Feeding structure of die and die employing same

一种模具、进浇的技术,应用在塑胶模具进浇结构及应用该进浇结构的模具领域,能够解决限制塑胶流量、影响生产效率、收缩不均等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The pouring structure of the mold of the present invention takes injection molding as an example.

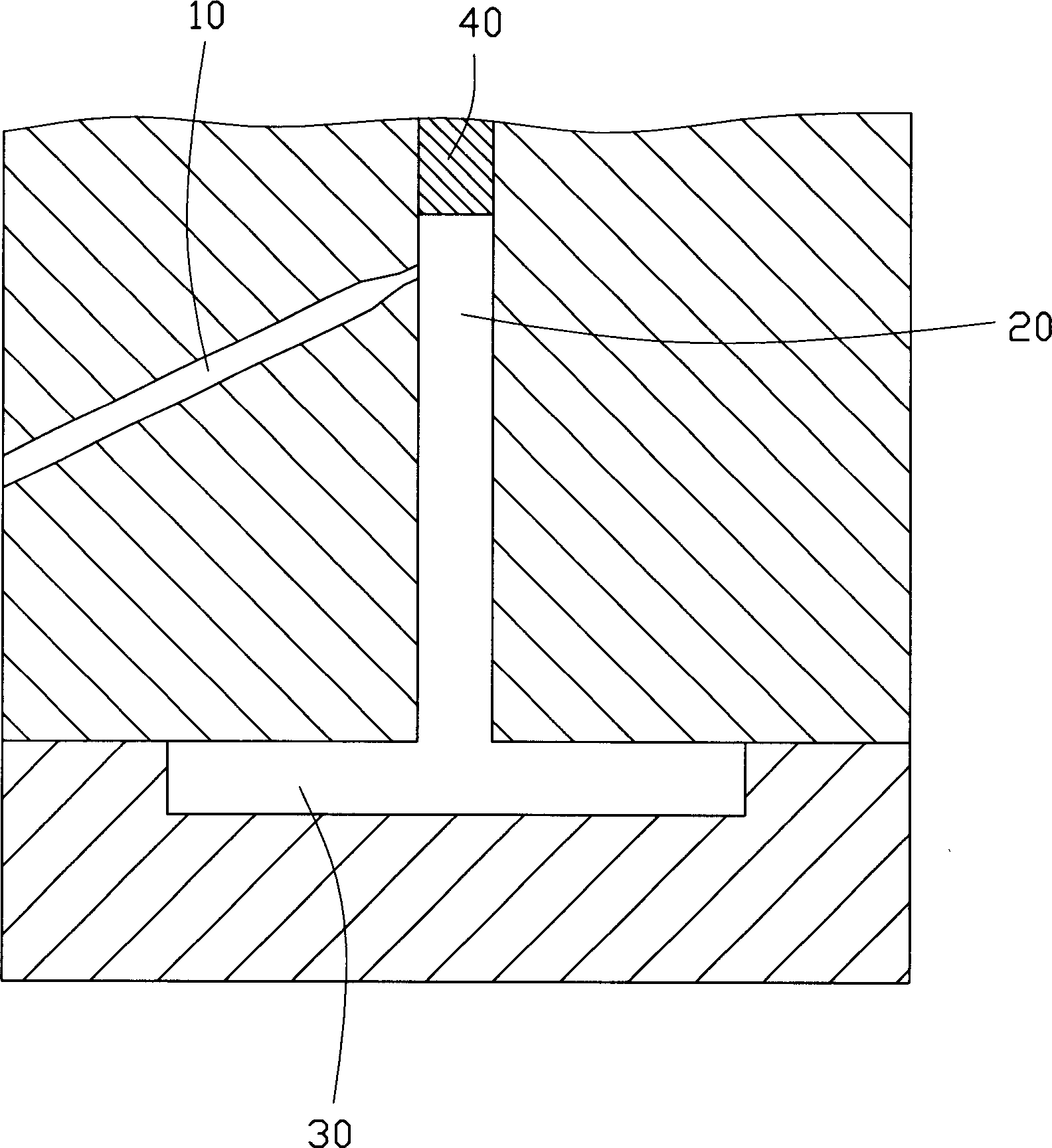

[0020] For the preferred implementation mode of the mold pouring structure of the present invention, please refer to Figure 2 to Figure 4 , the mold includes an upper mold 1 and a lower mold 2, and a parting surface 12 is formed between the upper mold 1 and the lower mold 2.

