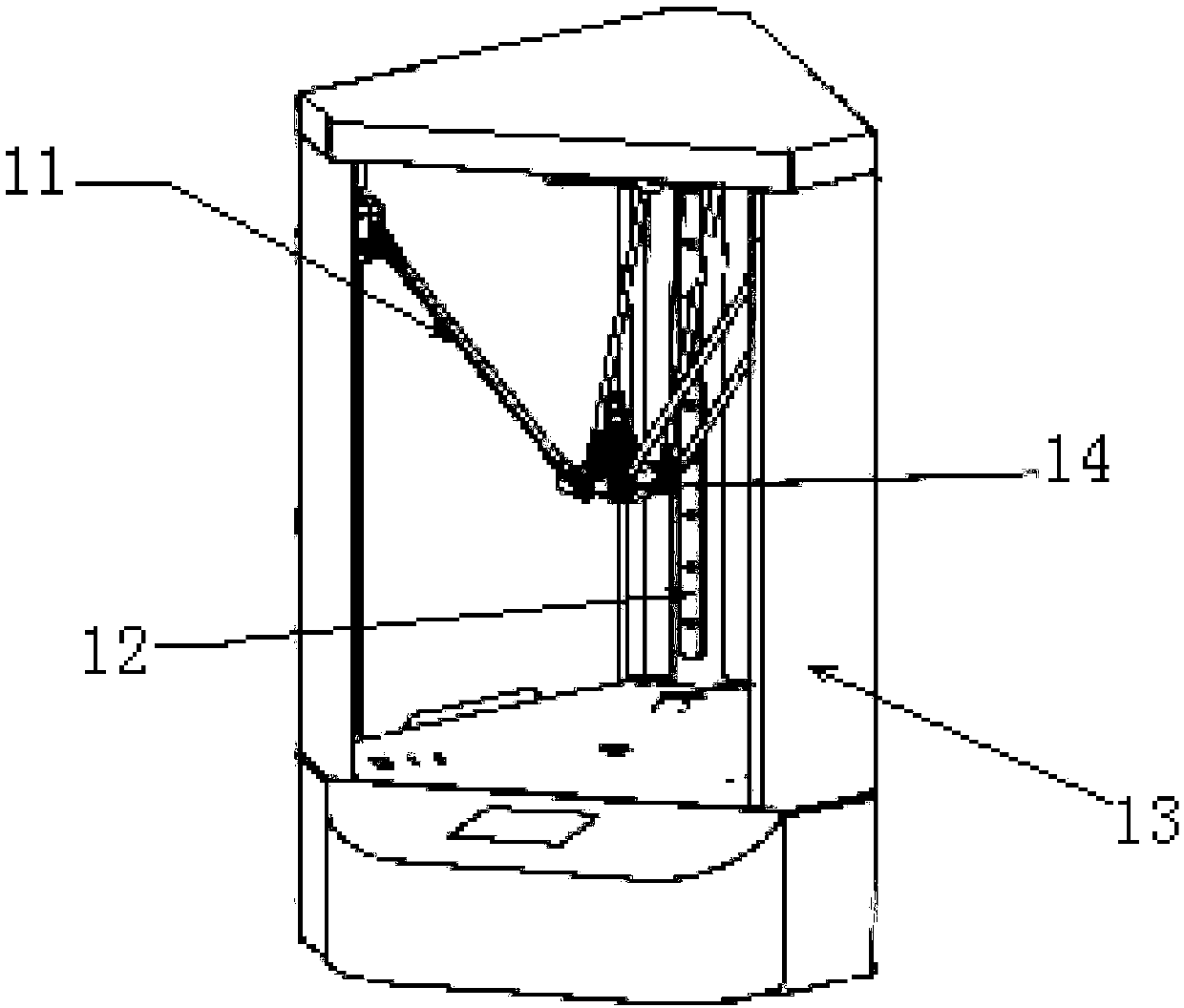

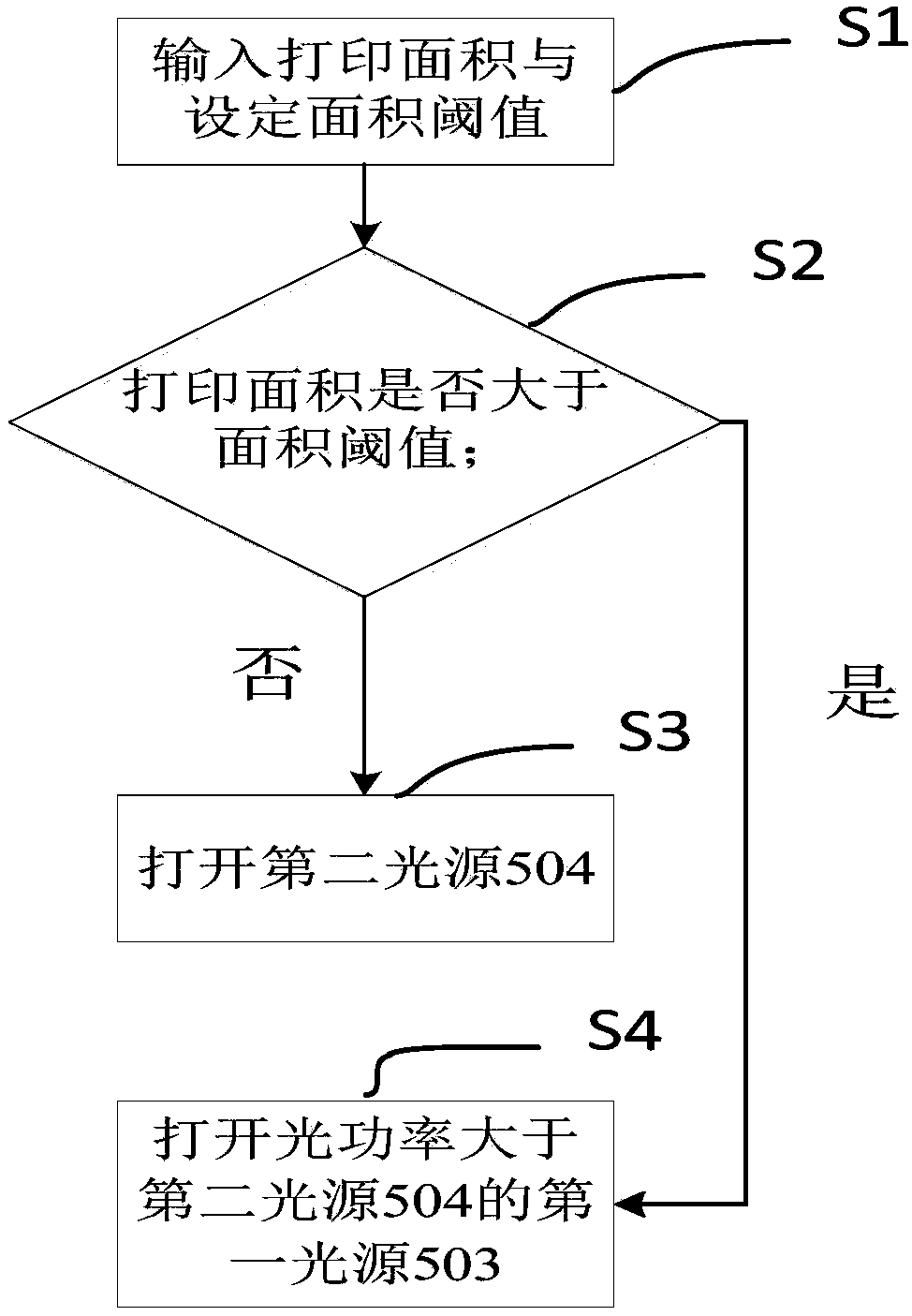

Control system and control method for novel visible light curing 3D printer

ActiveCN109940879AReduce biasImprove curing effectAdditive manufacturing apparatus3D object support structuresControl systemEngineering

The invention relates to the technical field of 3D printing control, and discloses a control system for a novel visible light curing 3D printer. The control system comprises a comprehensive control processor, a servo control combination, a printing driving combination, a light curing control combination and a multi-light source executing combination. The comprehensive control processor is in communication connection to the servo control combination and the light curing control combination, separately, for controlling the servo control combination and the light curing control combination in a linked manner. The invention also discloses a control method for the novel visible light curing 3D printer. The control method comprises the following steps: S1, inputting a printing area and a settingan area threshold value; S2, judging whether the printing area is larger than the area threshold value or not; if not, executing the S3 and if so, executing the S4; S3, turning on a second light source; and S4, turning off a first light source, the light power of which is greater than that of the second light source. According to the invention, the using cost of the light sources is lowered, theprinting precision and speed are improved, and the working reliability and stability of the light curing 3D printer are improved, too.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

