Pneumatic impact system with digital display screen

A technology of air supply system and liquid crystal display screen, applied in the direction of hypodermic injection devices, etc., can solve the problems of mechanical failure, inconvenient clinical use, complicated internal design of the power system, etc., and achieve the effect of convenient clinical use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

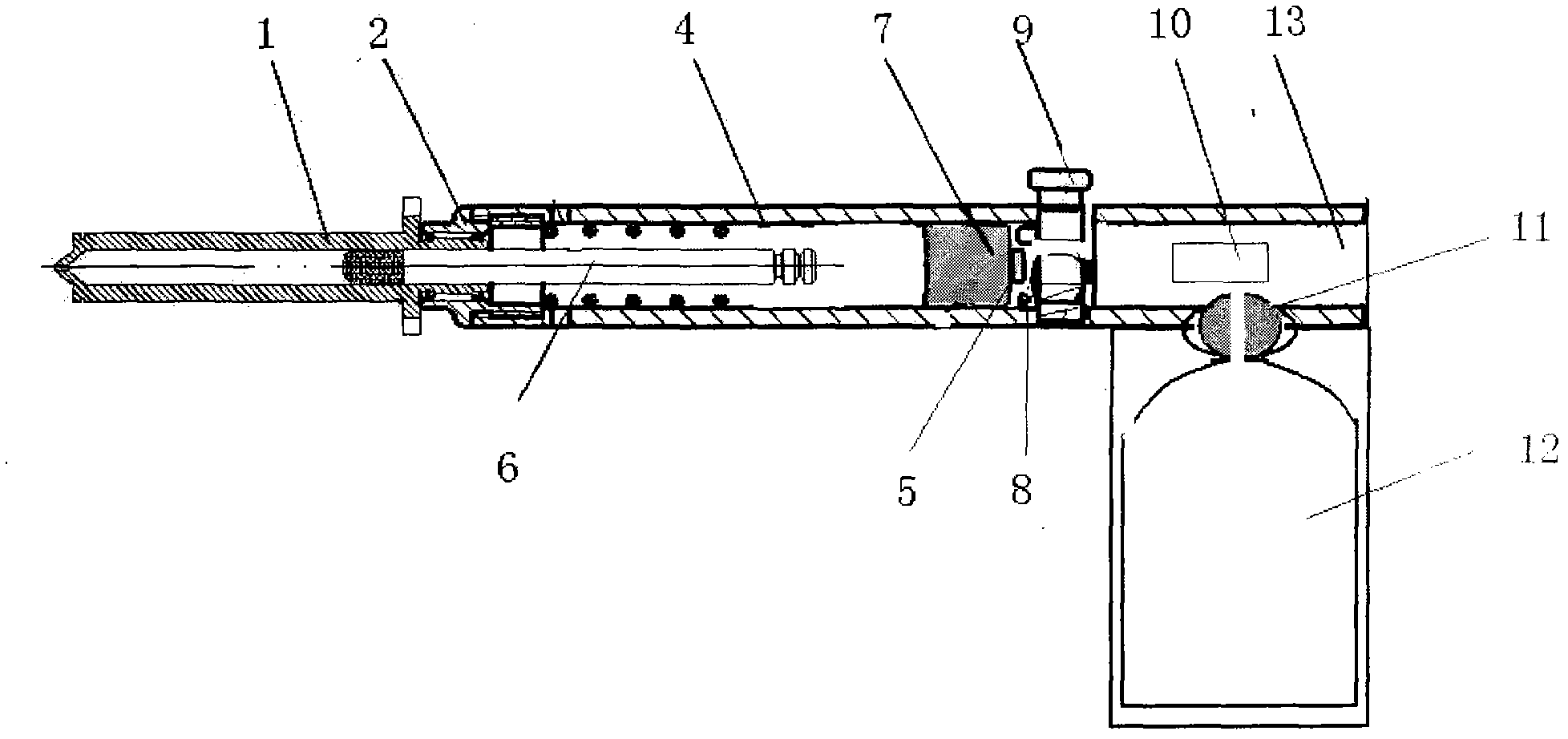

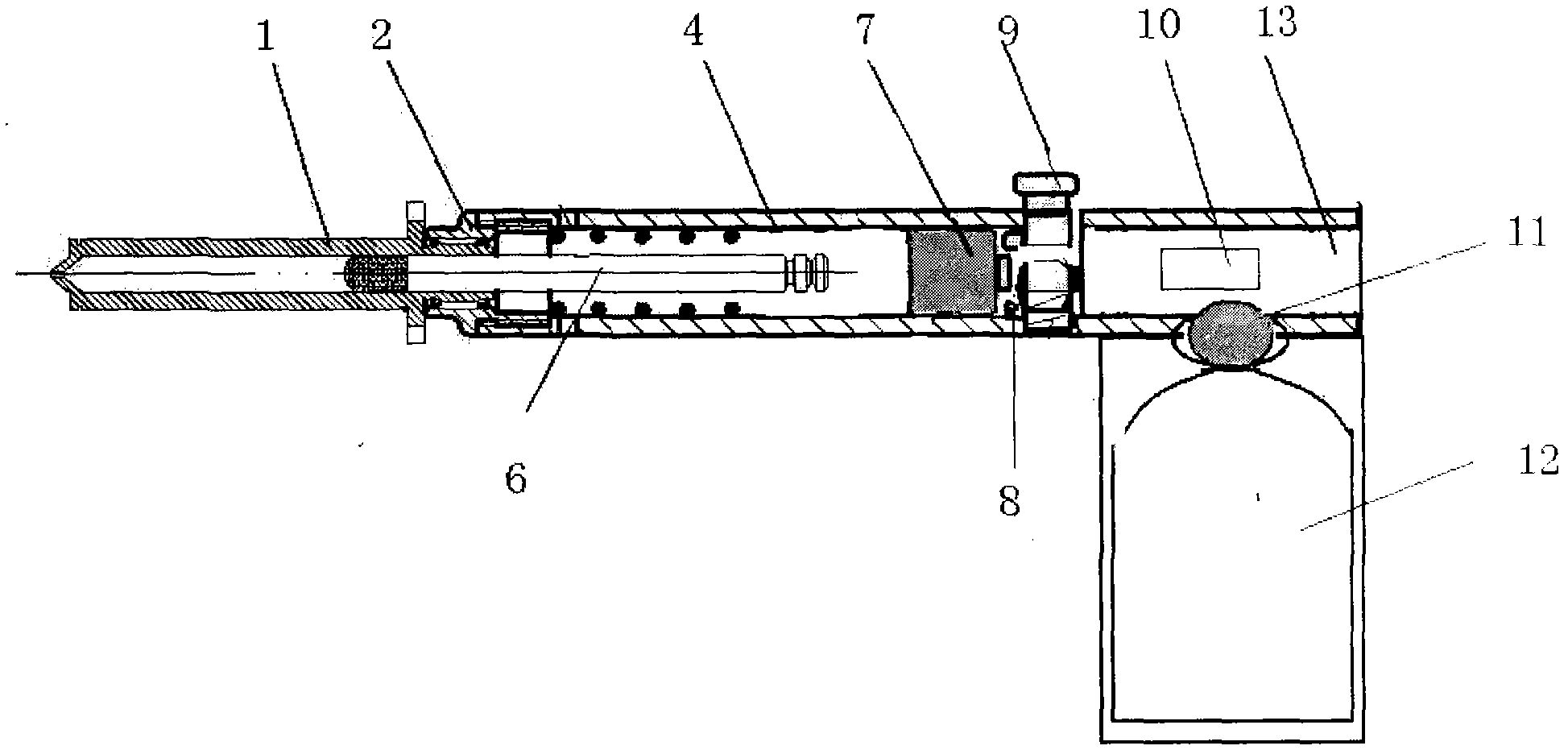

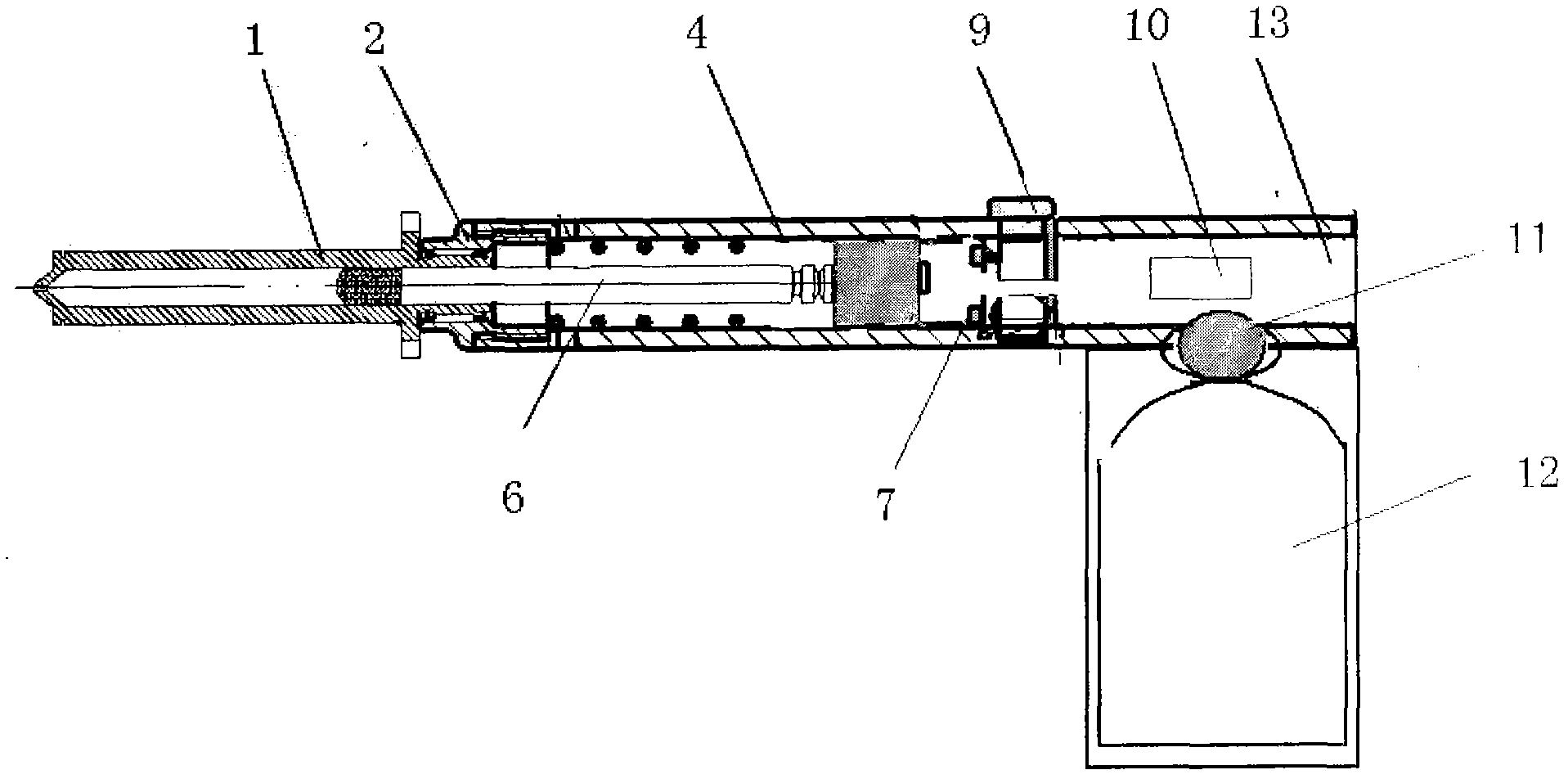

[0037] Specific embodiment 1. Pneumatic impact system with digital display screen is used for liquid injection

[0038] figure 1 The medicine is pre-injected into the syringe 1, installed on the syringe 4, the valve 11 is opened, the gas from the compressed gas cylinder 12 is output to the gas storage chamber 13, and the