Coal mine working face coal seam GIM digital model creation method based on BIM

A technology of digital model and working face, applied in electrical digital data processing, 3D modeling, image data processing, etc., can solve problems such as inability to visually and accurately check the occurrence of coal seams, and achieve accurate control of coal production and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

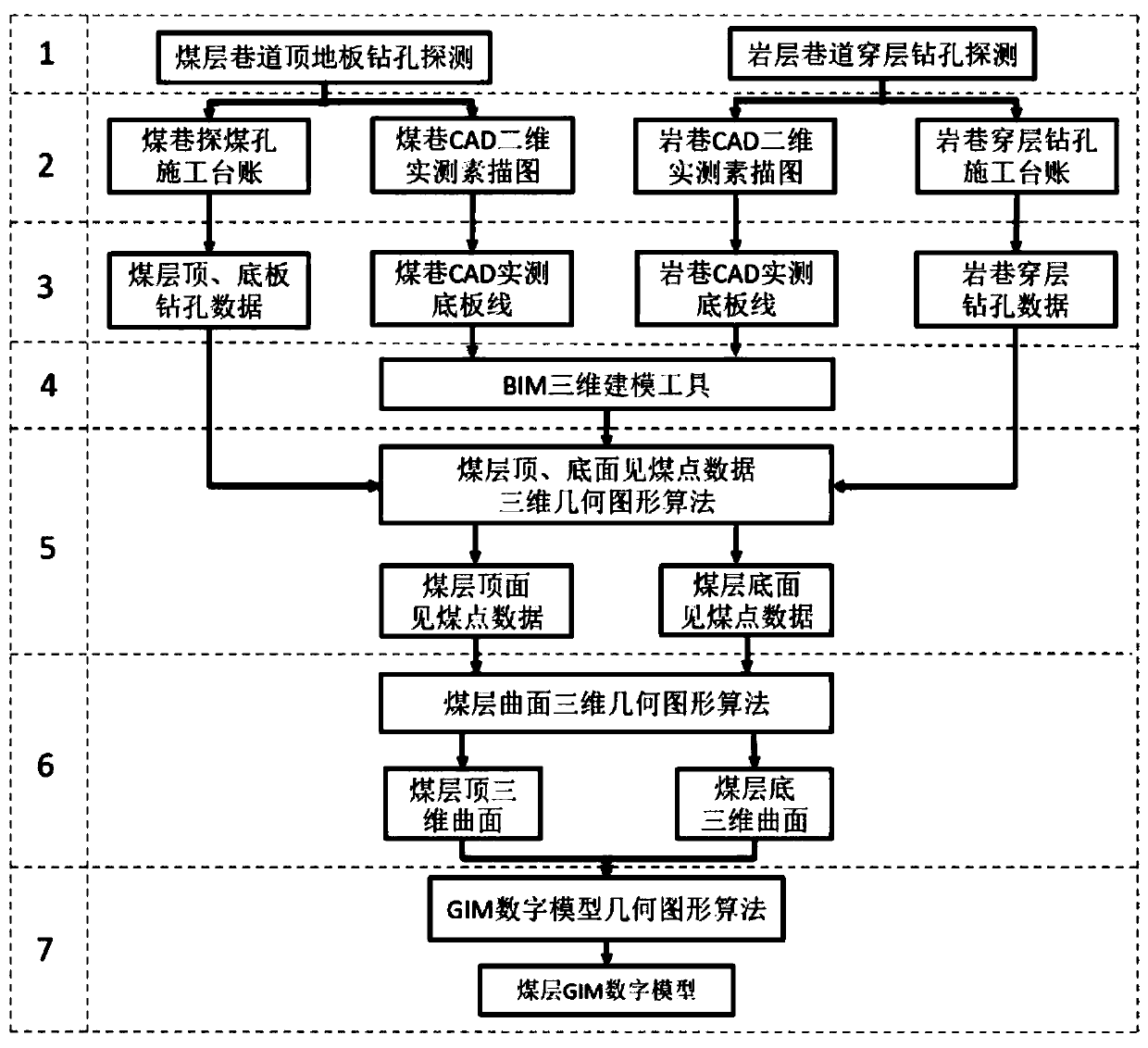

[0033] The method for creating a BIM-based coal seam GIM digital model of a coal mine working face in an embodiment of the present invention will be described in detail below. according to figure 1 The technical route shown is implemented.

