Stacking machine capable of being stably operated to realize rapid transportation

A technology of stable operation and stacking machine, which is applied in the field of palletizing machine, can solve the problems such as stacking height is easy to overturn, the upper and lower layers are not aligned, and takes up a lot of space, so as to achieve fast hoisting speed, consistent rope shrinkage, and reduced space The effect of occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

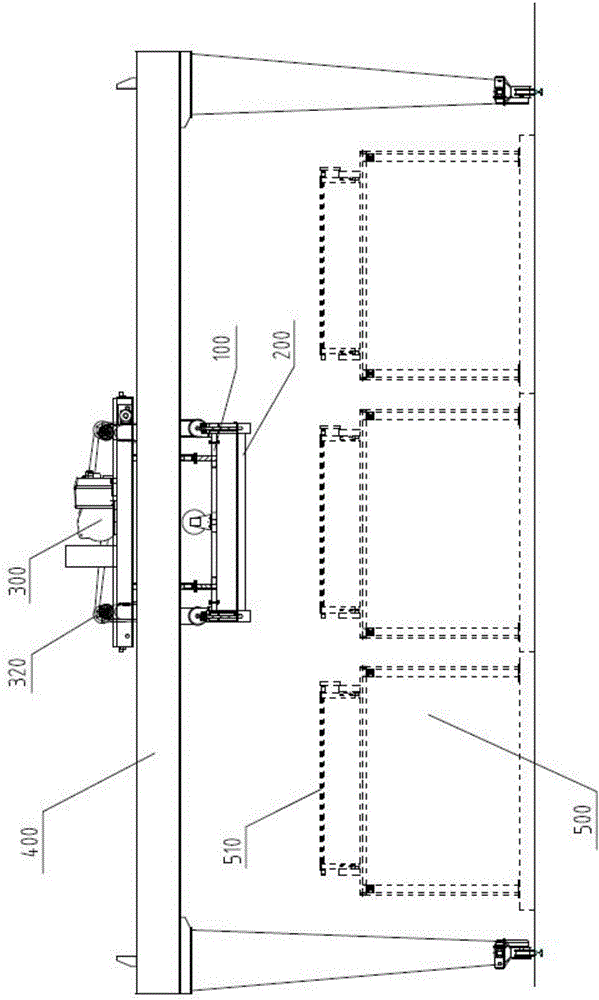

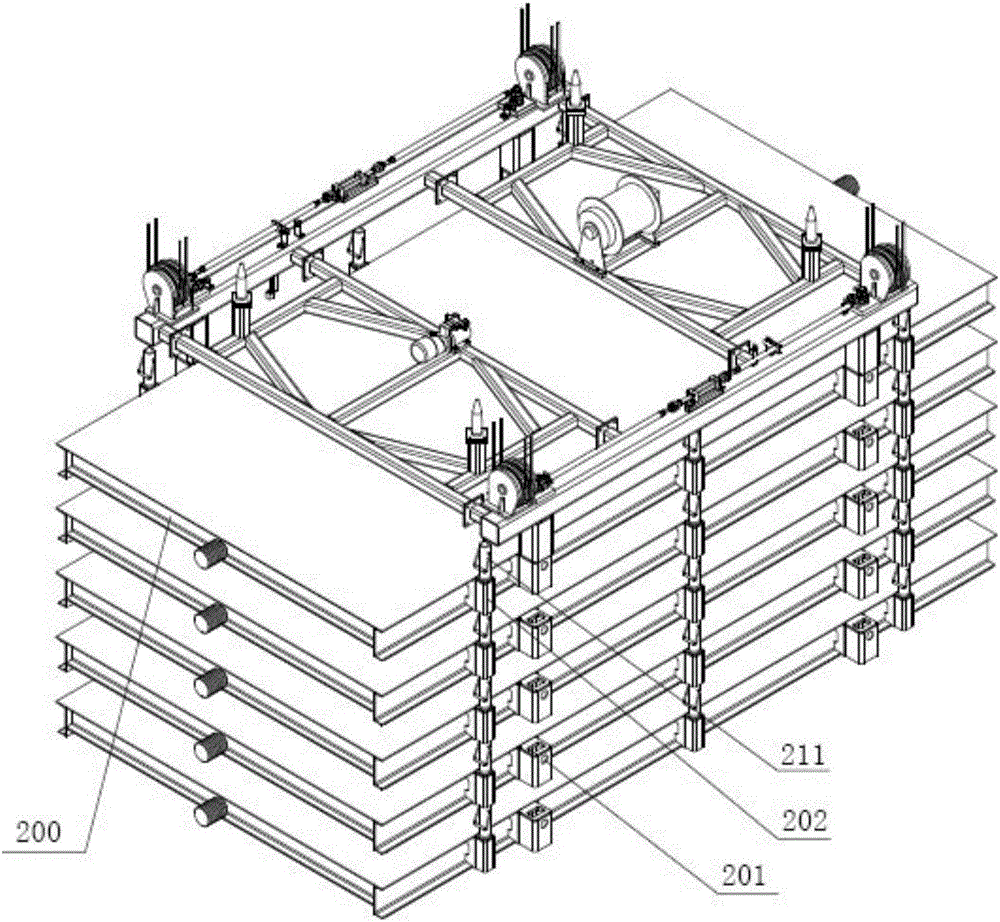

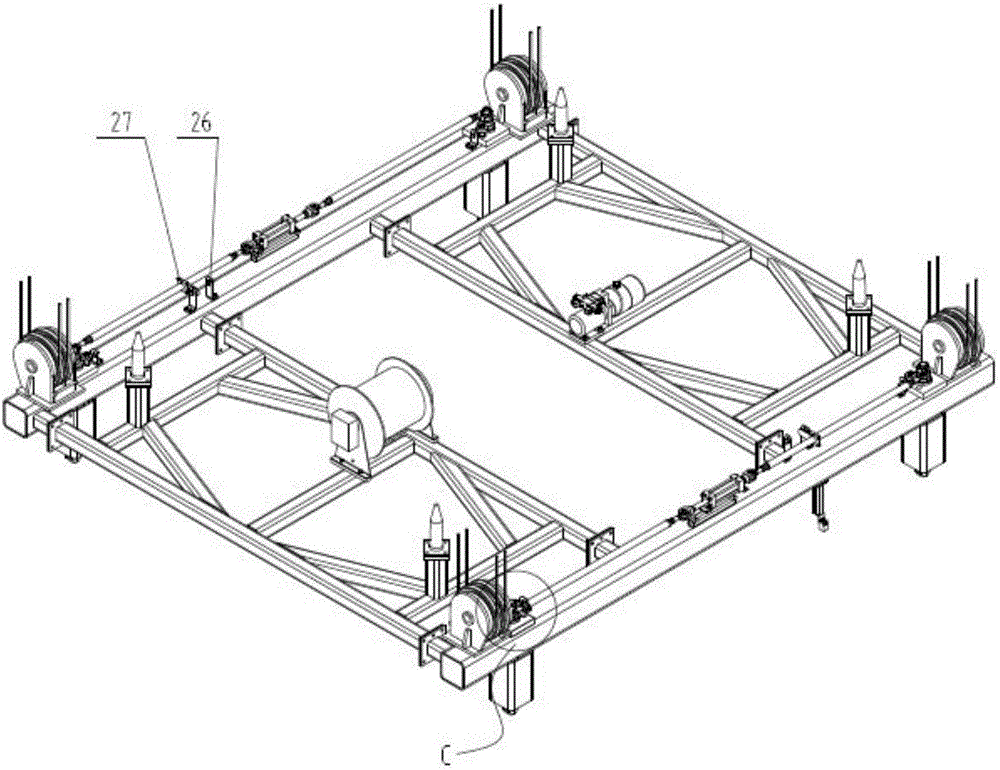

[0044] Such as Figure 1-11 As shown, a kind of palletizer that runs stably and realizes fast transshipment includes a hoisting mechanism and a palletizing tray 200 matched therewith. The driving mechanism 300 that the hoisting fixture 100 moves left and right; the driving mechanism 300 is provided with four first hoisting wheels 320 arranged in a rectangle, the hoisting fixture 100 includes a hoisting chassis of a rectangular frame, and the four corners of the upper end surface of the hoisting chassis There is a second hoisting wheel 10 connected to the first hoisting wheel 320; the left and right ends of the upper end surface of the hoisting chassis are provided with a turn lock mechanism along the edge of the hoisting chassis; the turn lock mechanism includes a turn lock assembly, a detection assembly and a double head Oil cylinder 20; both ends of the double-head oil cylinder 20 are connected with connecting rod 21, and the free end of connecting rod 21 is provided with a ...

Embodiment 2

