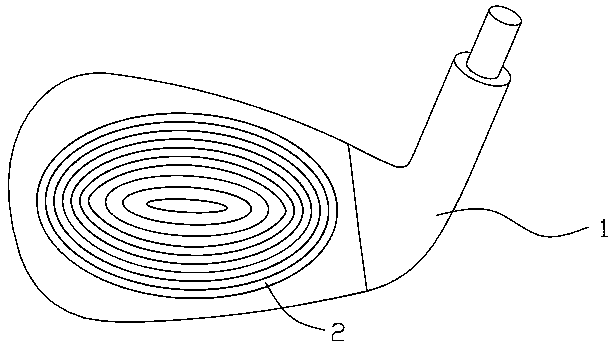

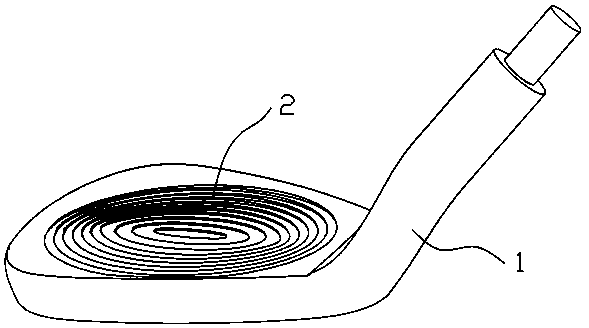

Golf club head

A golf head and hitting surface technology, which is applied to golf balls, golf clubs, rackets, etc., can solve the problems that the quality of the club is easily affected by human factors, the assembly process is complicated, the components are many, and the like. Good hitting effect, ensure consistent shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

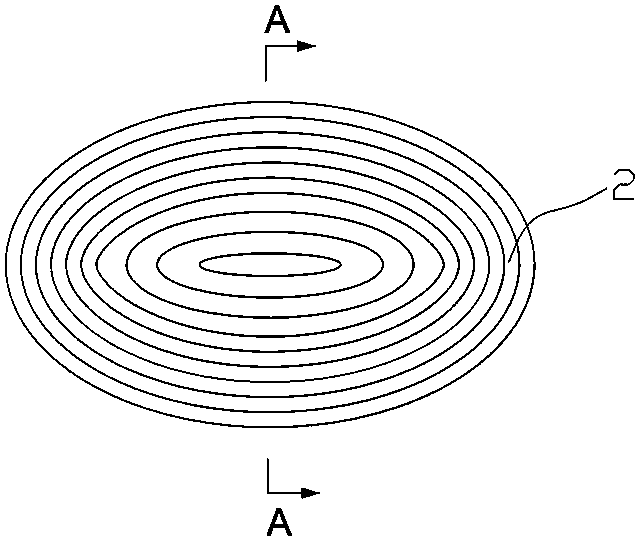

[0053] Embodiment one, as attached Figure 4 As shown, the golf head has a hollow structure, the hitting surface is flat, and the cross-section of the force-bearing rib is tooth-shaped 21. At this time, the cross-section of the golf head is comb-tooth-shaped.

Embodiment 2

[0054] Embodiment two, as attached Figure 5 As shown, the golf head has a hollow structure, the hitting surface is flat, and the cross-section of the stress rib is arched. At this time, the cross-section of the golf head is bow-shaped.

Embodiment 3

[0055] Embodiment three, as attached Figure 6 As shown, the golf head is hollowed out, the hitting surface is flat, the cross section of the stress rib 21 is arched, and the edges of the stress rib are rounded. At this time, the cross section of the golf head is a bow connection. shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com