Composite ceramic tile with smooth glaze and manufacturing method

A production method and a smooth technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems such as uneven surface of dry-processed powder brick adobe, and achieve the effects of preventing delamination, reducing costs, and reducing the cost of ceramic tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

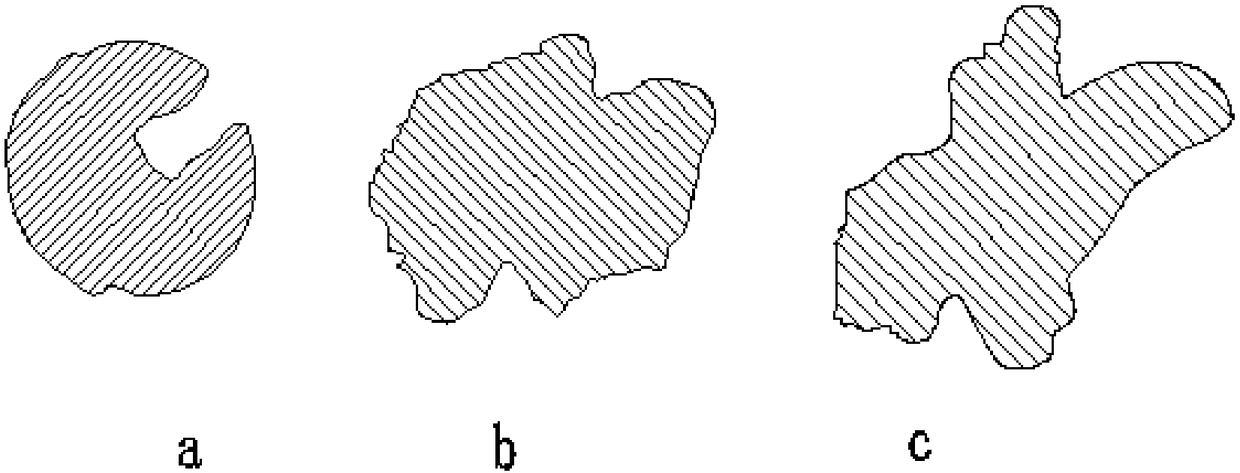

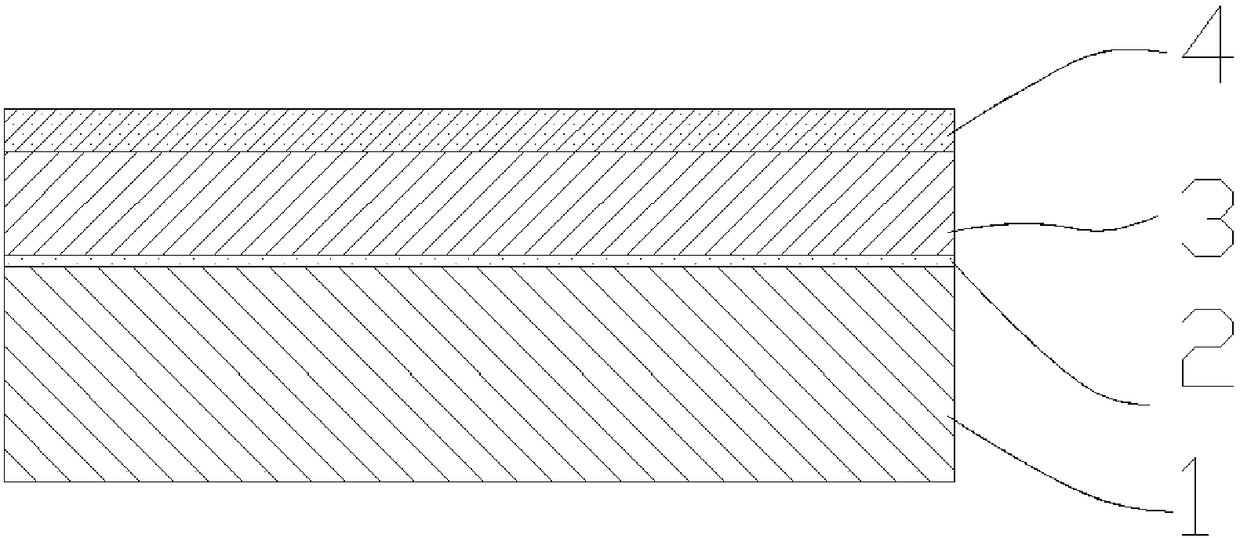

[0056] A composite ceramic tile with a smooth glaze, comprising a first body, an adhesive layer, a second body and a glaze layer arranged sequentially from bottom to top, the first body and the second body are bonded through the adhesive layer, The first green body is formed by pressing powder obtained by dry milling, and the second green body is formed by pressing powder obtained by wet milling.

[0057] The thickness of the first green body is 5 mm, and the thickness of the second green body is 5 mm.

[0058] The adhesive layer is a slurry layer, and the application amount of the slurry is 55g / m 2 .

[0059] The manufacturing method of above-mentioned smooth glazed composite ceramic tile comprises the following steps:

[0060] (1) Making the first green body: the powder is obtained by dry powder milling, and the powder is pressed and formed into the first green body by a press. The pressing pressure of the first green body is 220Mpa, and the strength of the first green bod...

Embodiment 2

[0066] A composite ceramic tile with a smooth glaze, comprising a first body, an adhesive layer, a second body and a glaze layer arranged sequentially from bottom to top, the first body and the second body are bonded through the adhesive layer, The first green body is formed by pressing powder obtained by dry milling, and the second green body is formed by pressing powder obtained by wet milling.

[0067] The thickness of the first green body was 10 mm, and the thickness of the second green body was 3 mm.

[0068] The adhesive layer is a slurry layer, and the application amount of slurry is 100g / m 2 .

[0069] The manufacturing method of above-mentioned smooth glazed composite ceramic tile comprises the following steps:

[0070] (1) Making the first green body: the powder is obtained by dry milling, and the powder is pressed and formed into the first green body by a press. The pressing pressure of the first green body is 200Mpa, and the strength of the first green body is 1....

Embodiment 3

[0076] A composite ceramic tile with a smooth glaze, comprising a first body, an adhesive layer, a second body and a glaze layer arranged sequentially from bottom to top, the first body and the second body are bonded through the adhesive layer, The first green body is formed by pressing powder obtained by dry milling, and the second green body is formed by pressing powder obtained by wet milling.

[0077] The thickness of the first blank was 8 mm, and the thickness of the second blank was 5 mm.

[0078] The bonding layer is a composite mud layer, and the composite mud layer is formed by the composite mud; the formula of the composite mud comprises in weight percent: sodium hydroxycellulose 2%, ethylene glycol 5%, kaolin 37%, attapulgite 15% and Water 38%. The application amount of composite mud is 55g / m 2

[0079] The manufacturing method of above-mentioned smooth glazed composite ceramic tile comprises the following steps:

[0080] (1) Making the first green body: the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus of rupture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com