[0053] Such as Figure 12-21 As shown, a kind of palletizer that runs stably and realizes fast transshipment includes a hoisting mechanism and a palletizing tray 200 matched therewith. The driving mechanism 300 for the left and right movement of the hoisting fixture 100; it is characterized in that: the driving mechanism 300 is provided with four first hoisting wheels 320 in a rectangular arrangement, and the hoisting fixture 100 includes a hoisting chassis of a rectangular frame. The four corners of the end surface on the frame are provided with the second hoisting wheels 10 connected to the first hoisting wheels 320; the left and right ends of the upper end surface of the hoisting chassis are provided with a turn lock mechanism along the edge of the hoisting chassis; The fixed rod 126 on the upper end surface of the underframe, the two ends of the fixed rod 126 are hinged with a turning block 127, and the opposite ends of the turning block 127 are respectively hinged with a ...

Embodiment 1 2

[0065] 1. The hanging at the four corners of the pallet tray 200 is driven by the same motor reducer, and there are four sets of ropes that are mechanically synchronized, which is different from ordinary cranes where each set of ropes is driven separately;

[0066] 2. The left and right directions of the rope system are designed to be completely geometrically symmetrical (including the groove on the rope reel 302), and the left and right directions are completely consistent;

[0067] 3. Each of the four sets of ropes has a turnbuckle bolt, which can easily achieve pre-leveling;

[0068] 4. The hoisting positioning column 40 cooperates with the positioning tube 310 of the driving mechanism 300, so that the equipment will not shake due to the inertia of starting and parking during the movement.

[0069] The present invention accurately picks up the palletizing tray 200 and accurately places it at a predetermined position.

[0070] Embodiment one

[0071] 1. During the descent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com