Manufacturing method of lightweight partition wall

A technology of lightweight partition board and production method, which is applied in the directions of chemical instruments and methods, manufacturing tools, hydraulic material layered products, etc. Day or even more than a month, long construction period and other problems, to achieve the effect of shortening production cycle, shortening curing time and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

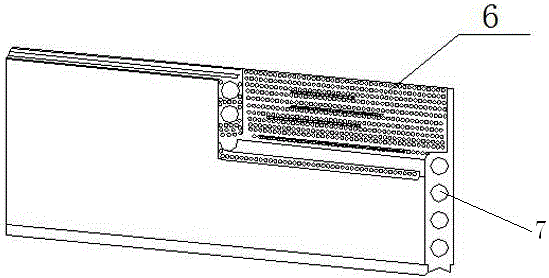

Image

Examples

Embodiment

[0031] This embodiment provides a method for manufacturing a lightweight partition wall panel, which includes the following steps:

[0032] (1) Set up a mold. The size of the mold can be designed as a standard size or customized as required. The mold has a raw material injection port; specifically, for example, according to common residential size standards, the standard size of the mold cavity can be selected as 3 Meters long, 60cm wide, 9cm thick rectangular parallelepiped, and one side of it is set to be fully open, so that the subsequent steel mesh and steel pipes and feed materials can be set;

[0033] (2) Mixing and stirring: all raw materials are mixed and stirred. The raw materials mainly include: 10 parts by weight of quick-drying cement, 35 parts by weight of fillers, 10.8 parts by weight of reinforcing fibers, 1 part by weight of granular beads, and 0.05 parts by weight of nano rubber powder , Wherein the particulate microbeads are microbead particles; the nano colloidal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com