Aluminum oxide ceramic substrate with high heat conductivity and preparation method thereof

An alumina ceramic, high thermal conductivity technology, applied in the field of ceramic materials, can solve the problems of large one-time investment, non-compliance with energy saving and emission reduction, high operation and maintenance costs, and achieve consistent shrinkage rate, consistent thickness, and stable physical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

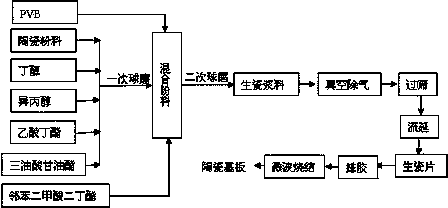

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh 200g of ceramic powder with an electronic balance, of which alumina powder accounts for 96%, additives 4%, of which 2g silicon dioxide, 1.5g magnesium oxide, 1.5g titanium dioxide, 2g zirconium dioxide and 1g yttrium oxide The PVB powder that weighs 14g; The butanol that weighs 60g, weighs 30g Virahol, weighs 30g butyl acetate; The DBP that weighs 12g; 30g triolein;

[0026] (2) Put the three solvents of butanol, isopropanol and butyl acetate that have been weighed into the ball mill tank;

[0027] (3) Add the weighed ceramic powder into the solvent, then add an appropriate amount of zirconia balls, put them into a ball mill for ball milling, and mill at room temperature for 24 hours;

[0028] (4) In the ball mill tank, put the weighed DBP and PVB powders into the mixed powder, then put them back in the ball mill, and ball mill at room temperature for 36 hours;

[0029] (5) Stir and degas the ball-milled raw porcelain slurry for 40 minutes in a low vacuum env...

Embodiment 2

[0037] The steps of this example are exactly the same as Example 1, the difference is that in step (1), 200g of ceramic powder is weighed with an electronic balance, wherein alumina powder accounts for 96%, auxiliary agent 4%, wherein 2g of silicon dioxide, 1.5g magnesia, 1.5g titanium dioxide, 2g zirconia and 1g yttrium oxide; weigh 8g of PVB powder; weigh 50g of butanol, weigh 15g of isopropanol, weigh 15g of butyl acetate; weigh 4g of DBP; weigh 4g of triolein; the ball milling time in step (3) is 12h; the ball milling time in step (4) is 40h, the degassing time in step (5) is 30min, and the gel removal temperature in step (10) is 400°C, and the heating rate is 40°C / h; in step (11), the sintering temperature is 1450°C, the sintering time is 2h, and the heating rate is 400°C / h. The resulting substrate density is 3.80 g / cm 3 , the bending strength can reach 322 MPa, the thermal conductivity is 25.4W / m K, the dielectric constant is 9.68 at 10GHz, and the dielectric loss tang...

Embodiment 3

[0039] The steps of this example are exactly the same as Example 1, the difference is that: (1) weigh 200g of ceramic powder with an electronic balance, of which alumina powder accounts for 96%, additives 4%, of which 2g of silicon dioxide, 1.5 g magnesia, 1.5 g titania, 2 g zirconia and 1 g yttrium oxide; weigh 30 g of PVB powder; weigh 80 g of butanol, weigh 160 g of isopropanol, weigh 160 g of butyl acetate; weigh 26 g of DBP ; Weigh the triolein of 8g. The ball milling time in step (3) is 6 hours; the ball milling time in step (4) is 48 hours, the degassing time in step (5) is 60 minutes, the debinding temperature in step (10) is 600°C, and the heating rate is 80°C / h; In step (11), the sintering temperature is 1550°C, the sintering time is 0.5h, and the heating rate is 900°C / h. The resulting substrate density was 3.84 g / cm 3 , the bending strength can reach 351 MPa, the thermal conductivity is 26.7W / m K, the dielectric constant is 9.95 at 10GHz, and the dielectric loss ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com