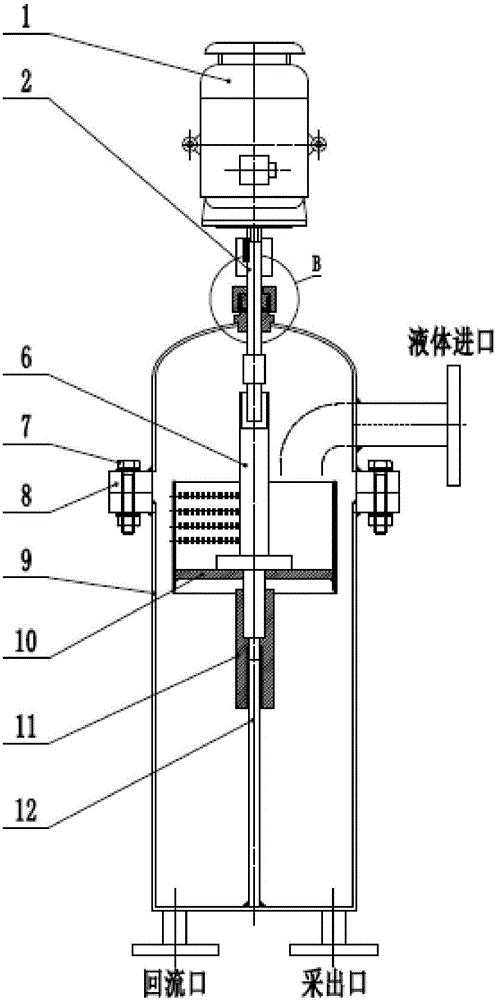

Rotating disc type reflux ratio controller

A reflux ratio controller, turntable technology, applied in the direction of distillation adjustment/control, chemical instruments and methods, distillation separation, etc., can solve the problems of immature small flow automatic control technology, unstable intermittent tower flow, complicated devices, etc. Achieve the effect of simple structure, stable flow and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

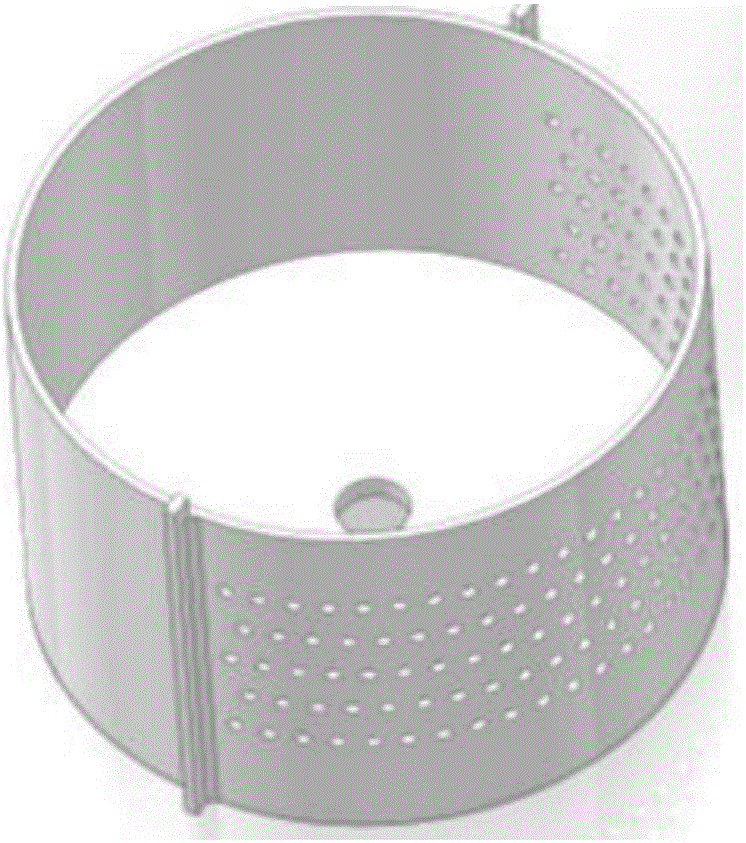

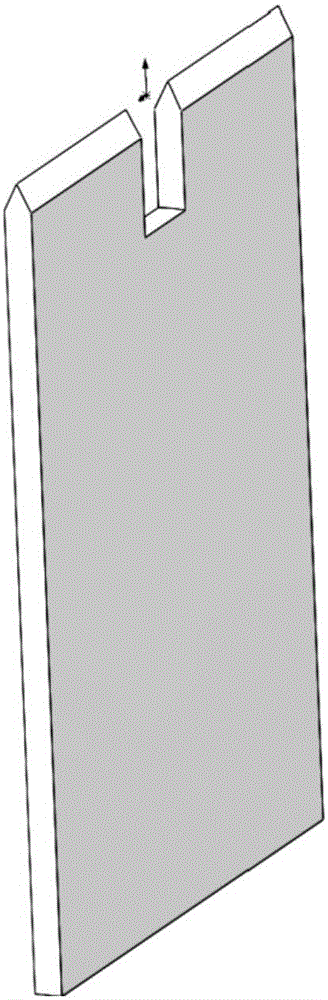

[0022] Example 1 The specification of the reflux ratio controller is 250-4000, the diameter of the outer barrel is φ273×6, the diameter of the turntable is φ219×4, the height of the turntable is 150, the outlet hole is φ3, the number of holes is 150, the material is 304, and the designed liquid flow rate is 400-4000L / h .

Embodiment 2

[0023] Example 2 The specification of the reflux ratio controller is 300-5000, the diameter of the outer barrel is φ325×6, the diameter of the turntable is φ273×4, the height of the turntable is 170, the outlet hole is φ3, the number of holes is 200, the material is 316 or fluoropolymer material coating, the design Liquid flow 500~5000L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com