Pre-mixing type spiral powder feeding device

A screw feeding device and pre-mixing technology, applied in packaging, mixers, transportation and packaging, etc., can solve the problems of low modification efficiency and achieve the effects of improving modification efficiency, shortening modification mixing time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

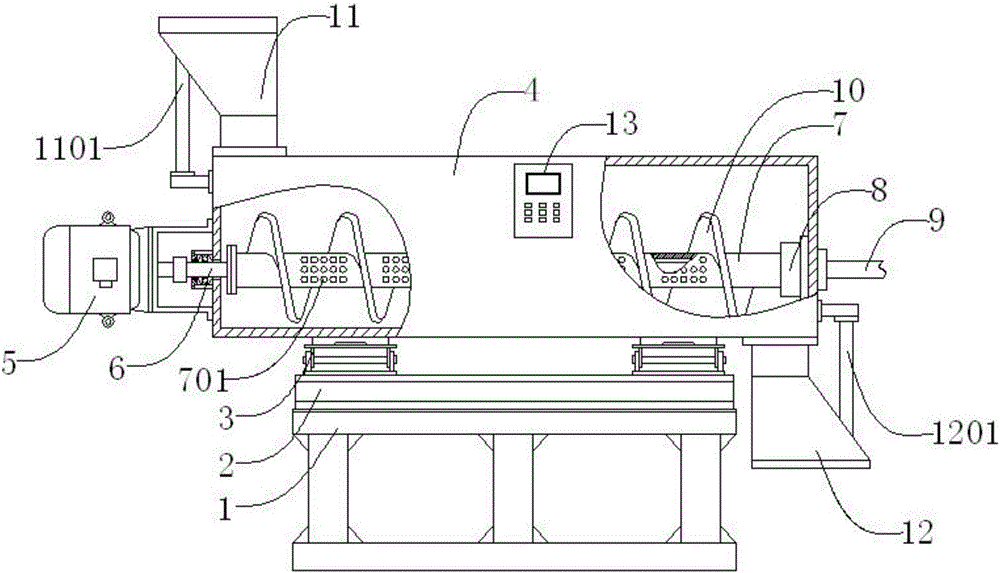

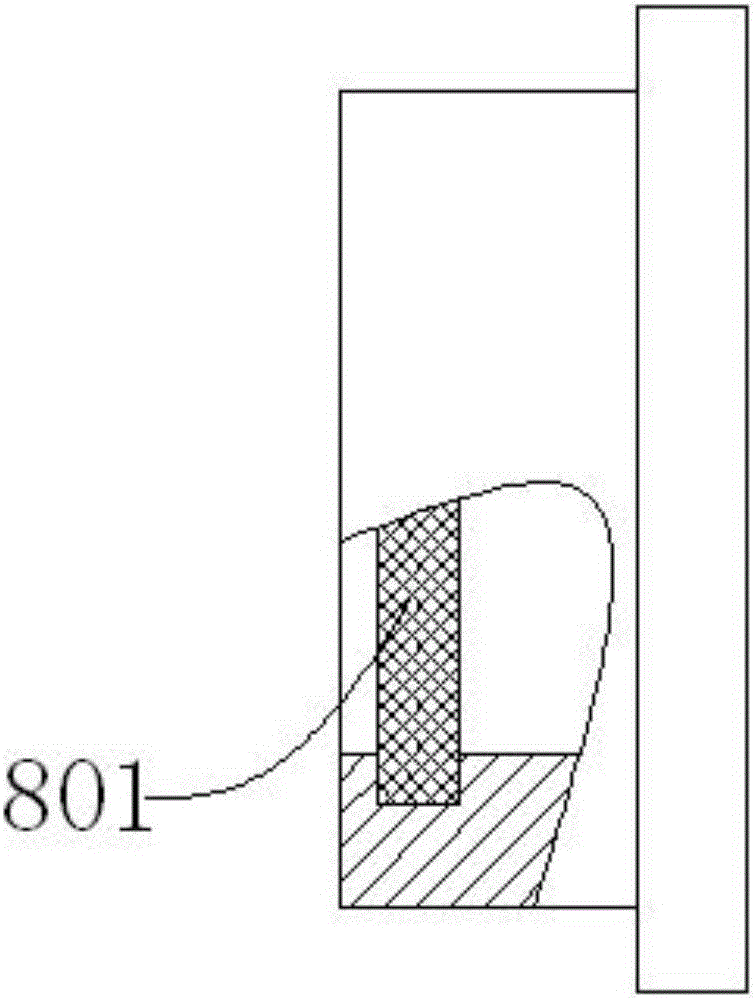

[0023] Such as figure 1 , figure 2 As shown, a premixed powder screw feeding device includes a frame 1, a flat platform 2, a load cell 3, a box body 4, a motor 5, a rotating shaft 6, a hollow shaft 7, a sealing seat 8, a blowpipe 9, a screw The impeller 10, the feed nozzle 11, the discharge nozzle 12, the controller 13, the flat platform 2 is located at the upper end of the frame 1, the flat platform 2 is screwed to the frame 1, and the load cell 3 is located at the The upper end of the flat platform 2, the load cell 3 is screwed to the flat platform 2, the box 4 is located at the upper end of the load cell 3, the box 4 is screwed to the load cell 3, and the motor 5 is located on the left side of the box body 4, and the motor 5 is connected to the box body 4 by threads. The rotating shaft 6 runs through the box body 4 and is located on the right side of the motor 5. The rotating shaft 6 is connected to the box body 4 in rotation and connected to the motor 5 Tightly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com