Manufacturing system and method for absorbing articles

A manufacturing system and absorbent technology, which is applied in the field of disposable sanitary products, can solve the problems of not disclosing the specific structure of the water-absorbing particle application device, restricting the processing speed of the production line, and reducing the adhesion between layers, so as to achieve simple structure, Effects of cost reduction and improvement of absorptive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described below with reference to the drawings and specific embodiments of the specification.

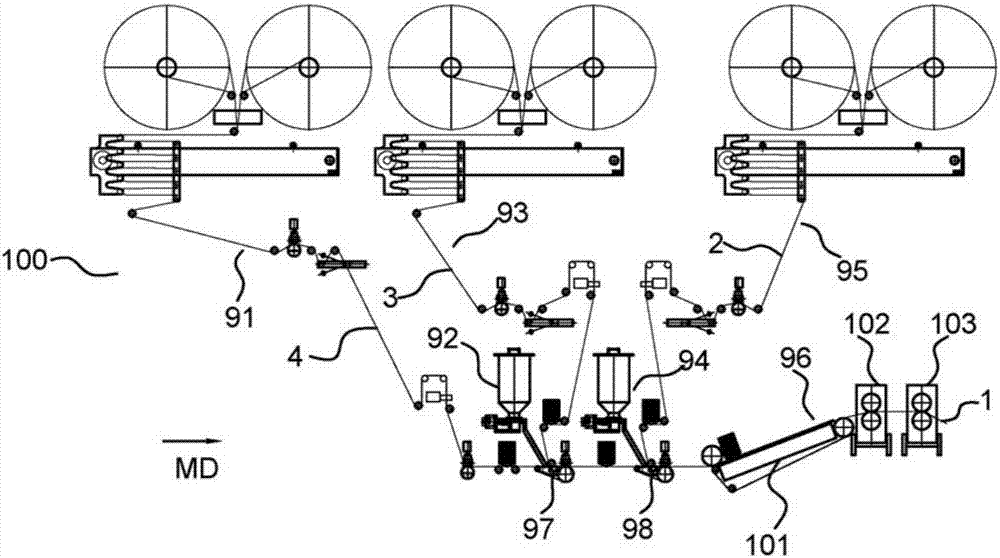

[0040] like figure 1 As shown, an absorbent article manufacturing system 100 is used for online manufacturing of a composite core 1 with superabsorbent resin particles A and C sprinkled at intervals, including:

[0041] - a first conveying unit 91 for conveying the first sheet 4 along the process direction MD;

[0042] - a second conveying unit 93 for conveying the second sheet 3 along the process direction MD;

[0043] - the first connecting station 97, the first connecting station 97 is used to arrange the second sheet 3 above the first sheet 4 to cover the first superabsorbent resin particles C, and make the first The sheet 4 is transported downstream along the process direction MD together with the second sheet 3;

[0044] - the second water-absorbent particle application device 92, which is located upstream of the first coupling station 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com