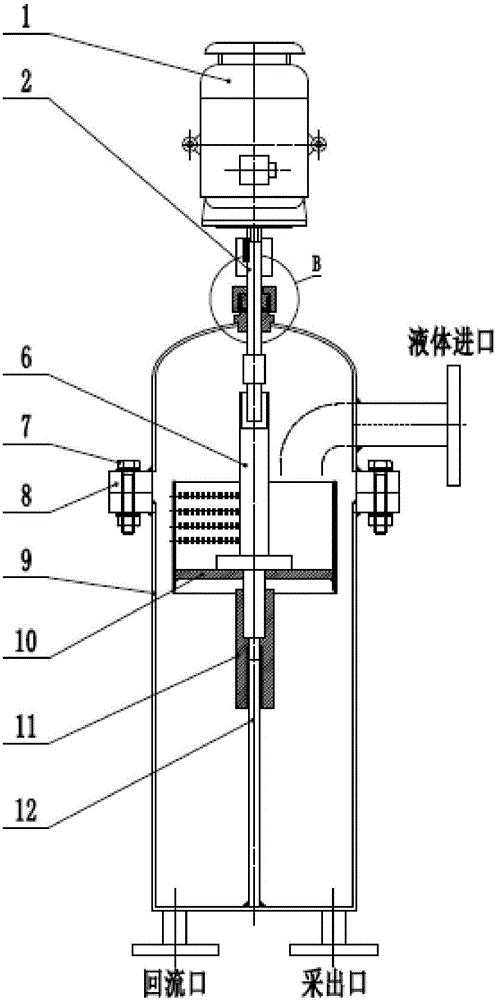

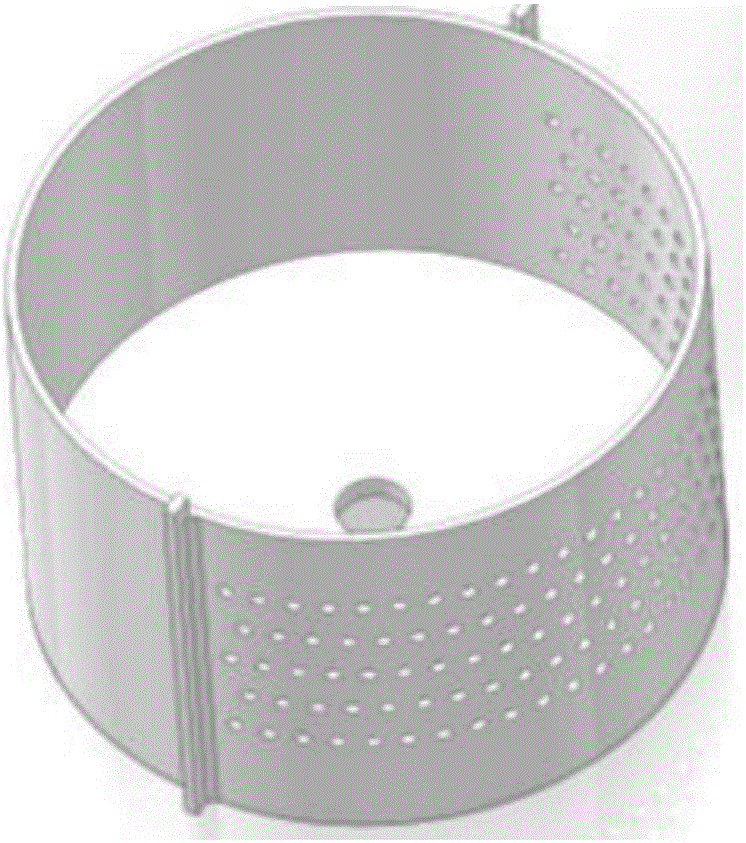

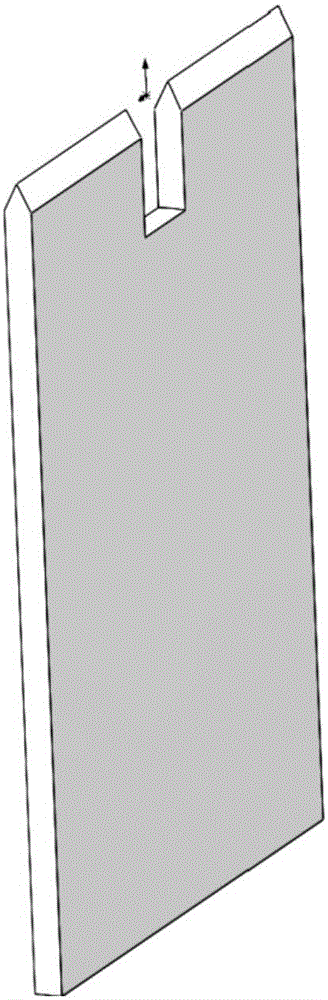

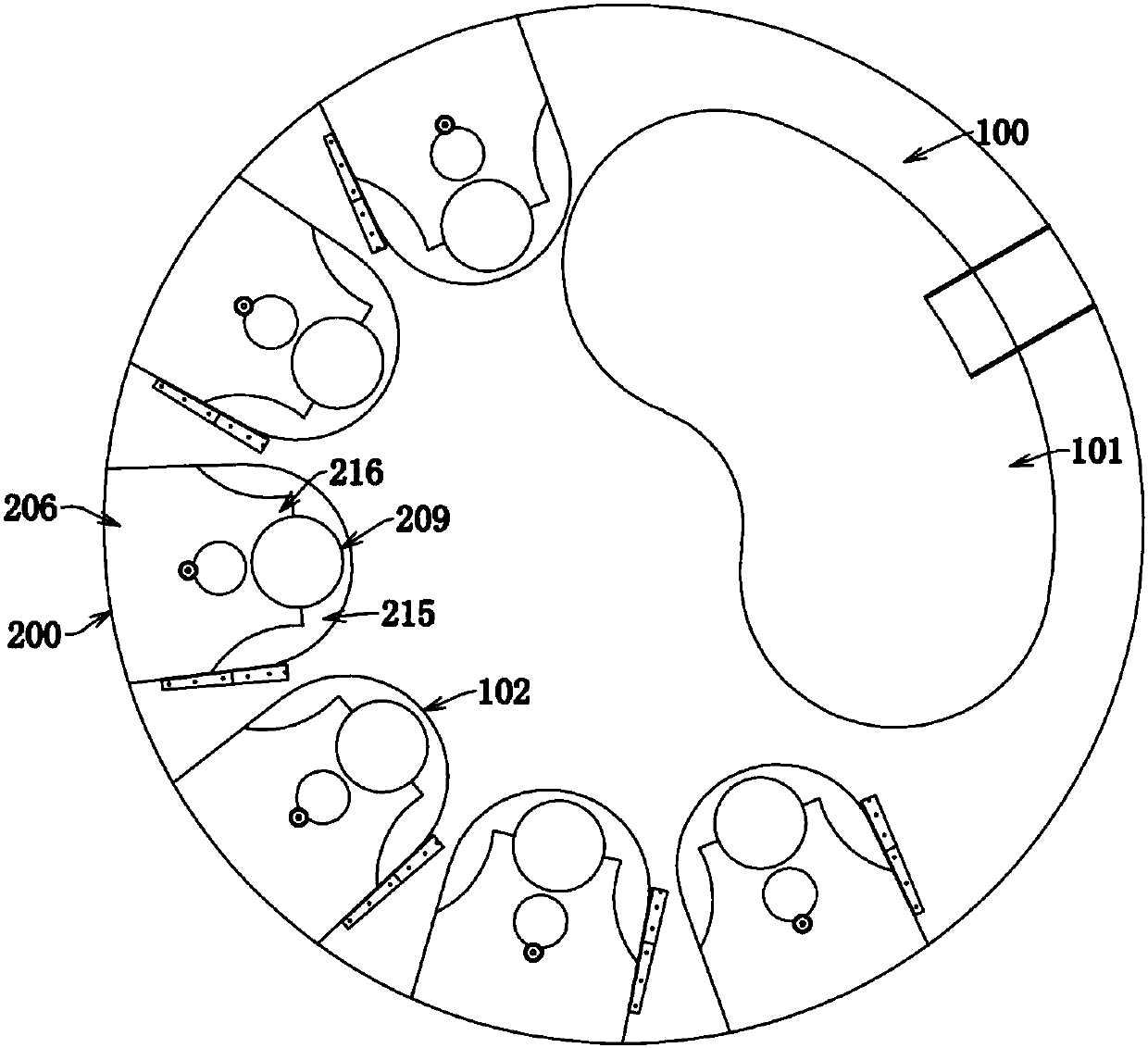

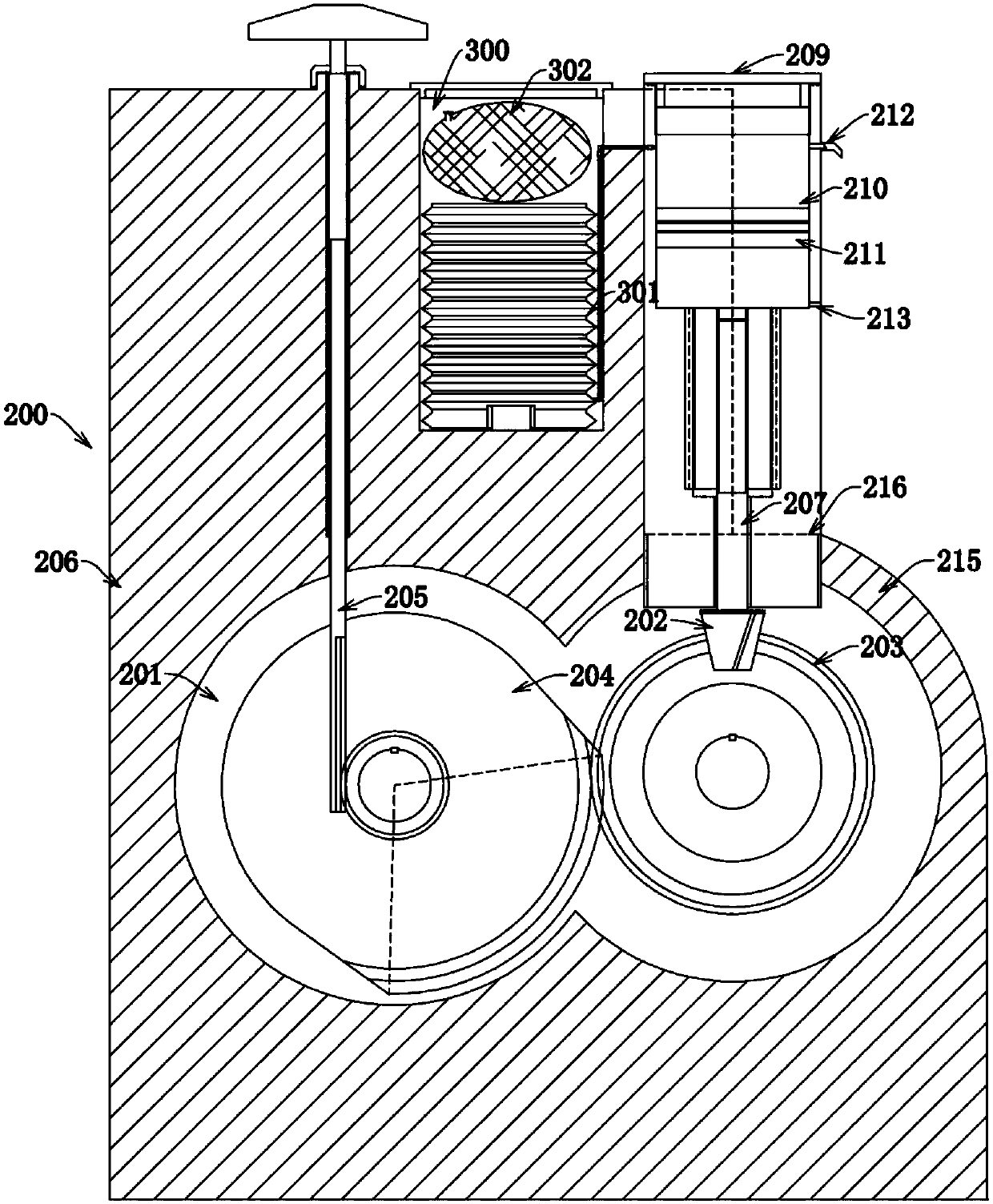

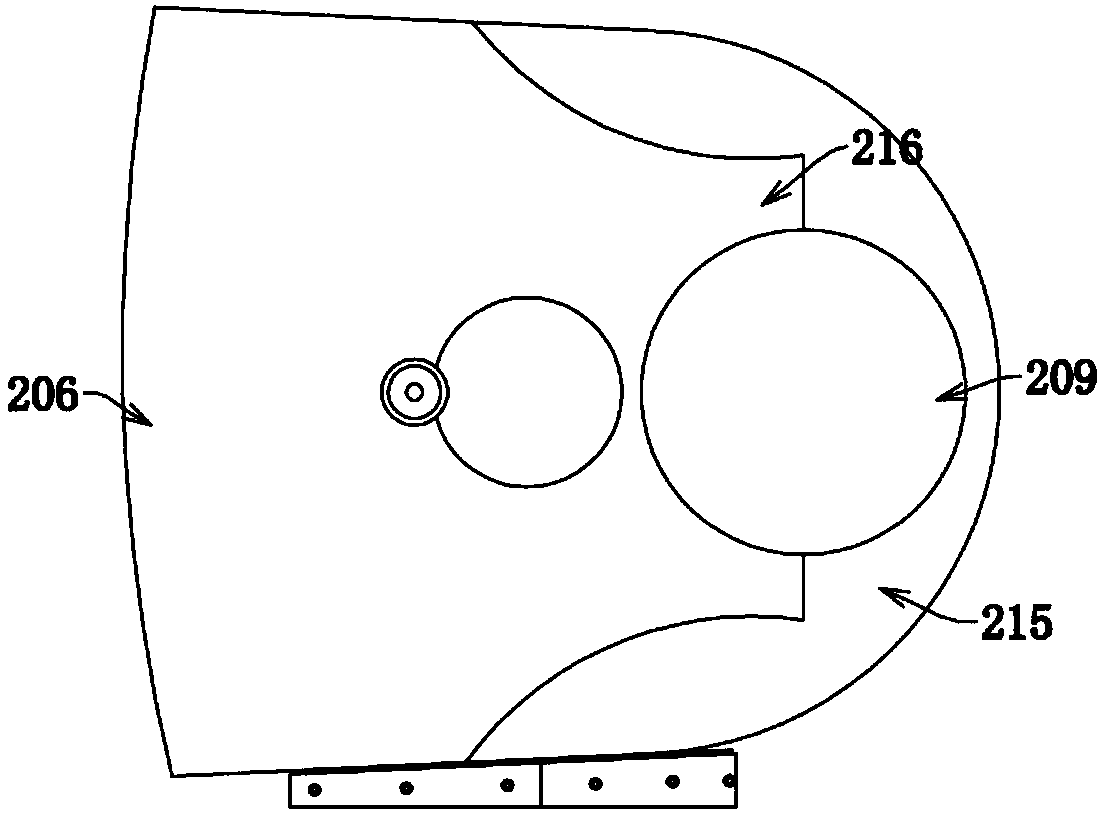

Rotating disc type reflux ratio controller

ActiveCN106492498AAccurate controller for reflux of rectification columnPrecise output controlDistillation regulation/controlComing outReflux

A rotating disc type reflux ratio controller comprises an external barrel, a liquid distributing tank, a separator plate, an adjusting rod, a rotating shaft, a supporting seat and a control motor. The external barrel is an enclosed structure and is composed of a lower cylinder and an upper head which are connected through a flange, and a bottom cap is a flat plate. The inside of the lower cylinder of the external barrel is divided by the separator plate from the center into two halves which are not communicated with each other. The upper center of the separator plate and the supporting seat are fixed together through a welding method. The liquid distributing tank is a cylinder with an upper opening. Half of the