Control system and control method for novel visible light curing 3D printer

A 3D printer and control system technology, applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of complex structure, complicated control process and poor printing accuracy of visible light curing 3D printers, so as to improve printing speed and printing accuracy. High positioning accuracy, high control accuracy, and simple printing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

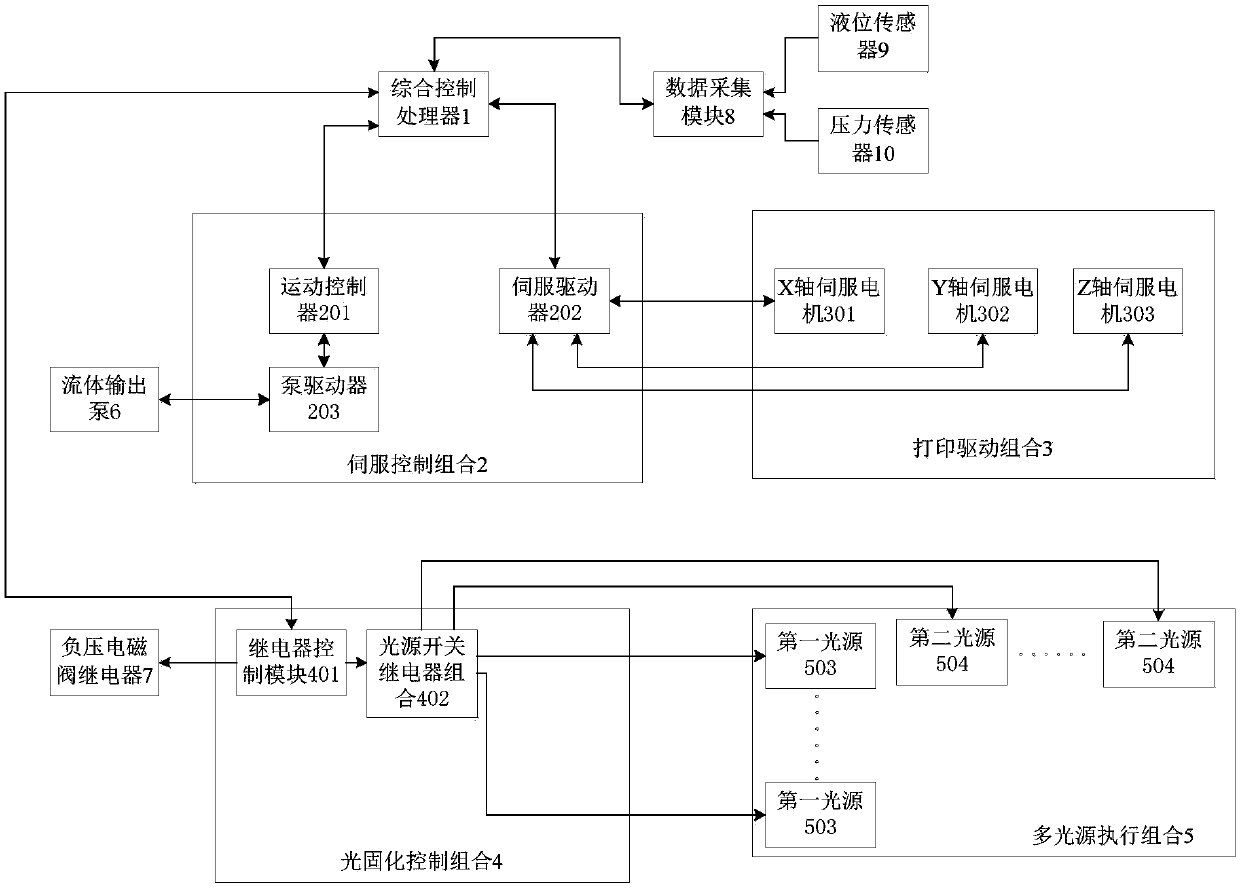

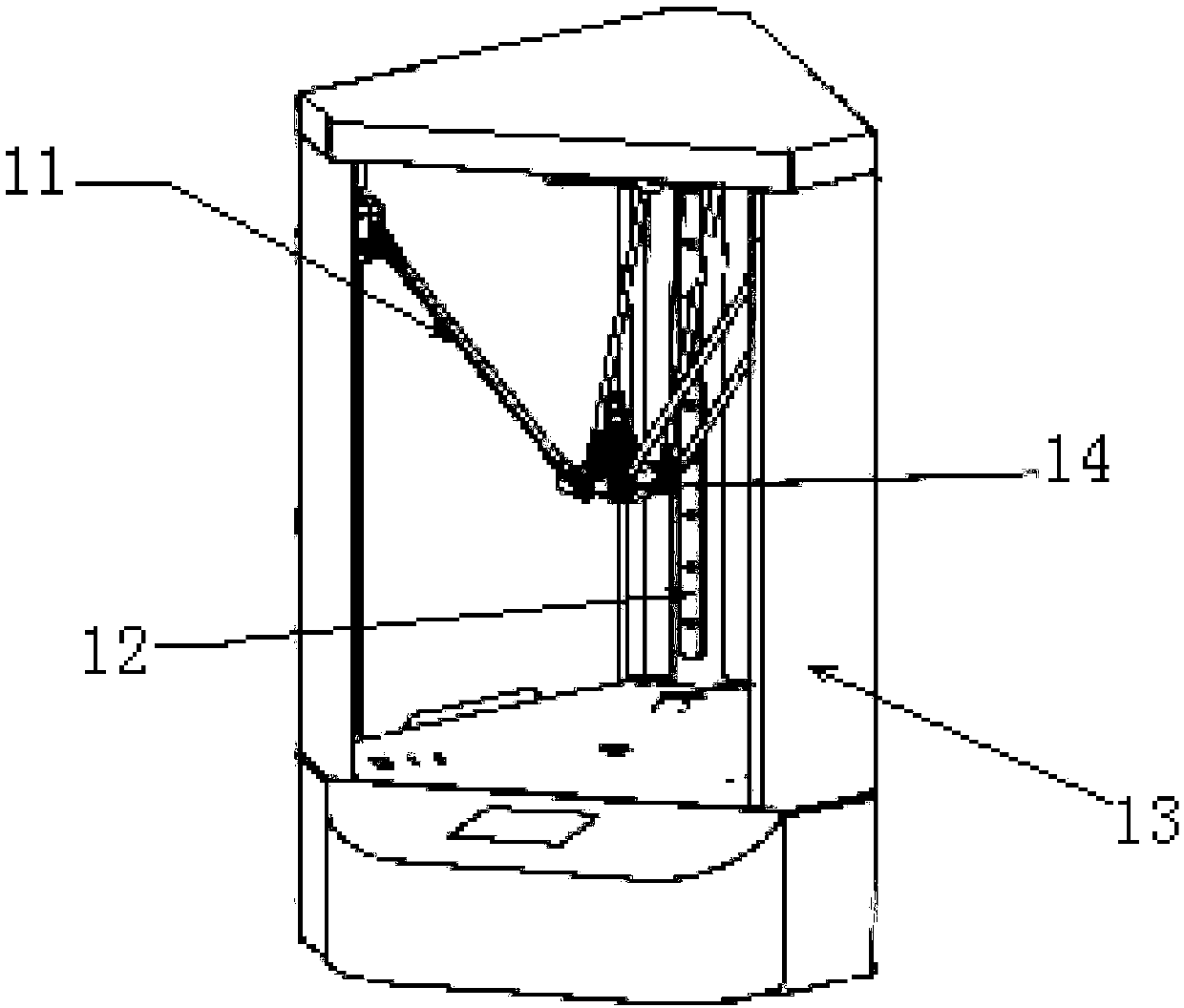