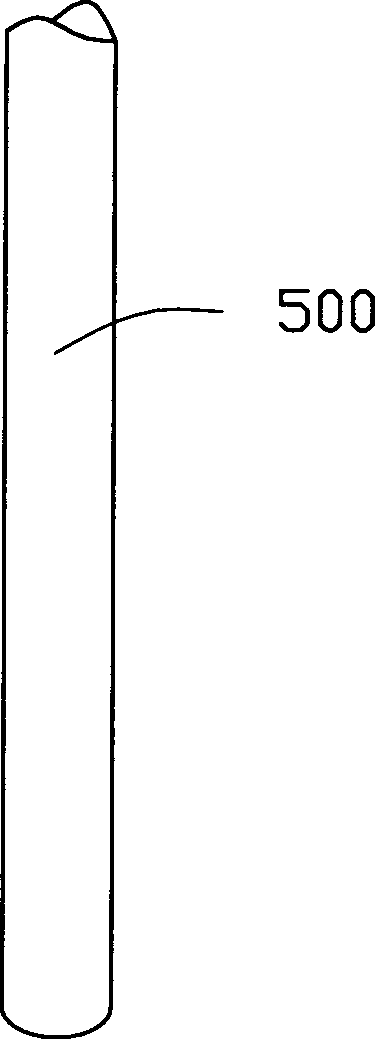

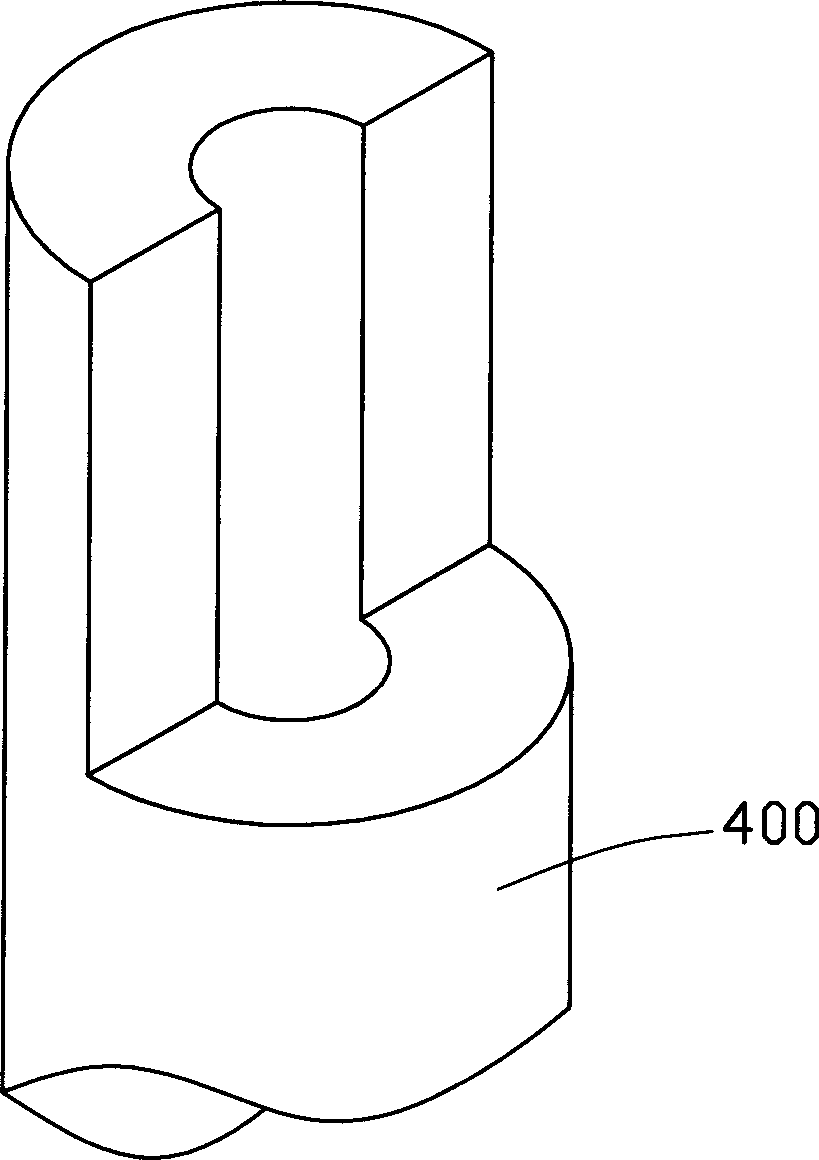

[0021] The upper mold 1 is provided with a pouring structure, and the lower mold 2 is provided with a cavity 300, and the cavity 300 is used to form molten plastic into a product. The gate structure includes a latent gate area 100 , a columnar gate area 200 , a thimble sleeve 400 and a thimble 500 .

[0022] The latent gate area 100 is connected to the columnar gate area 200 at a certain angle. After injection molding, the plastic in the latent gate area 100 can form a waste, and the waste can pass through the formed shear during demoulding or parting. Force, the gate waste is automatically cut o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com