Magnetron cathode assembly and silicon-molybdenum solder integrated preparation method

A magnetron cathode and solder technology, which is used in electrode assembly manufacturing, thermionic cathode manufacturing, metal processing equipment, etc. The effect of automated production, stable production process and quality, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

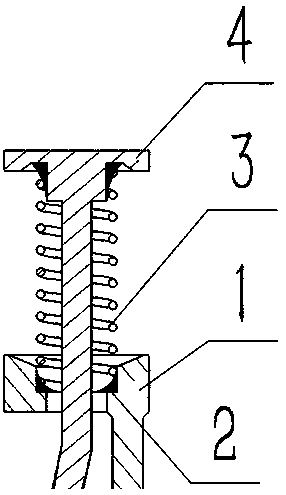

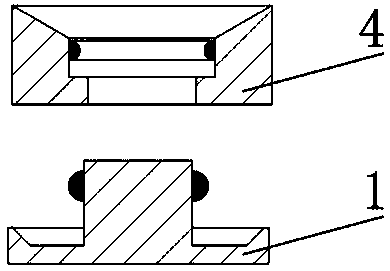

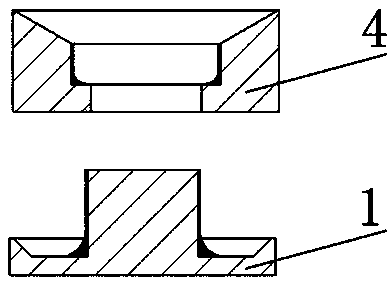

[0014] A preparation method for the integration of magnetron cathode assembly and silicon-molybdenum solder, the steps are as follows: (1) material selection and proportioning: molybdenum powder with an average particle size of 3 μm and silicon powder with an average particle size of 1 μm are selected as solder raw materials, Weigh 10g of silicon powder and 100g of molybdenum powder according to the weight ratio of 1:10; (2) Grinding and mixing: add the powder with a good proportion to the planetary ball mill for grinding for 36 hours, the ball milling medium is agate ball, the weight is 1.2kg, the ball The material ratio is 10:1, the ball milling atmosphere is Ar, and the ball milling speed is set at 380r / min. (3) Sieving: After grinding, sieve the powder and grinding balls, pass the powder through a 300-mesh sieve, and take the sieve for use. The entire operation process must be carried out under vacuum or argon protection to prevent powder Oxidation occurs when exposed to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com