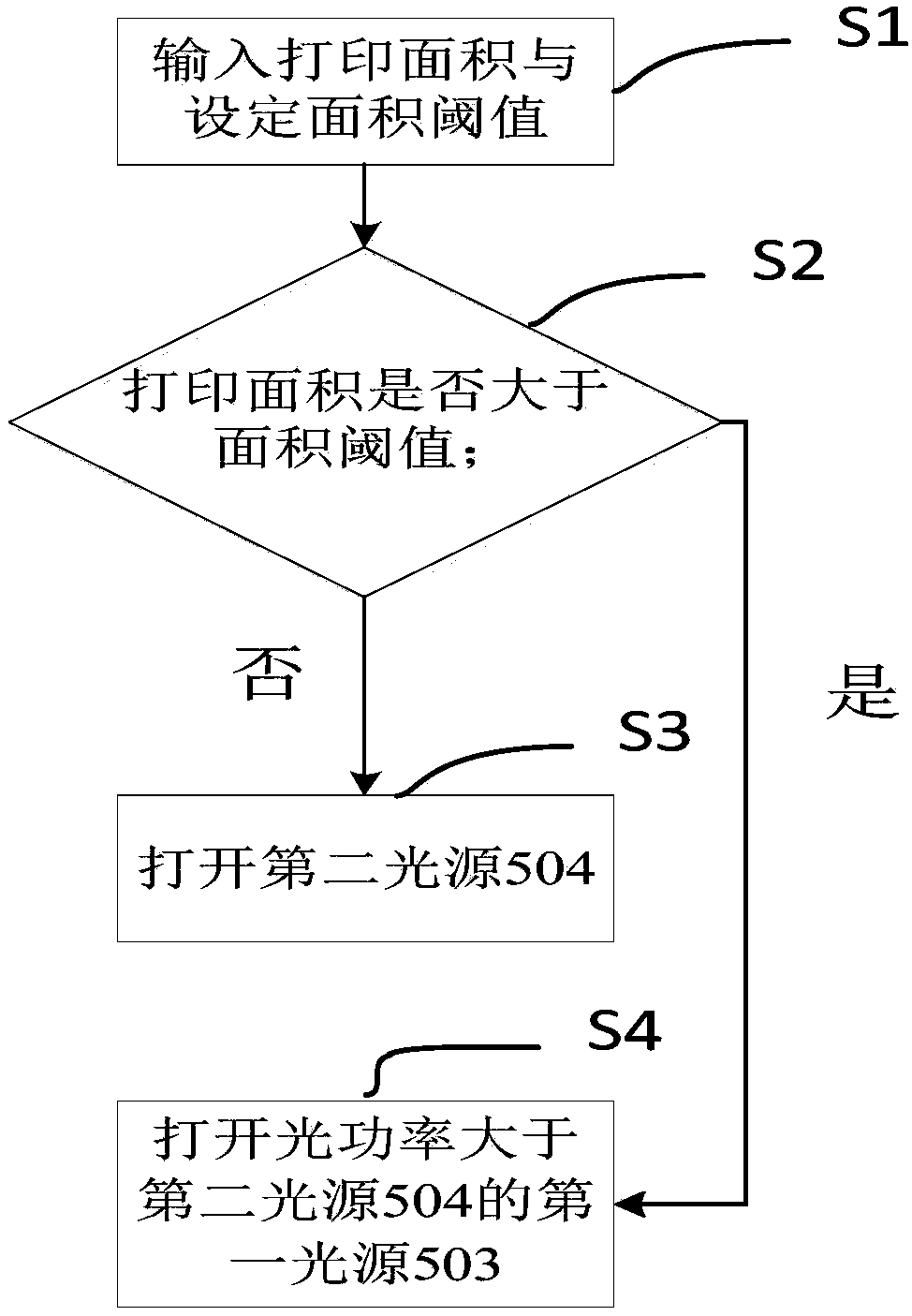

[0054] Such as figure 1 , figure 2 As shown, a new control system of a visible light curing 3D printer is applied to a 3D printer including a print head 14. The control system includes an integrated control processor 1, a servo control combination 2, a printing drive combination 3, and a photocuring control combination 4 Execute combination 5 with multiple light sources;

[0055] The comprehensive control processor 1 communicates with the servo control combination 2 and the photocuring control combination 4 respectively, and is used for linkage control of the servo control combination 2 and the photocuring control combination 4; the comprehensive control processor 1 is specifically a computer, through a data bus Communicate with the servo control combination 2 and the photocuring control combination 4;

[0056] The servo control combination 2 is connected to the printing drive combination 3, and is used for multi-axis servo motion control on the printing drive combination 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com