Automatic mixing device for pigment

A kind of paint and automatic technology, applied in the direction of decorative art, painting tools, etc., can solve the problems of automatic color recognition, difficult to achieve accurate color matching, etc., to achieve precise output control, high sensitivity, and reduce human errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

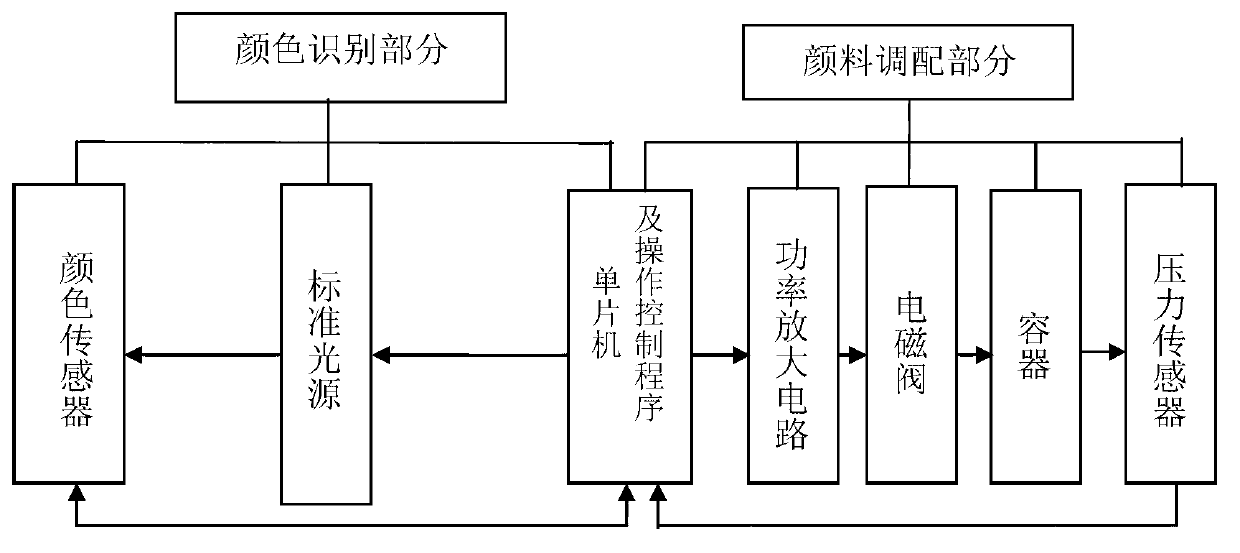

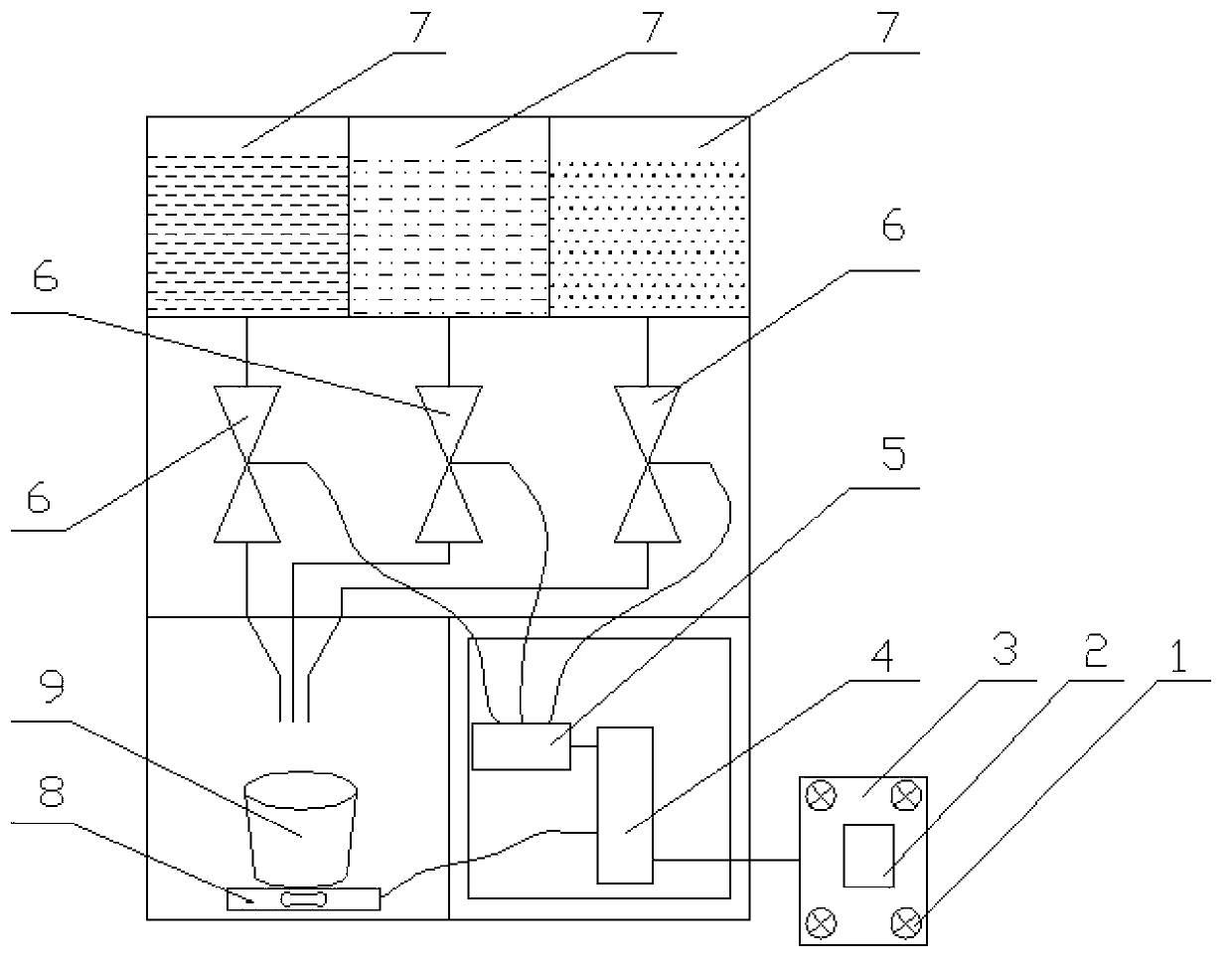

Embodiment 1

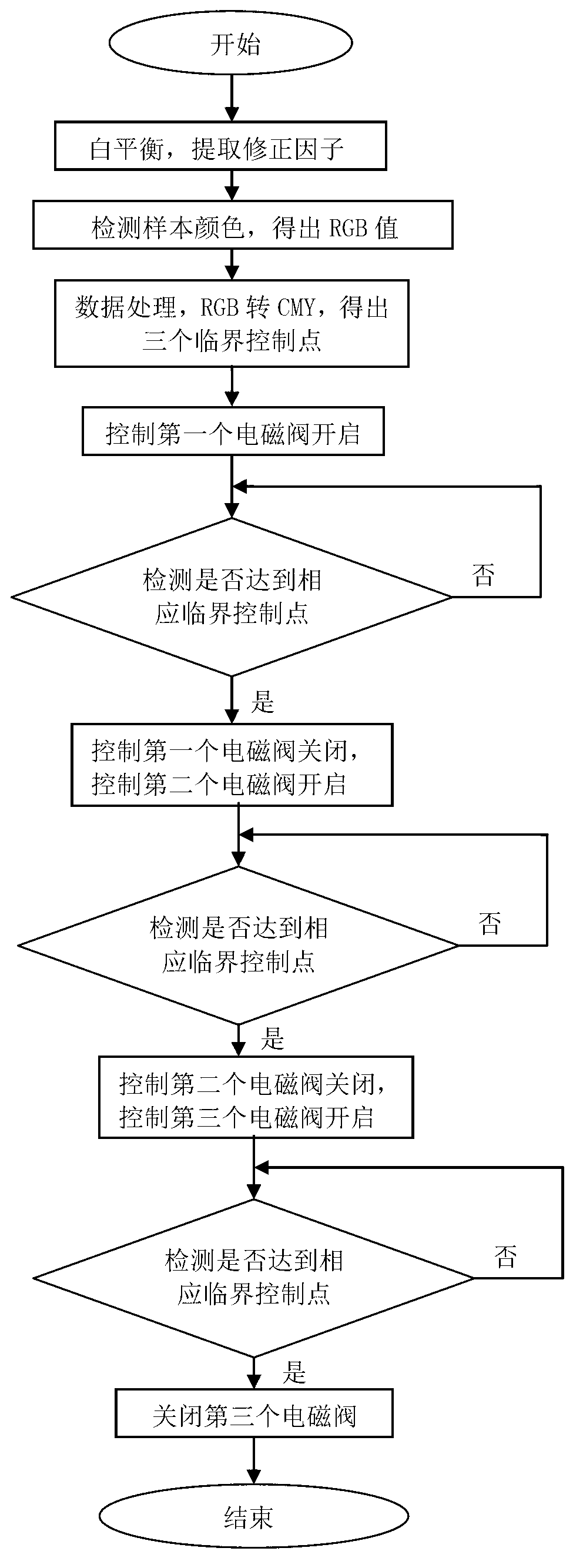

[0029] according to the above figure 2 and image 3 As shown, an automatic pigment blending device was prepared, in which the standard light source is four bright white LEDs, and the color sensor adopts the existing TCS230 chip. The single-chip microcomputer adopts the STC89C52 single-chip microcomputer, and the single-chip microcomputer 3 is powered by a unified 5V DC power supply. The power amplifier circuit adopts triode amplification and intermediate relay output. The model of the selected solenoid valve is 2W-08. mm and valve body material is brass, powered by 12V DC power supply, the pressure sensor is a resistance sensor, the container is airtight and does not react with the pigment, the operation control program of the single-chip microcomputer is: start → white balance, extract correction factor → detect sample color , get the RGB value → data processing, convert RGB to CMY, get three critical control points → control the opening of the first solenoid valve → detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com