Ship model full circle swinging pushing device

A full-turn propulsion and ship model technology, which is applied in steering and steering with propulsion components, can solve the problems of inability to obtain test results, harsh requirements, small push torque, etc., and achieve good test results, compact structure, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

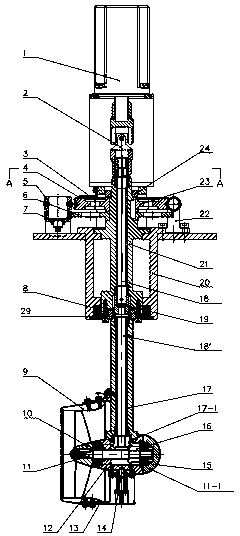

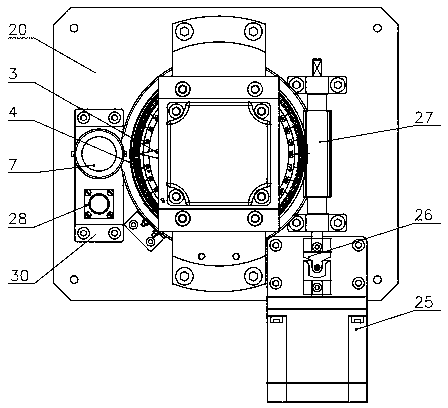

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the present invention consists of an axial transmission mechanism and a circumferential rotation mechanism;

[0025] The axial transmission mechanism includes an upper section inner shaft 18 that runs through the installation base 20. One end of the upper section inner shaft 18 is connected to the first servo motor 1 through a universal coupling 2, and the other end extends out of the installation base 20. And connect one end of the inner shaft 18' of the lower section through the transition sleeve 19, the other end of the inner shaft 18' of the lower section is connected with the horizontal transmission shaft 11 through the bevel gear 16, one end of the horizontal rotation shaft 11 is fixedly connected with the propeller 10, and is located on the horizontal transmission shaft The other end of 11 also ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com