[0034] Step 1: Use the underground coal seam roadway and rock layer roadway in the coal mine to conduct actual roadway measurement, and conduct multi-position, multi-angle, and multi-directional drilling methods to detect the occurrence of coal seams in the roadway of the proposed mining face; realize the detection of coal seam roadway roof floor drilling , and rock formation roadway penetration drilling detection.

[0035] The occurrence of coal seams or the use of underground precision geophysical equipment to detect the coal seams of the proposed mining face.

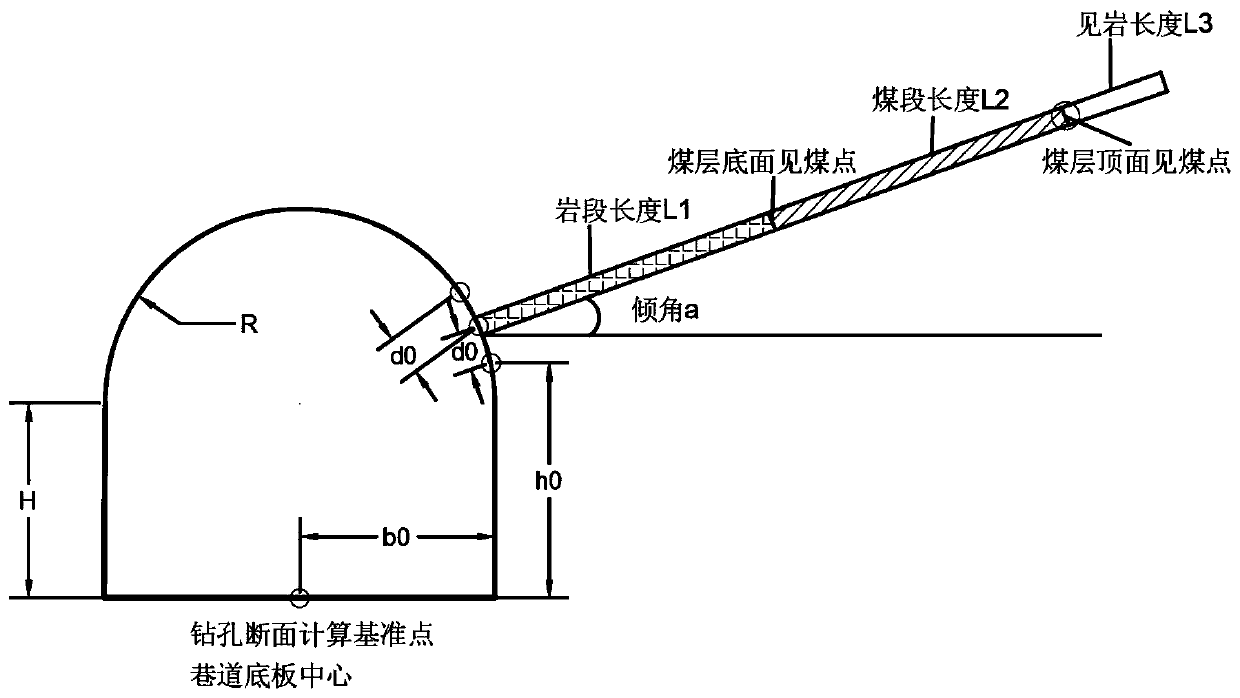

[0036] Step 2: Record the underground drilling construction ledger in detail, accurately record the drilling position, azimuth, inclination, drilling depth, coal penetration de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com