Die

A mold and template technology, which is applied in the field of wedge-shaped light guide plate injection molding molds, can solve the problems affecting the size uniformity and optical performance of the light guide plate, the difference in the shrinkage degree of the wedge-shaped light guide plate, and the warping deformation of the wedge-shaped light guide plate. Improve dimensional uniformity and optical performance, small dimensional error, and consistent shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The mold of the technical solution will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

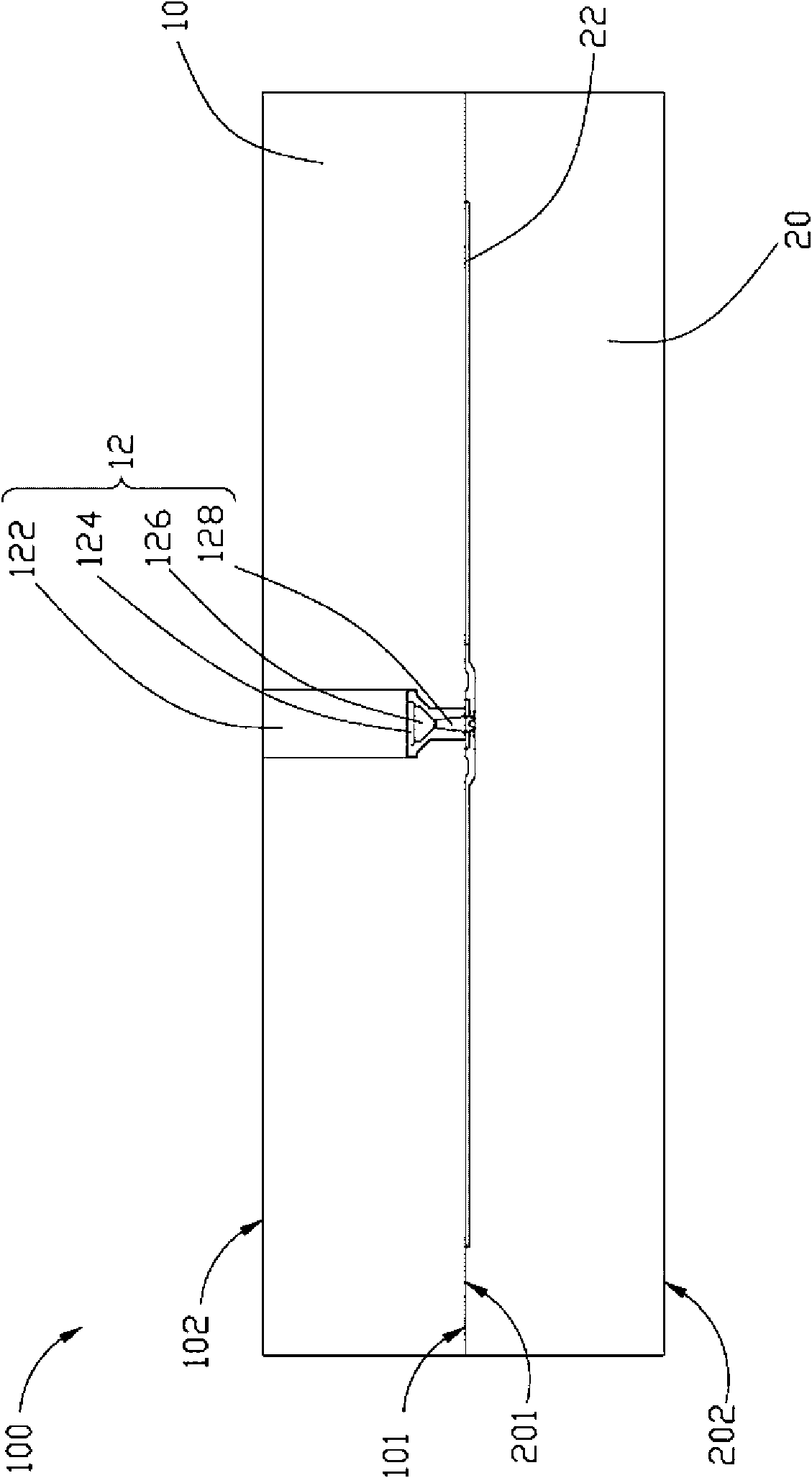

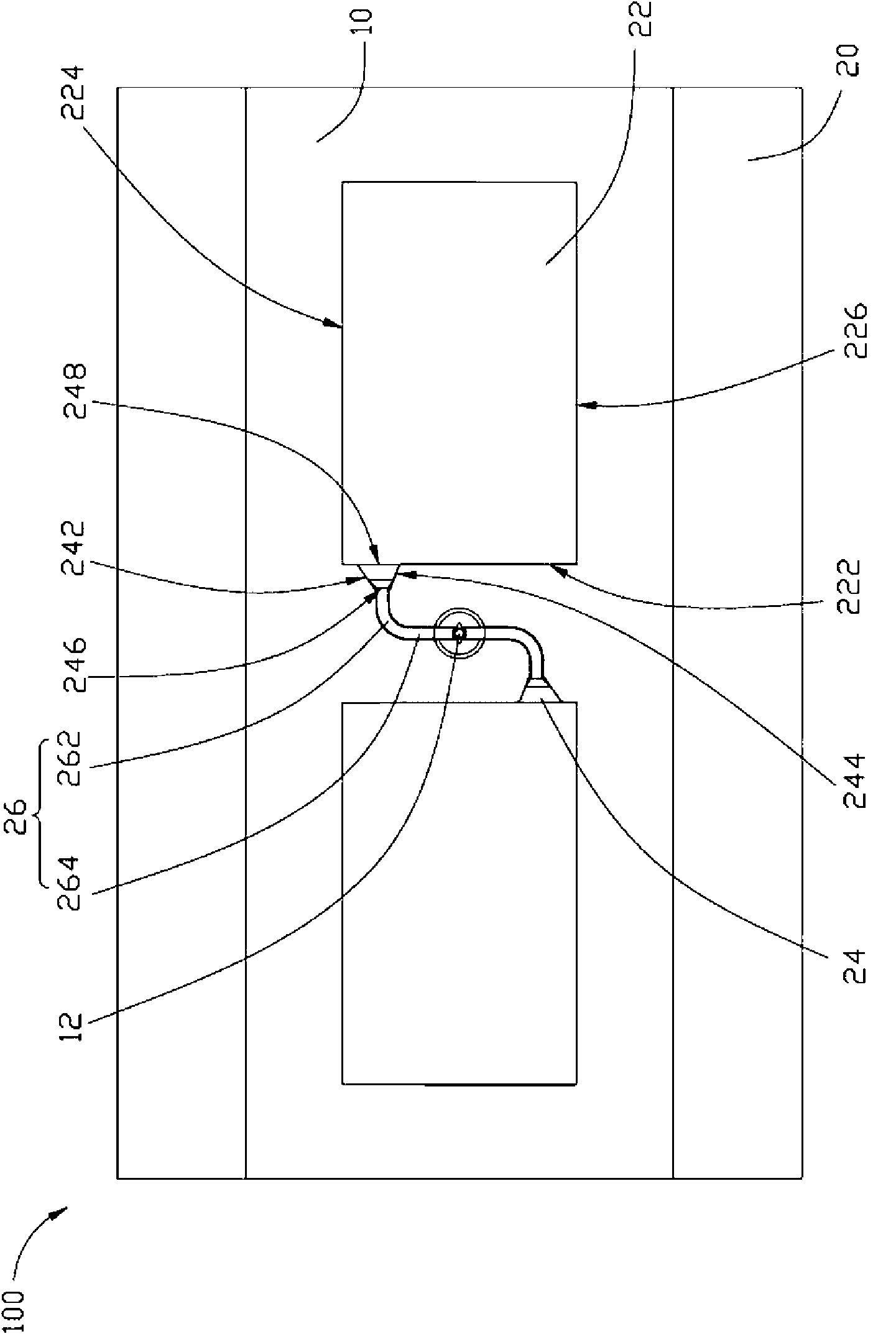

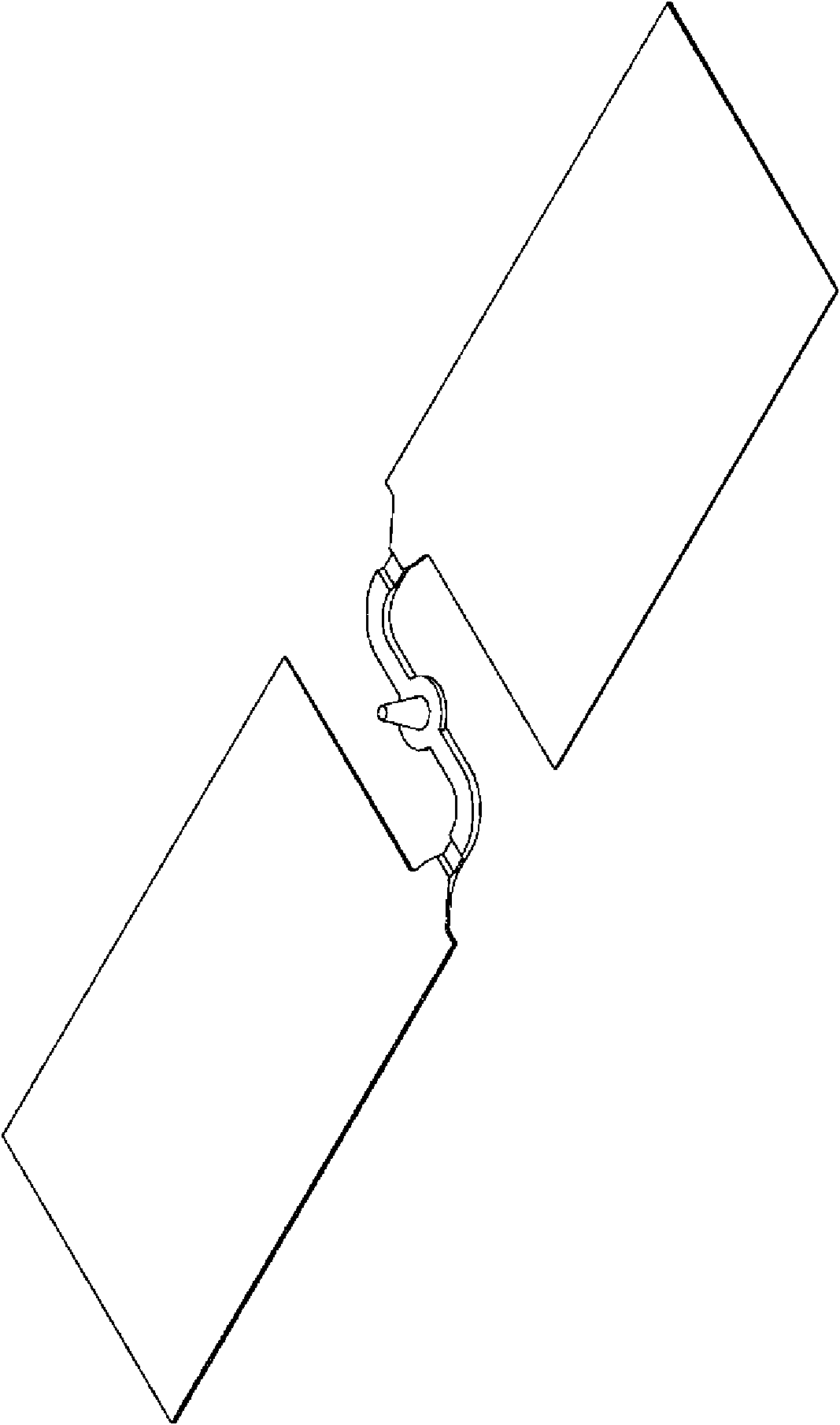

[0014] see figure 1 and figure 2 , The mold 100 provided by the embodiment of the technical solution includes a first template 10 and a second template 20 .

[0015] The first template 10 has a first surface 101 and a second surface 102 opposite to each other. The first surface 101 is opposite to the second template 20 , and the second surface 102 is away from the second template 20 . The first template 10 defines a main channel 12 inwardly from the first surface 101 . The main channel 12 runs through to the second surface 102 . The sprue 12 is used for injection molding of molten plastic.

[0016] In this embodiment, the main channel 12 includes a straight section 122 , a buffer section 124 , a constriction section 126 and an expansion section 128 connected in sequence. Wherein, the straight-line section 122 is opened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com