digital display screen 10 connected to the pressure sensor displays the pressure of the gas storage chamber. When the pressure on the display screen 10 reaches the required pressure, close the valve 11, and the system is in the state of figure 2 The status shown is: press the activation button, the channel of the button valve core is connected with the air outlet of the gas storage chamber, when the pressure exceeds the suction force of the magnet on the impact piston, the impact piston generates an instantaneous explosive force, and the impact on the syringe push rod does work, such as image 3 As shown, the button 9 automatically resets under the action o...

specific Embodiment 2

[0039] Specific embodiment two, the pneumatic impact system with digital display screen is used for solid powder injection

[0040] Figure 4 The numbered powder 4 is pre-loaded into the medicine tube, sealed up and down with the rupture film 8, connected with the excitation button 9 through the threaded port, the valve 11 is opened, the gas of the compressed gas cylinder 12 is output to the gas storage chamber 13, and the digital display screen 10 connected to the pressure sensor Display the pressure of the air storage chamber, when the pressure on the digital display screen 10 reaches the required pressure, close the valve 11, in such as Figure 5 The state shown is: press the activation button 9, the button spool channel is connected with the air outlet of the gas storage chamber, the high-pressure gas is released instantly, and the blowing powder is accelerated to the powder injection chamber 1 through the acceleration tube, and the powder is instantly injected into the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com