cylinder's side face is provided with small holes with phi 0.5-15, and the other half of the side face is imperforate. The two halves are separated by the use of two vertical lathes outside the cylinder. The rotating shaft passes through a bottom cap hole to be fixed with the bottom cap. The lower end of the rotating shaft, coming out of the bottom cap of the liquid distributor, is inserted into the supporting seat. The rotating shaft is connected with the adjusting rod to extend out of the external barrel through a sealing device so as to be connected with the control motor. The control motor drives the rotating shaft so as to rotate the rotational angle of the liquid distributing tank. Two sides of the separator plate of the bottom cap of the cylinder are respectively provided with a liquid outlet. One liquid outlet is a reflux port and the other liquid outlet is an output port.

Owner:杨顺立

Push type liquid or cream blending and mixing device for experimental use

ActiveCN107597013APrecise output controlAvoid the hassle of accurate meteringMixer accessoriesOutput deviceProcess engineering

The invention discloses a push type liquid or cream blending and mixing device for experimental use and solves the problems that metering all components has difficulty in control and an independent metering container needs to be depended on to meter the components when all the components are added into a composition. The push type liquid or cream blending and mixing device for experimental use comprises a blending disk, wherein a plurality of quantitative output devices are detachably connected to the blending disk, and the quantitative output devices are used for quantitatively outputting rawmaterials to a blending tank. All the quantitative output devices of the push type liquid or cream blending and mixing device disclosed by the invention can accurately control a fluid raw material output amount, and all material cabin boxes can serve as material storage devices and also can be quickly combined with a quantitative output control device and the blending disk; thus, trouble in continuously utilizing the metering container to meter accurately in a traditional fluid composition blending process is avoided; furthermore, output of all fluid can be quickly operated, and operation steps are greatly simplified.

