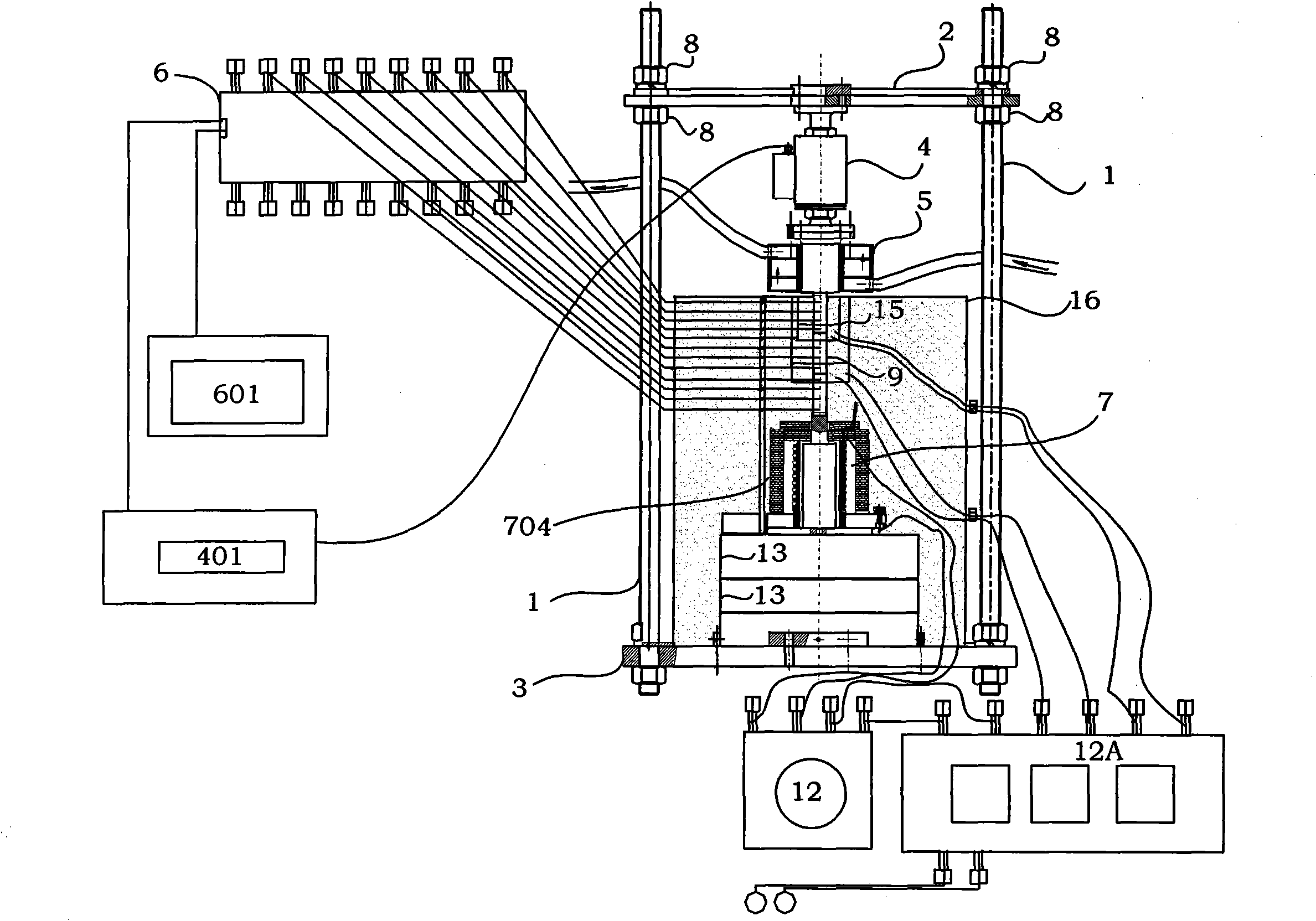

Thermal contact resistance testing device with cooling device

A cooling device and contact thermal resistance technology, applied in the field of testing, can solve the problems of impractical engineering, many parameters, large errors, etc., to avoid errors, improve work efficiency, and avoid lateral heat flow loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

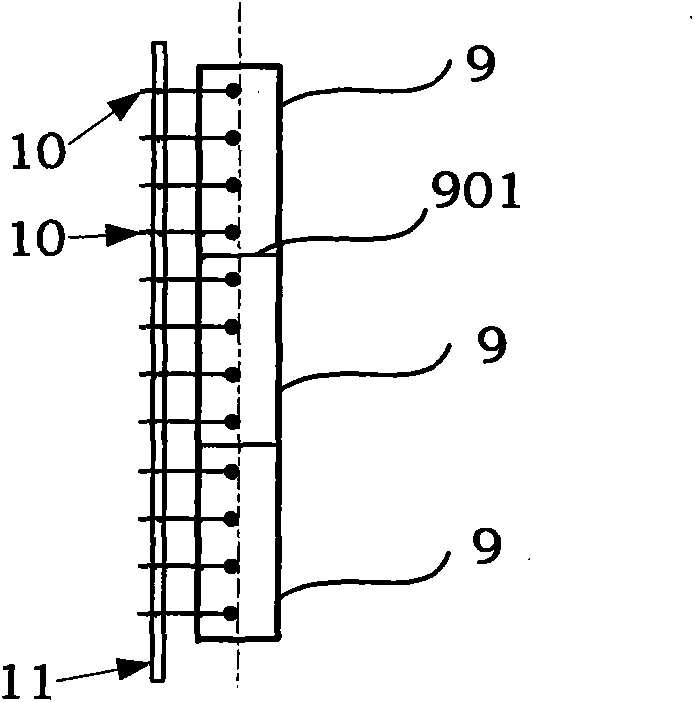

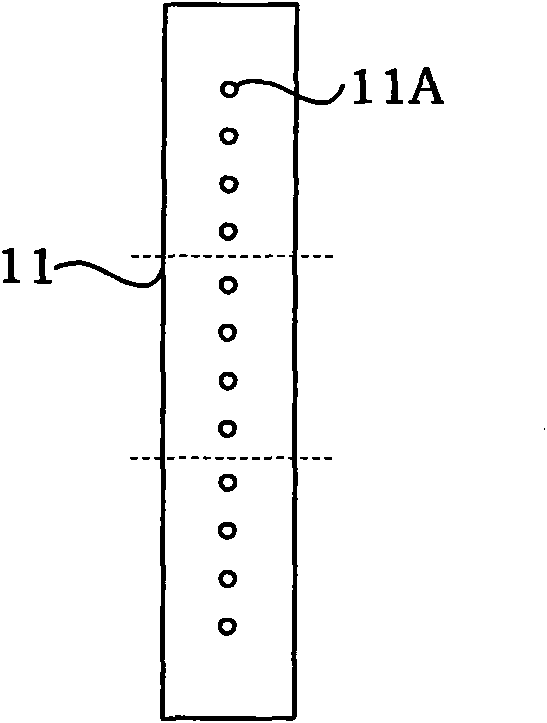

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] The invention provides a method for testing thermal contact resistance. The testing method utilizes the characteristics of temperature change of heat flow transmitted between different material interfaces to detect thermal contact resistance of the interface. Therefore, this method is relatively simple, reliable, and has high measurement accuracy and is easy to use. Operational test equipment will do. However, due to the need for sufficient heat exchange between the temperature measuring element and the surrounding medium, it takes a certain amount of time to achieve thermal equilibrium, so the data after reaching a steady state is credible. Based on the above factors, the contact thermal resistance testing method provided by the present invention is specifically realized through the following steps:

[0025] The first step is the preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com