Micro lubricating device and using method thereof

A micro-lubrication and integrated technology, which is applied in the field of lubrication, can solve the problems of low utilization rate of lubricating oil and poor atomization effect, and achieve the effects of significant atomization effect, good atomization effect and reduction of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

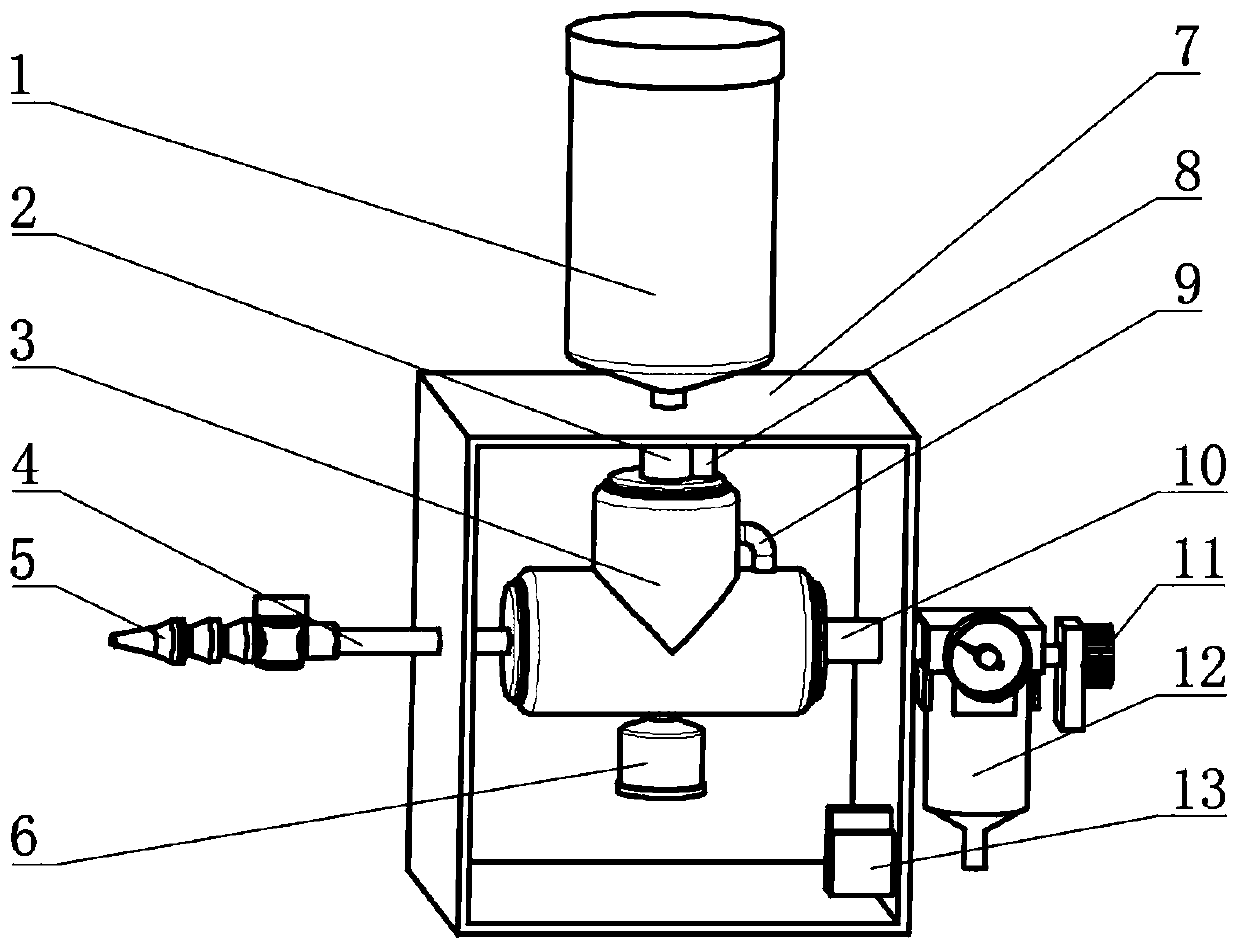

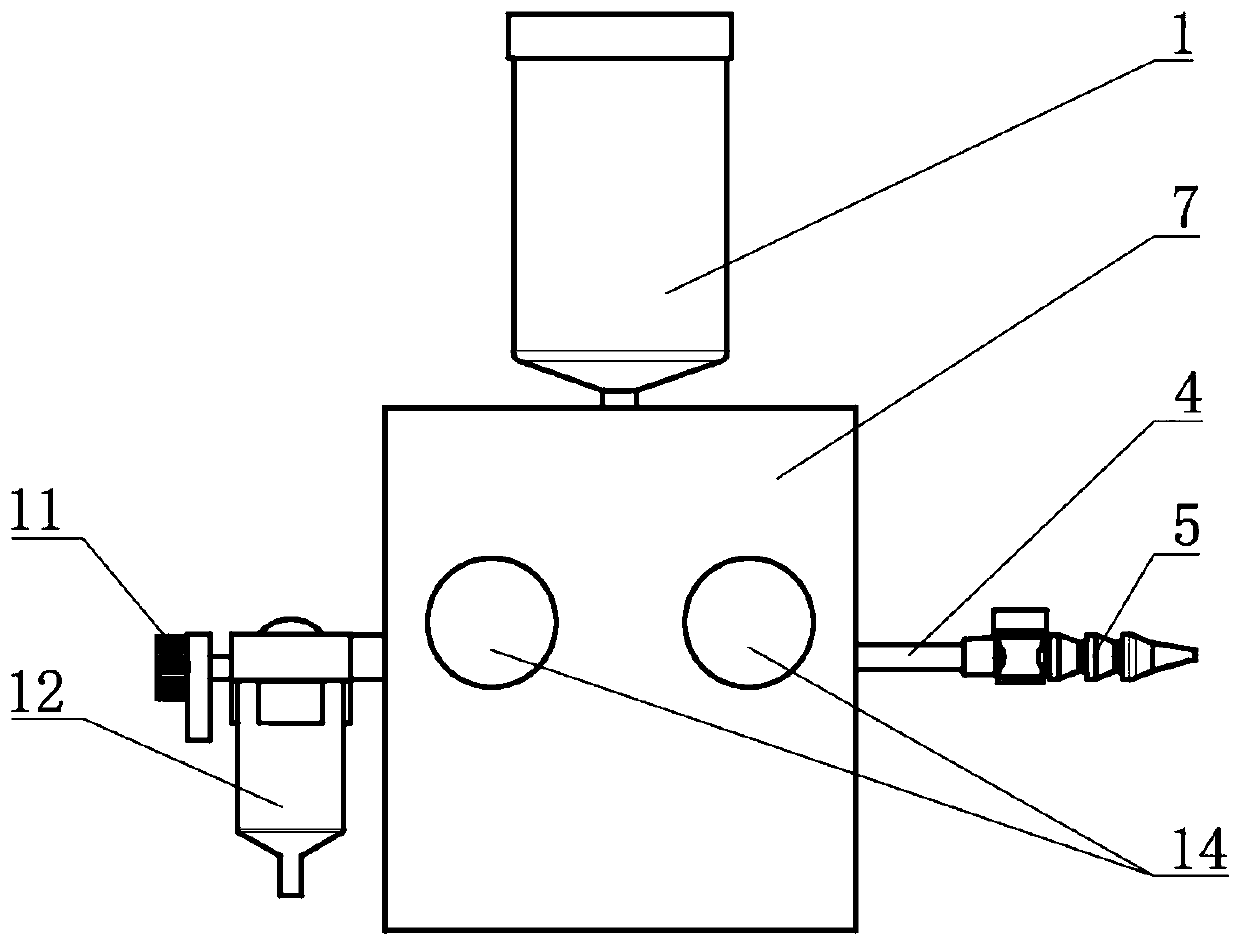

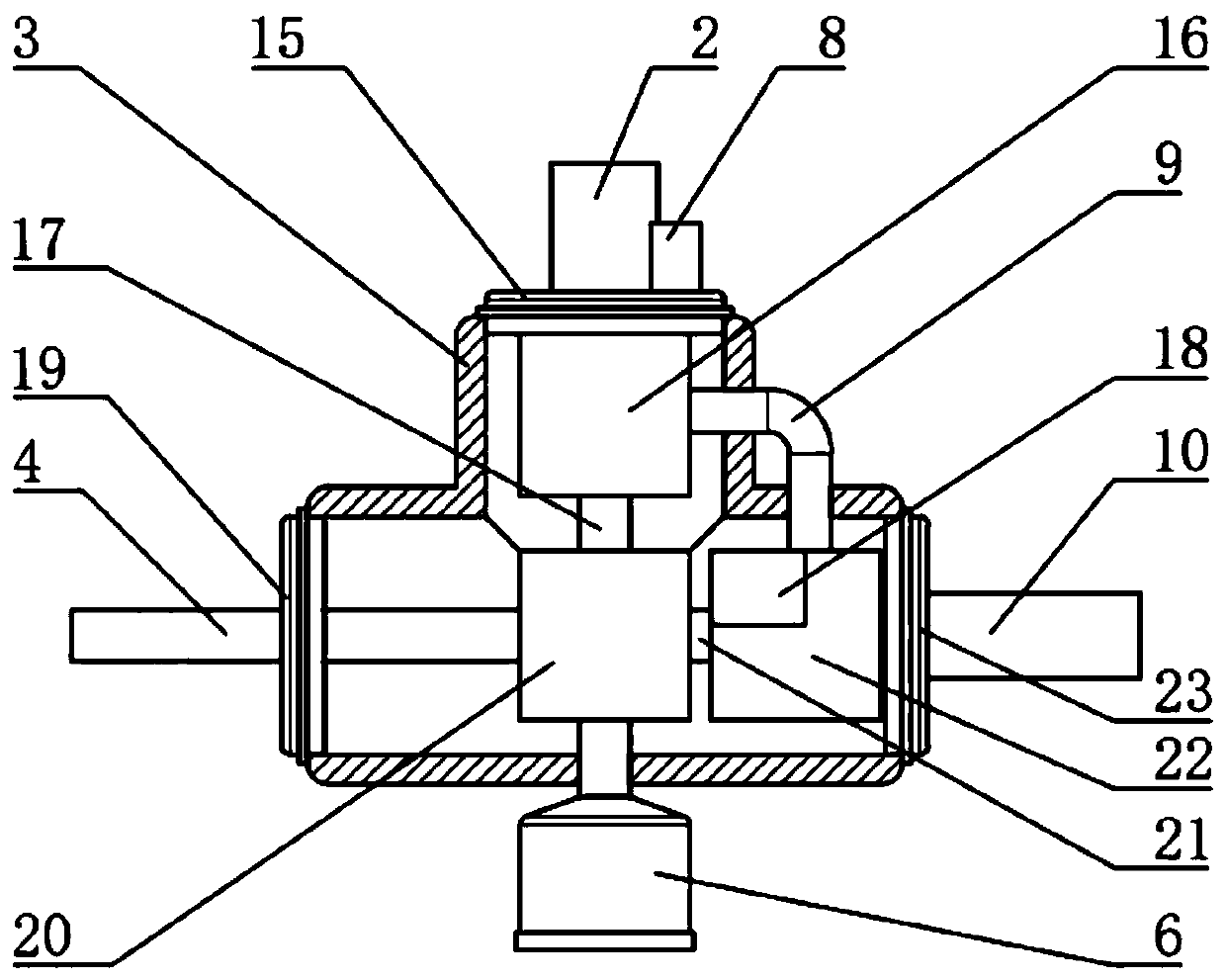

[0030] Such as Figure 1-3 As shown, a minimal quantity lubrication device includes a box body 7, a secondary atomization integrated pump 3 arranged in the box body 7, and an oil storage tank 1, a gas filter 12 and a gas filter 12 respectively arranged on the sides of the box body 7. The nozzle 5 and the oil storage tank 1 are connected to the secondary atomization integrated pump 3 through the oil delivery pipe 2, the gas filter 12 is connected to the secondary atomization integrated pump 3 through the gas delivery pipe 10, and the nozzle 5 is connected to the secondary atomization integrated pump 3 through the oil-gas mixture output pipe 4. The integrated pump 3 is connected. The secondary atomization integrated pump 3 includes a housing, an atomizer 16, a secondary atomizer 20, a micro gas booster 22 and an oil drop collection tank 6, the upper side of the atomizer 16 is connected with the oil delivery pipe 2, and the lower side passes through The oil mist output pipe 17 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com