Owner:浙江福赐德生物科技有限公司

Compound feed machining and feeding mechanism

InactiveCN108851146AAchieving mixing and stirringRealize quantitative dischargeFeeding-stuffGrain treatmentsPulp and paper industry

The invention discloses a compound feed machining and feeding mechanism. The mechanism comprises a mechanism body and a discharging hopper. The discharging hopper is arranged at the bottom of the mechanism body. A clamping groove is formed in the discharging hopper, the mechanism body is movably clamped to the clamping groove, the top of the mechanism body is provided with a motor and a feeding inlet, a stock bin is arranged inside the mechanism body, a rotating shaft is arranged at the bottom of the motor, the rotating shaft extends into the stock bin, a stirring rod is fixedly arranged on the rotating shaft, a protrusion is fixedly arranged at the bottom end of the rotating shaft, a mixed bin is arranged at the bottom of the stock bin, a discharging outlet is formed in the top of the mixed bin, a baffle is arranged at the bottom of the discharging outlet, the baffle is sleeved with a connecting rod, a stirring mechanism is arranged on the connecting rod, and an embedded groove is formed in the top end of the connecting rod. The rotating shaft and the connecting rod are movably clamped through the protrusion and the embedded groove, mixed stirring of feed and breaking of caked feed can be achieved, the baffle can be driven to move up and down conveniently, and quantified feed discharging can be achieved.

Owner:ANHUI GAOLAOZHUANG ECOLOGICAL AGRI TECH CO LTD

Packaging device for seed packaging machine

PendingCN108557125AQuality is easy to controlSmall quality errorSolid materialPackaging protectionNatural statePackaging machine

The invention belongs to the technical field of seed packaging equipment and particularly discloses a packaging device for a seed packaging machine. The packaging device comprises a workbench, and theworkbench is provided with a discharging stage, a supporting table, a supporting rod and a balance plate. The discharging stage is internally provided with a cavity structure, and a supporting blockis arranged in the cavity structure; when a first spring is in a natural state, the supporting block is enabled to protrude the cavity structure, and a retaining plate is positioned in a slide cavity,and the supporting block is constantly abutted against the lower end of the balance plate. A fixing plate used for weight placement is arranged at one end, away from the supporting table, of the balance plate. A placement plate for placement of packaging boxes is arranged at the other end of the balance plate and positioned above the supporting block. The packaging device is mainly used for seedpackaging, and the problem of low seed weighing efficiency caused by errors in a weighing process and low manual weighing speed is solved.

Owner:重庆众点农业有限公司

Intelligent tubular oppositely-opened type stirring machine

InactiveCN105688728AQuality assuranceGuaranteed molding rateTransportation and packagingMixer accessoriesCouplingSpiral blade

The invention discloses an intelligent tubular oppositely-opened type stirring machine which comprises a base, a multi-stage stirring pipe device and an air compressor.The multi-stage stirring pipe device is composed of a first-stage stirring pipe device body and a second-stage stirring pipe device body.The first-stage stirring pipe device body comprises a first-stage stirring pipe.The rear end of the first-stage stirring pipe is connected with a speed reduction electric motor through an elastic coupler.The first-stage stirring pipe is fixed to the base and communicated with a high-position bin.The second-stage stirring pipe device body comprises a second-stage stirring pipe.The second-stage stirring pipe is connected with the speed reduction electric motor through an elastic coupler.The discharge port of the first-stage stirring pipe is communicated with the feed port of the second-stage stirring pipe.Binder feeding systems are arranged on the first-stage stirring pipe and the second-stage stirring pipe respectively.Spiral blades are arranged in the first-stage stirring pipe and the second-stage stirring pipe respectively.A PLC electric appliance control cabinet is arranged on the base.The intelligent tubular oppositely-opened type stirring machine is reasonable in design and arrangement, the dry-to-wet ratio of clinker can be designed according to temperature differences of seasons and the humidity of air, and the amounts of dry materials, water and binder are arranged according to the proportion.

Owner:ANHUI CHENGUANG HIGH WEAR RESISTANCE TECH CO LTD

Rotation angle detection method and device thereof

ActiveUS20210333082A1Improve measurement accuracyReduce influenceAngles/taper measurementsElectronic commutation motor controlPhysicsMotor shaft

The present invention provides a rotation angle detection method and device thereof. The method includes calculating an estimated value of a rotation angle of a motor shaft during rotation according to a second rotation angle; determining an actual range of the rotation angle according to the estimated value of the rotation angle and a detection error of the second angle sensor; determining optional values of the rotation angle based on a relative relationship between a first rotation angle and the estimated value; determining an actual rotation angle of the motor shaft, based on a value falling within the actual range of the rotation angle among the optional values, and determining an actual rotation angle of the output shaft according to the actual rotation angle of the motor shaft. The present invention can improve the measurement accuracy of the rotation angles of the output shaft of the rotating mechanism.

