Multi-layer mud filling method of Nixing ceramic

A technology of Nixing pottery and mud materials, applied in the field of multi-layer mud filling of Nixing pottery, can solve problems such as difficult to achieve, and achieve the effect of high yield and high artistic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

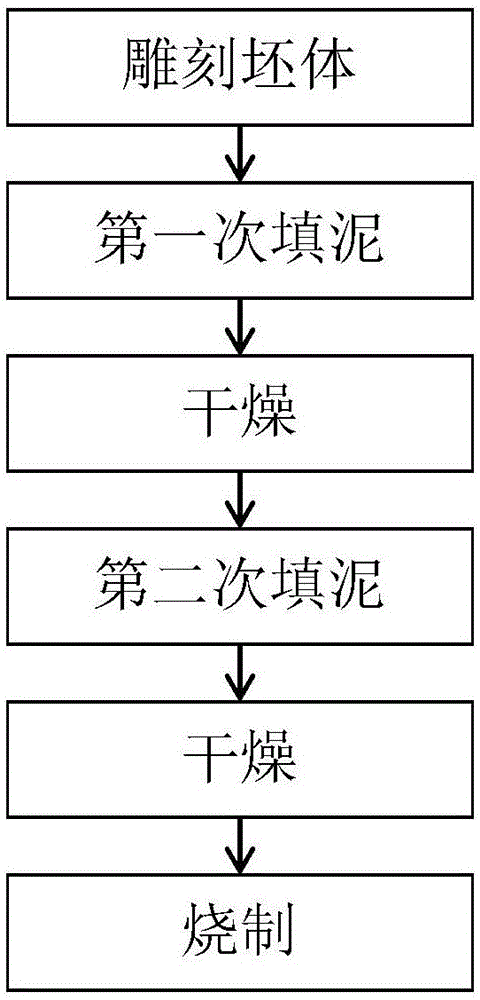

[0018] Such as figure 1 As shown, the steps include engraving on the green body, filling mud for the first time, drying, filling mud for the second time, drying and firing. The mud used for the first mud filling is colored soil and titanium dioxide powder in a mass ratio of 100 The ratio of :8 is adjusted to mix, and the mud used for the second mud filling is colored soil, titanium dioxide powder and table salt and adjusted to mix in a ratio of 100:1:2 by weight. The first mud filling is to fill the mud into the groove carved in the body without filling the groove. The second mud filling is to fill the mud into the groove carved in the body, and the first time to fill the mud At the same time, the thickness of the mud for the second filling is 0.3mm.

[0019] The first drying time is 6 days and the second drying time is 22 days.

[0020] The firing temperature of the first stage of firing is 1185°C and the firing time is 6.5 hours; the firing temperature of the second stage ...

Embodiment 2

[0022] The difference from Example 1 is that the mud used for the first mud filling is colored soil and titanium dioxide powder, which is mixed in a ratio of 100:6 by mass, and the mud used for the second mud filling is colored soil, titanium dioxide powder The powder and table salt are adjusted and mixed in a ratio of 100:2:2 by weight. The thickness of the mud for the second mud filling is 0.5mm.

[0023] The first drying time is 5 days and the second drying time is 25 days.

[0024] The firing temperature of the first stage of firing is 1200°C and the firing time is 6 hours; the firing temperature of the second stage is 1135°C and the firing time is 4 hours. After firing, keep warm for 25 minutes.

Embodiment 3

[0026] The difference from Example 1 is that the mud used for the first mud filling is colored soil and titanium dioxide powder mixed in a ratio of 100:5 by mass, and the mud used for the second mud filling is colored soil and titanium dioxide powder. Mix it with table salt in a ratio of 100:3:2 by weight. The thickness of the mud for the second mud filling is 0.3mm.

[0027] The first drying time is 10 days, and the second drying time is 20 days.

[0028] The firing temperature of the first stage of firing is 1200°C and the firing time is 6.5 hours; the firing temperature of the second stage is 1130°C and the firing time is 3 hours. After firing, keep warm for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com