Owner:UBTECH ROBOTICS CORP LTD

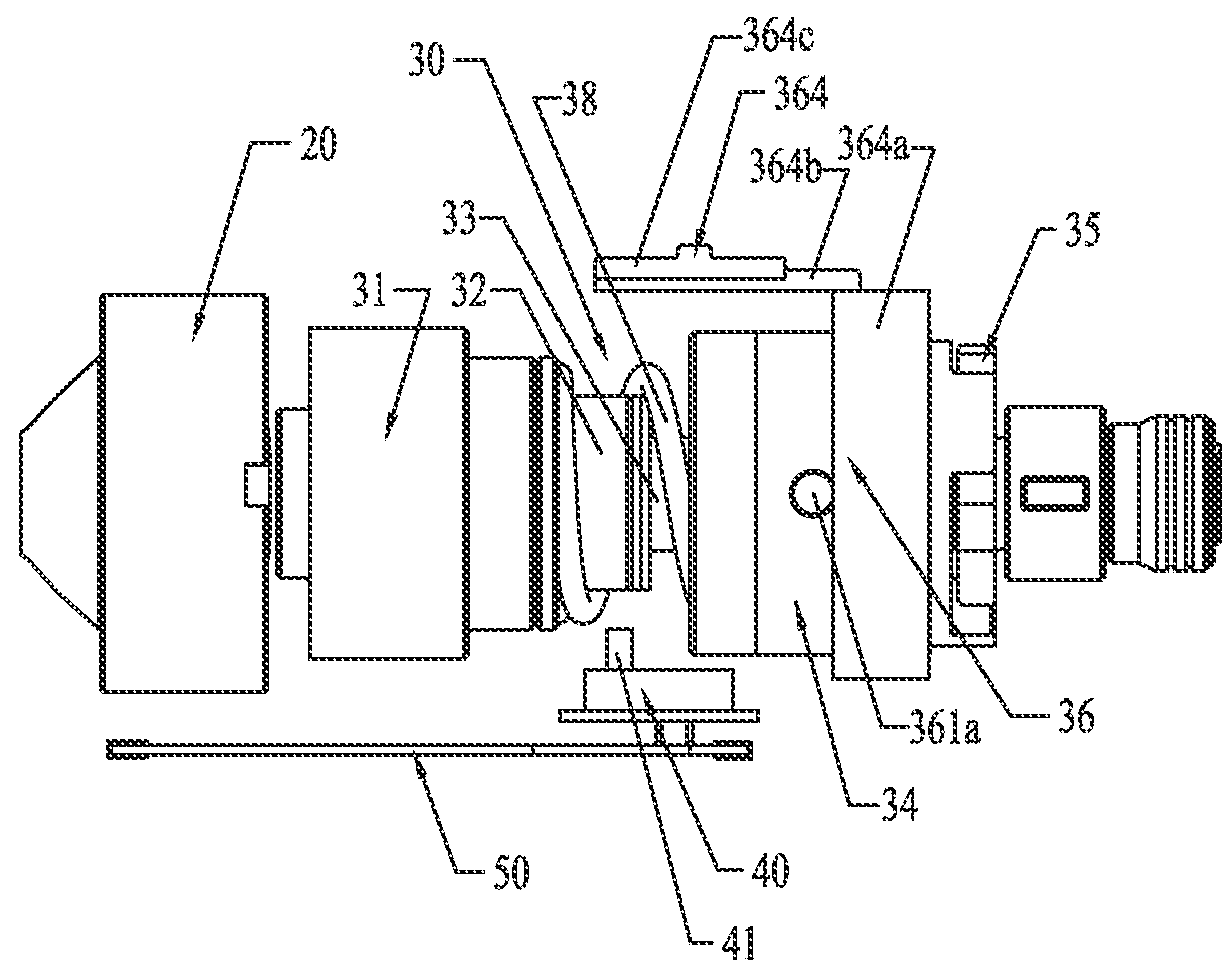

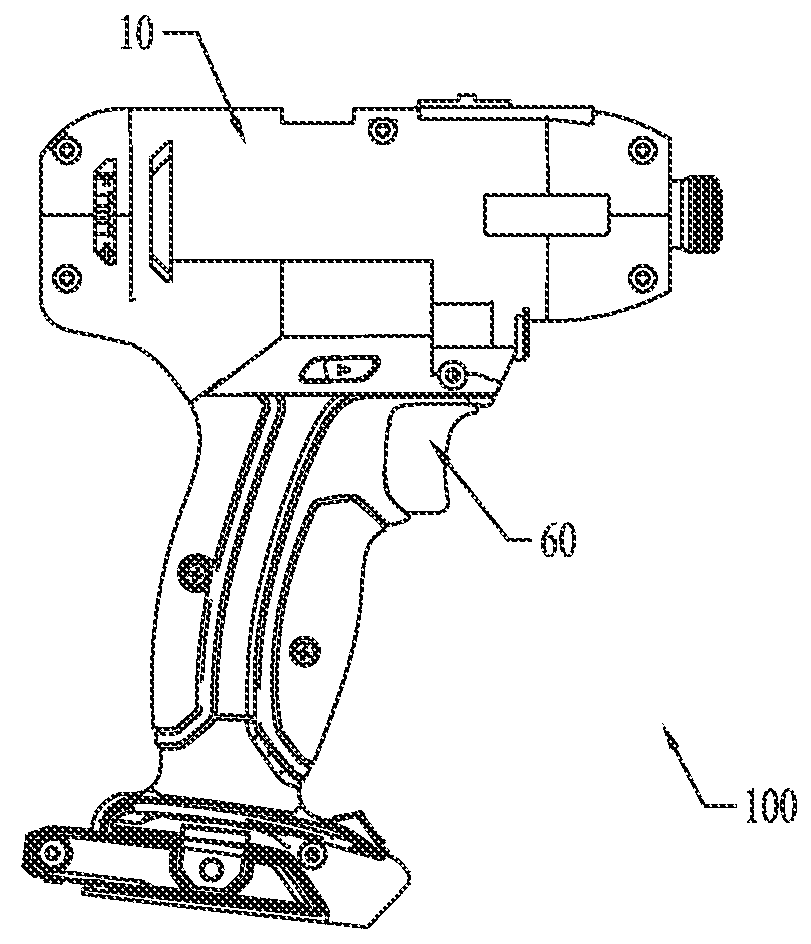

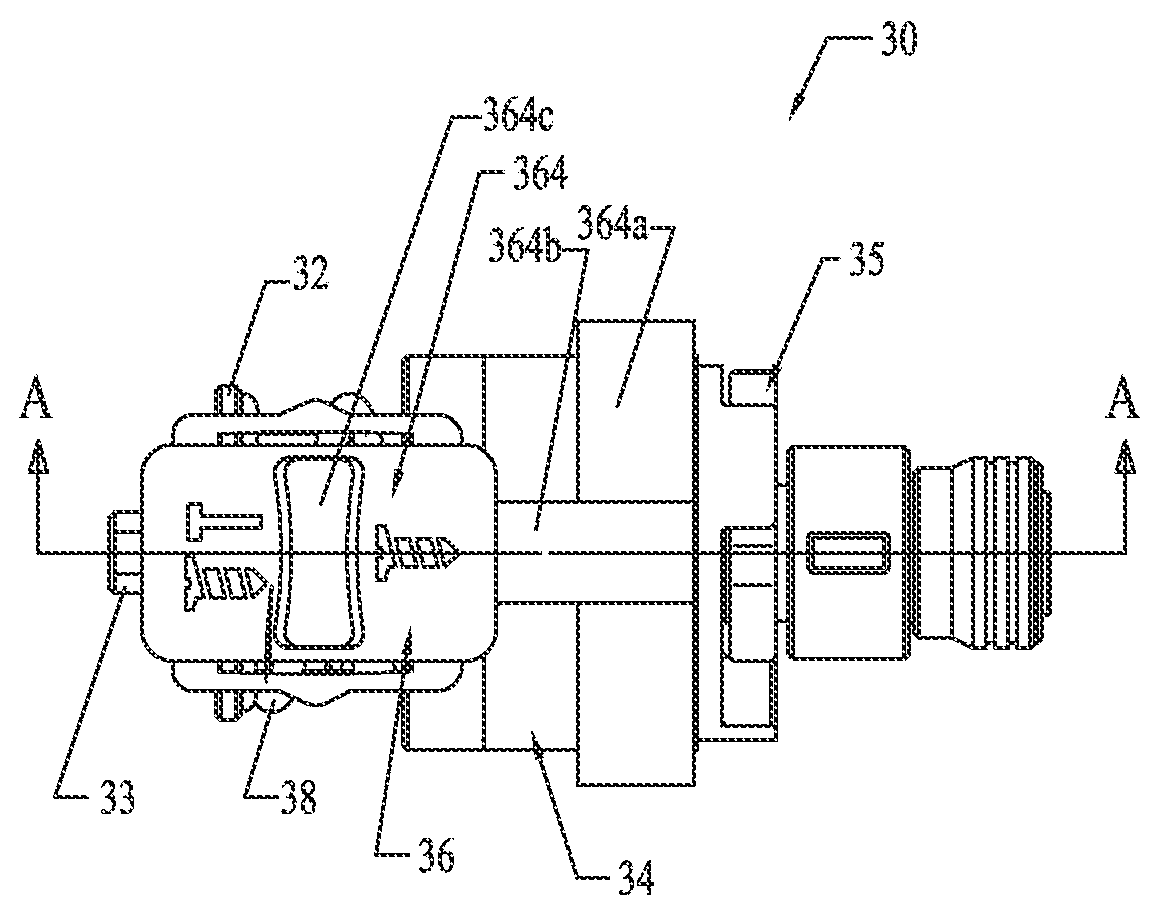

Multi-purpose electric tool and control thereof

A multi-purpose electric tool has a motor, an impact block, a detection assembly configured to detect the position and the movement state of the impact block, and a main control circuit board configured to control whether the motor is powered off upon reaching a preset state according to the detected information of the detection assembly. In the control method, the detection assembly feeds back the detected information to the main control circuit board, if the impact block is not impacting reciprocatingly, the main control circuit board performs torque control according to whether the preset state is reached; and if the impact block is impacting reciprocatingly, the main control circuit board enables the motor to output in a normal mode which does not limiting the current.

Owner:CHERVON HK LTD WANCHAI

Production device of thin film switch

InactiveCN109887778AImprove cooling effectAvoid insufficientElectric switchesMembrane switchEngineering

The invention discloses a production device of a thin film switch. The production device comprises an operation table, a mounting frame, a positioning assembly, a discharging assembly and a base; themounting frame is arranged on the operation table; the positioning assembly used for positioning an injection mold is arranged on a horizontal section of the mounting frame; the discharging assembly used for controlling the injection mold discharging is arranged at the lower end of a positioning frame; a discharging pipe is arranged at the lower end of a storage tank; the feeding pipe is arrangedon the side surface of the storage tank; and the base is a below the operation table. The invention further discloses a production method of the thin film switch; the method comprises the following steps that a circuit film finished product is placed in the injection mold, and the production device is started for carrying out injection molding, de-molding treatment, detection, packaging and storage. By virtue of coordination of the positioning assembly and the discharging assembly, the injection molding operation is simple, manual fixation of the mold is not needed, the labor is saved, and theworking efficiency is high; and after the injection molding is finished, a two-way fan is used for discharging air, an air outlet pipe is aligned with the injection mold for air delivering, so that the mold is cooled, the mold cooling is accelerated, and the production speed is increased.

Owner:ZHONGSHAN JIEXIN TECH SERVICES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com